Automotive protective cover

A technology for automobiles and protective covers, which is applied to vehicle parts, removable outer sheaths, layered products, etc., and can solve problems such as inability to effectively prevent sharp objects from being cut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

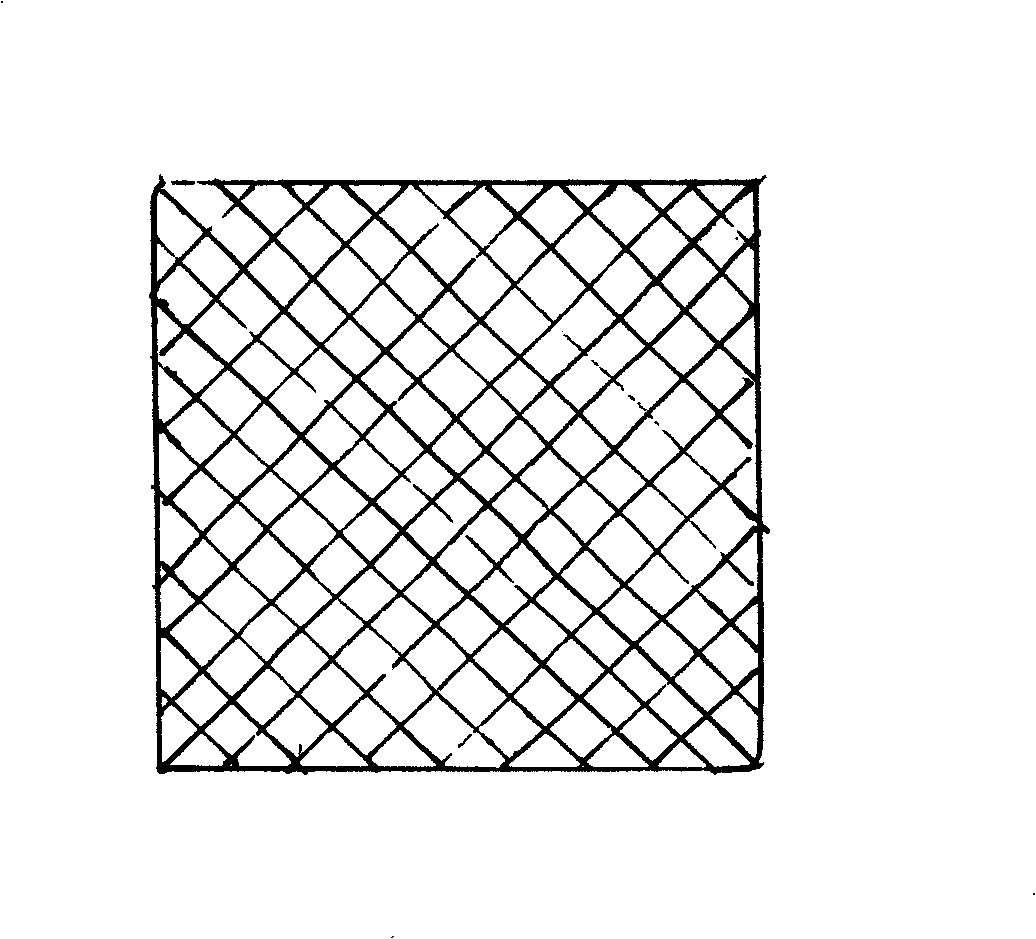

[0011] Example 1, the present invention discloses a car protective cover. like figure 1 The surface material shown is made of single-color or multi-color high-density PVC sub-spun material, which is characterized by rainproof, snowproof, dustproof, high temperature resistance, and light weight. The bottom material is made of high-density PVC sub-spun material, and the middle layer is made of wire mesh or high-elasticity high-toughness chemical material. The wire is very thin, such as figure 2 Its function is to effectively prevent sharp objects from being cut and completely solve the problem of car scratches. The specific production method is to cut the wire mesh into a square according to the different specifications of the car body. When sewing the bottom layer of the protective cover, install a nylon pull button on the top of the broken grid, so that it is very convenient to put the wire mesh in and out.

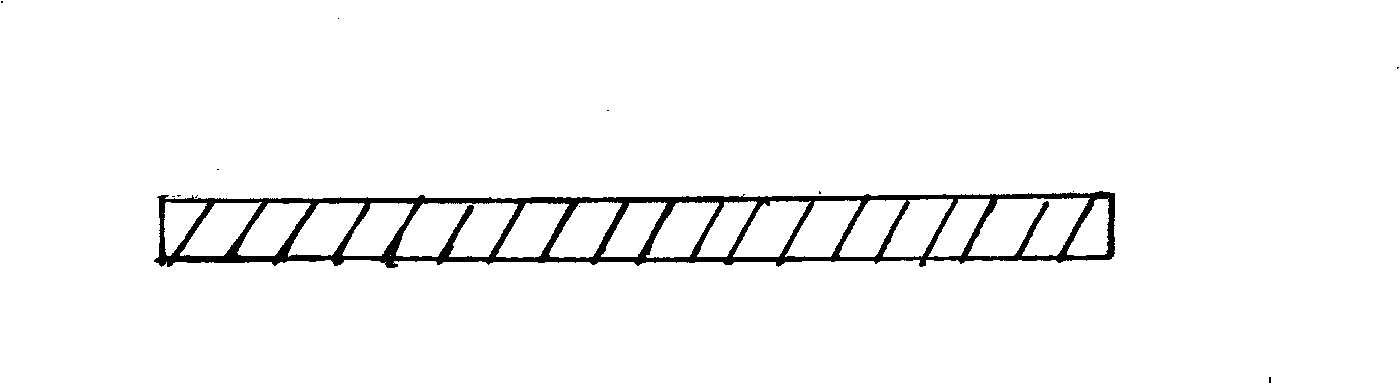

[0012] image 3 Shown invention protective cover closing edge pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com