Cable production device

A technology for producing devices and cables, applied in the direction of wire drawing dies, etc., can solve the problems of the wire core unable to keep the center line of the wire drawing die hole level, unable to automatically calibrate, and the wire core scratching, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

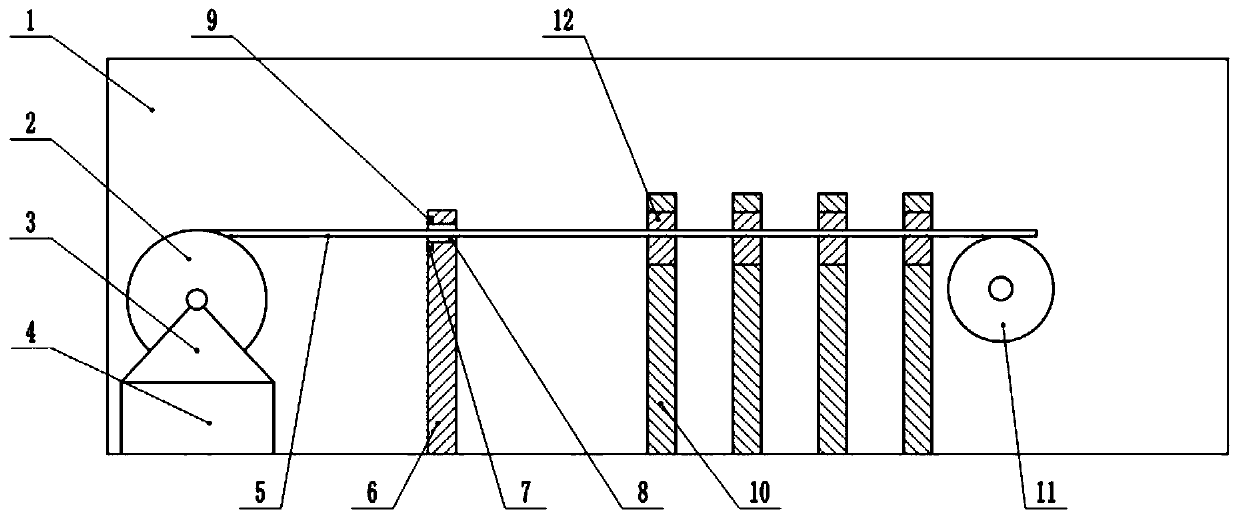

[0038] Embodiment one is basically as attached figure 1 Shown: the production device of the cable, including the motor and the housing 1, and the housing 1 also includes a coiling mechanism, a positioning calibration mechanism and a wire pulling mechanism from left to right. The winding mechanism includes, from top to bottom, a winding wheel 2 for winding the wire core 5, a base 3 for supporting the winding wheel 2, and a telescopic cylinder 4 for lifting the base 3, and the lower end of the telescopic cylinder 4 is fixedly connected by screws. At the inner bottom of the housing 1, the telescopic cylinder 4 is used to push the upper end of the base 3 up and down, and the bottom of the base 3 is fixedly connected together by screws. 4 Model: JB400×S, motor model: Y-180L-8.

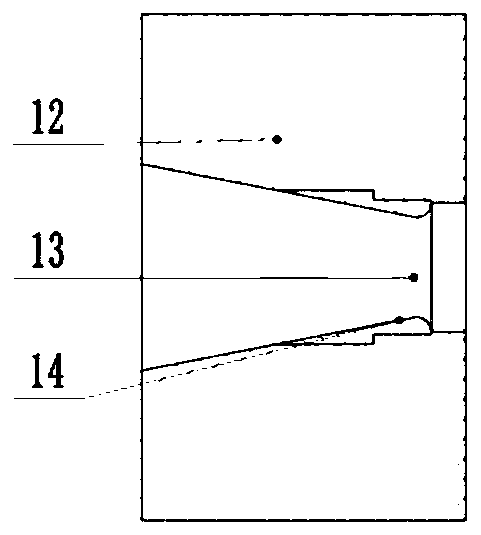

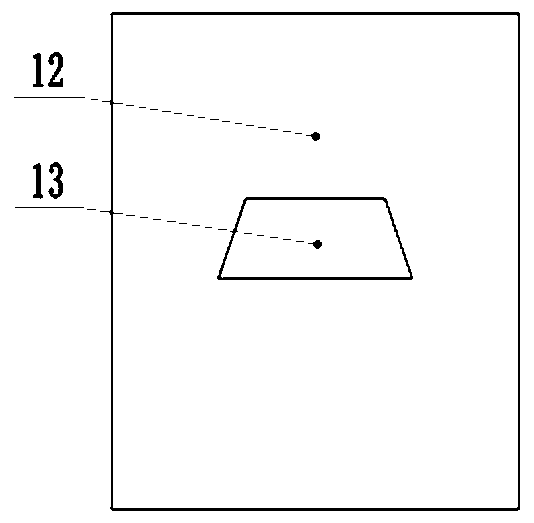

[0039]The positioning and calibration mechanism includes a calibration plate 6. The bottom of the calibration plate 6 is fixedly connected to the inner bottom of the housing 1 through screws. The upper end...

Embodiment 2

[0048] Embodiment two is basically as attached Figure 4 As shown, the difference between the second embodiment and the first embodiment lies in the reel 2 and the base 3, the upper end of the base 3 is provided with a groove for accommodating the reel 2, the reel 2 is hollow inside, the right side is open, and the left side is open. The side is closed, and arc-shaped magnetic strips 16 matching the shape of the inner wall of the reel 2 are respectively bonded to the opening on the right side, and the polarities of the upper and lower arc-shaped magnetic strips 16 are opposite, and the left side of the reel 2 The coaxial fixedly is connected with rotating shaft 15, and rotating shaft 15 passes the left side wall of reel 2 and is connected with the left side wall of base 3 grooves rotatably, on the groove right side wall, is fixedly connected with fixed rod 18 by screw, fixed rod 18 Extend from the right side of the reel 2 into the inside of the reel 2, such as Figure 5 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com