Accurate continuous bending method of U-shaped large forging

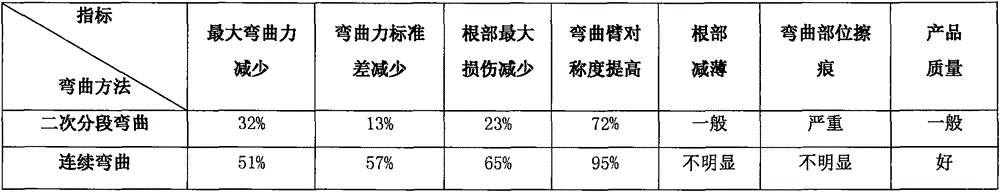

A technology for large forgings and forgings, applied in the field of precise continuous bending, can solve the problems of sudden change in forming load, poor symmetry of forgings, excessive scratches in the contact area between forgings and dies, etc., to reduce the bending load, improve the symmetry of forgings, and improve the processing process. smooth smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to illustrate the technical process of the present invention more clearly, the forging of the coupler frame of a railway freight car is used as an example forging below, and the present invention is further described in detail in conjunction with the accompanying drawings. What needs to be specially explained here is that the coupler frame is an important part for a railway freight car, and is a typical U-shaped frame structure, which is particularly suitable for the implementation of the present invention.

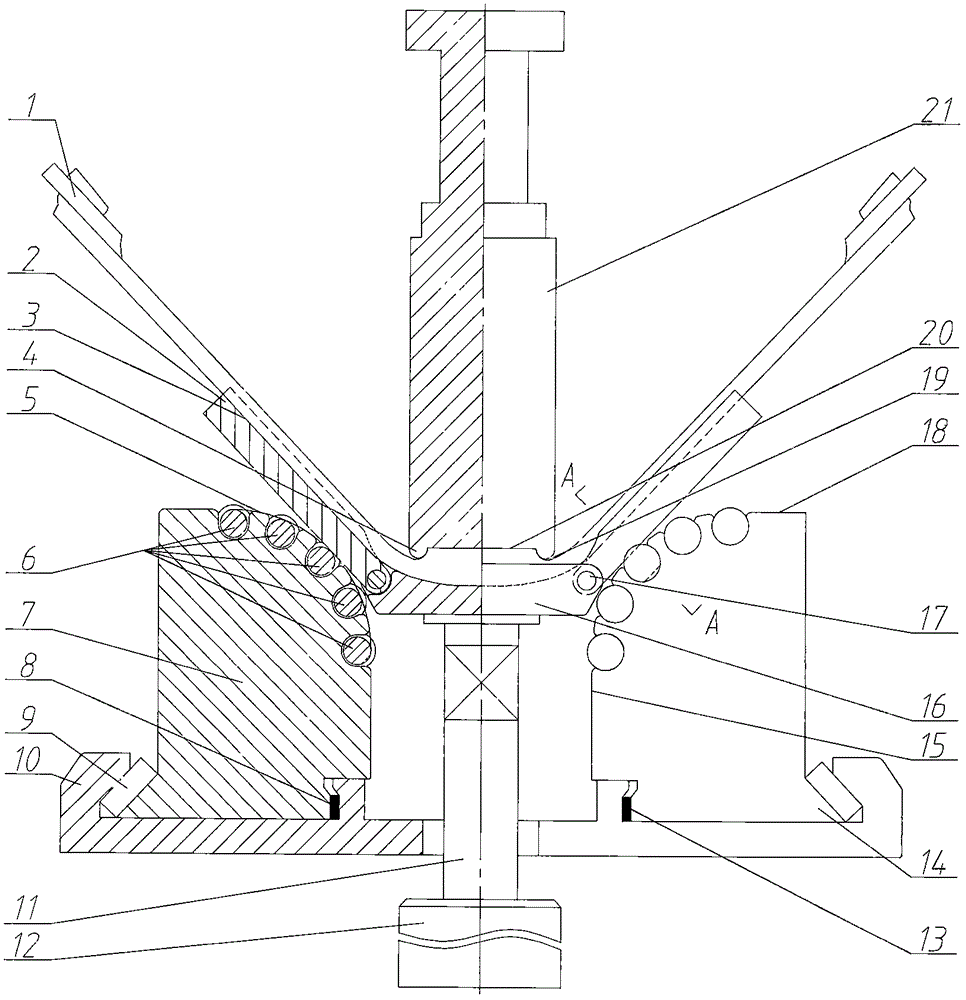

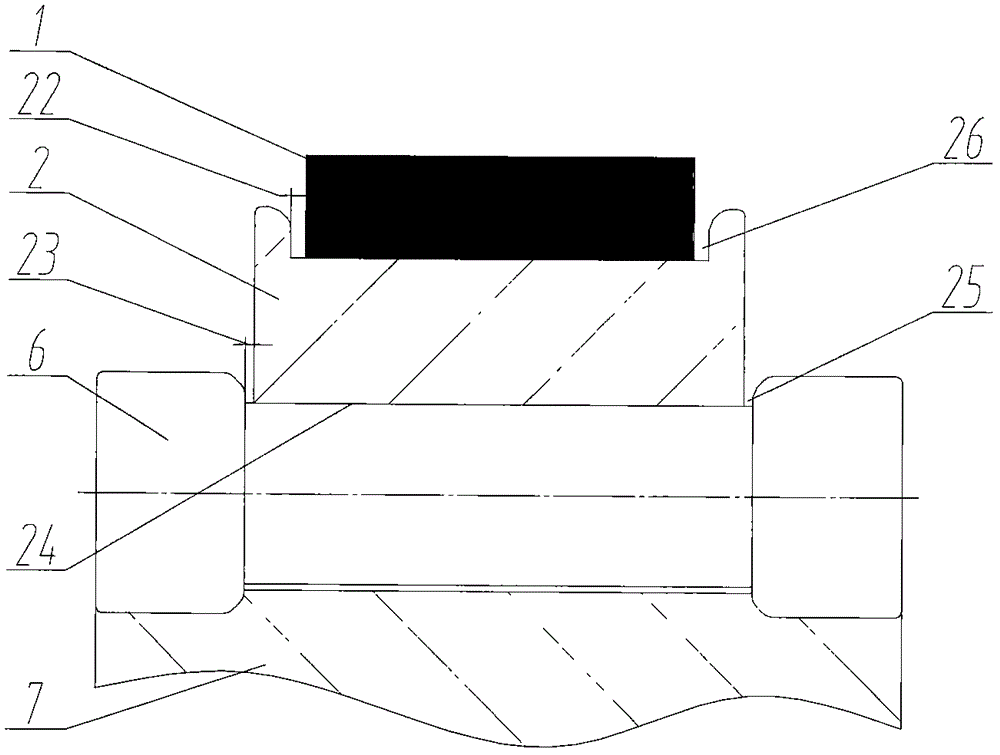

[0027] When this method is implemented, the figure 1 , figure 2 The structural device shown in the figure realizes the bending and forming of the railway wagon coupler frame forging 1, and its structure includes an arc-shaped entrance die 7, and a matching punch 21 and a back pressure die 26 with a bending guide plate 2 are realized, wherein , the working surface 5 of the arc-shaped entrance die 7 in contact with the bending guide plate 2 is 1 / 4 of a com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com