Inhibitor for preventing the formation of natural gas hydrates of high-sulfur acid gas fields

A technology of natural gas and hydrate, which is applied in the direction of chemical change-inhibiting composition, gas fuel, gas/liquid distribution and storage, etc. It can solve the problems of large influence of gas composition and poor inhibition effect, so as to reduce equipment investment and improve Preventive effect, convenient transportation and on-site use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

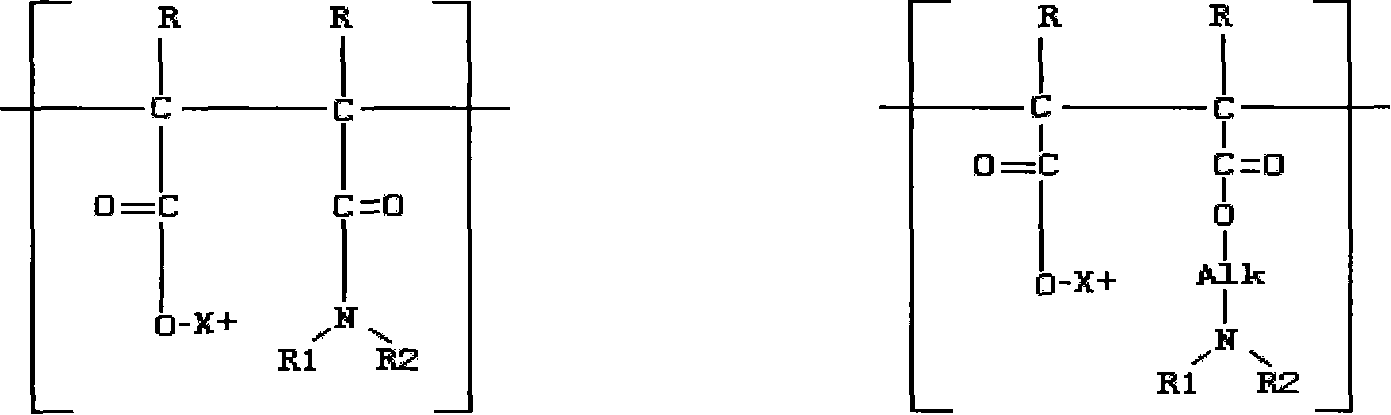

Method used

Image

Examples

Embodiment 1

[0029] 1), Raw material formula:

[0030] Terpolymer of vinylpyrrolidone / vinylcaprolactam / N,N-dimethylaminoethyl methacrylate: 20%;

[0031] Polyamide ester polymerized from maleic anhydride and alkanolamine: 10%;

[0032] Ethylene glycol butyl ether: 10%;

[0033] Polyoxyethylene alkyl alcohol ether (JFC): 3%

[0034] Imidazoline water-soluble corrosion inhibitor: 5%

[0035] Methanol: 12%;

[0036] Ethylene glycol: 39.95%;

[0037] Silicone defoamer: 0.05%;

[0038] 2), operating conditions:

[0039] Add the above raw materials into the reaction kettle, mix and stir for 30 minutes at a temperature of about 35°C to obtain a light yellow viscous liquid product.

Embodiment 2

[0041] 1), Raw material formula:

[0042] Vinylpyrrolidone / vinylcaprolactam binary copolymer (50% effective content): 20%;

[0043] Amidation modified product of maleic anhydride polymer: 15%;

[0044] Ethylene glycol butyl ether: 5%;

[0045] Polyoxyethylene alkylphenol ether (OP-10): 3%;

[0046] Imidazoline water-soluble corrosion inhibitor: 5%

[0047] Ethanol: 12%;

[0048] Ethylene glycol: 39.95%

[0049] Silicone defoamer: 0.05%

[0050] 2), operating conditions:

[0051] Add the above raw materials into the reaction kettle, mix and stir for 30 minutes at a temperature of about 35°C to obtain a light yellow viscous liquid product.

Embodiment 3

[0053] The hydrate inhibitor product of the present invention has been field tested for nearly four months in two winters on a certain high-sulfur moisture transmission pipeline of PetroChina that has not taken heat preservation measures, and has achieved good field application effects. Due to the high content of hydrogen sulfide acid gas in the pipeline natural gas, the hydrate formation temperature is relatively high. In winter when the temperature is low, hydrate blockage often occurs in the separator and valve of the gathering pipeline and the downstream well station. On average, every 3 to 5 days must be Pig the ball once. In order to ensure the normal production of gas wells and pipelines, an average of 45Kg of ethylene glycol antifreeze must be injected intermittently every day; Hydrate blockage did not occur, production and operation were normal, and the pigging cycle could be extended to 15-20 days.

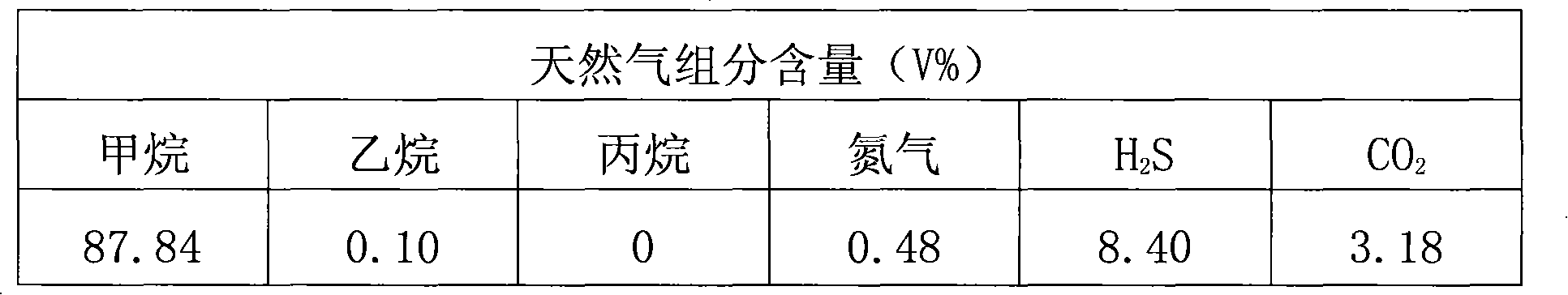

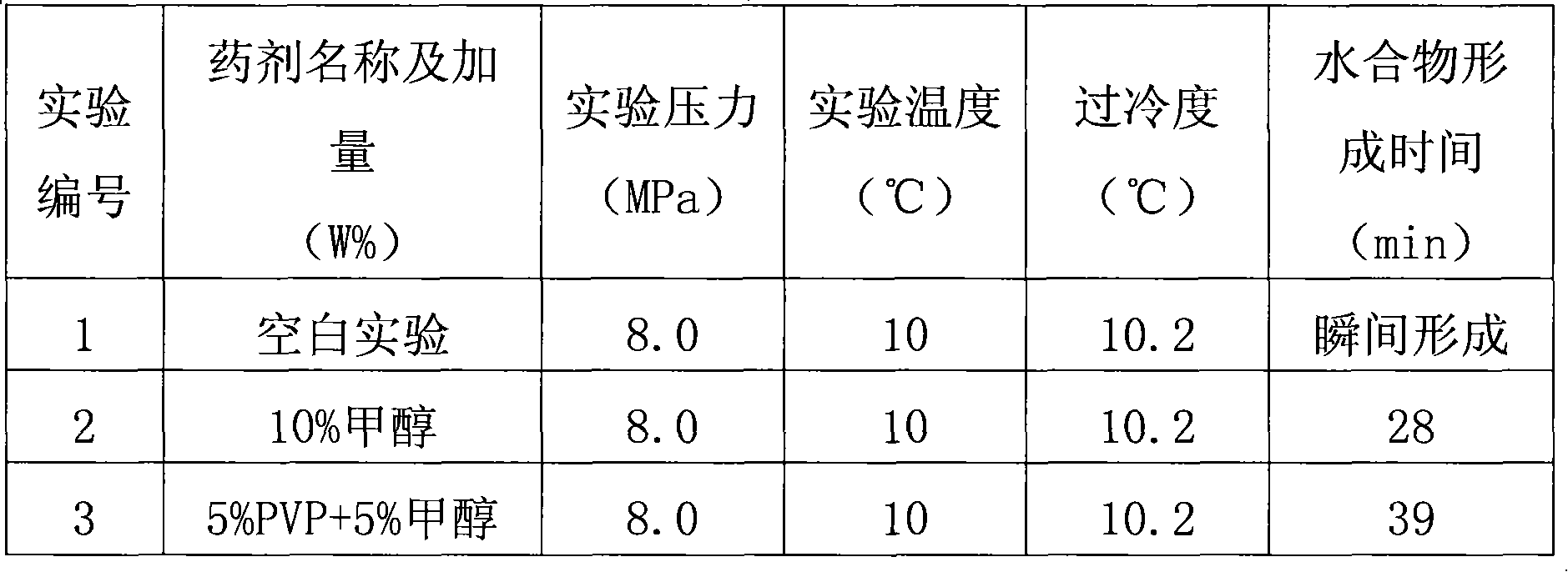

[0054] The natural gas composition and gathering and transportatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com