Sulfur-containing natural gas hydrate inhibitor

A technology of hydrate inhibitor and natural gas, which is applied in drilling composition, gas/liquid distribution and storage, pipeline system, etc., can solve problems such as hydrate blockage, and achieve the effect of good inhibition effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

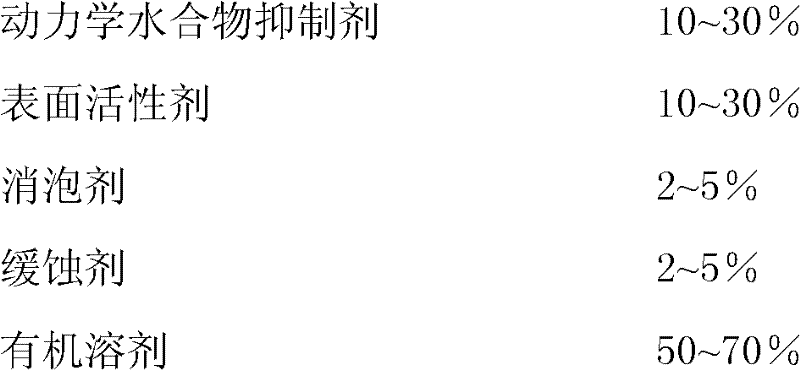

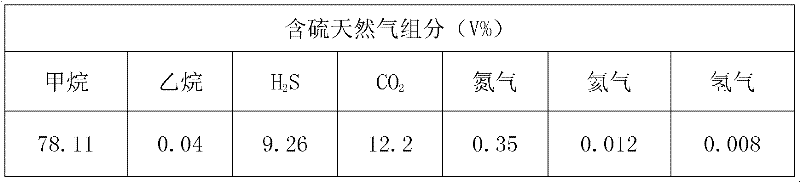

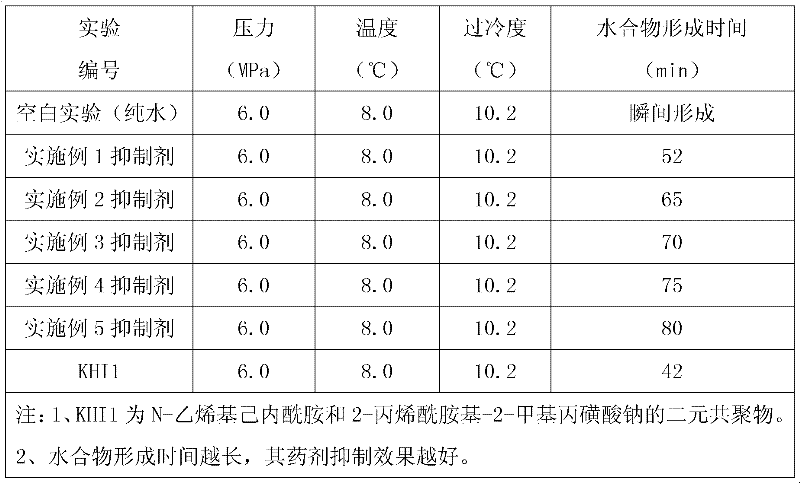

[0022] The selected sulfur-containing natural gas hydrate inhibitor consists of: kinetic inhibitor (a binary copolymer of N-vinyl caprolactam and 2-acrylamido-2-methylpropanesulfonate sodium) accounts for 10%, surfactant Ethylene glycol monobutyl ether accounts for 30%, defoamer isobutanol accounts for 2%, corrosion inhibitor imidazoline quaternary ammonium salt accounts for 2%, and organic solvent ethylene glycol accounts for 56%. The cloud point of the inhibitor is 78° C. (a sample with a concentration of 1% by mass is dissolved in saline with a concentration of 1% by mass). The experimental conditions and results are shown in Table 2.

Embodiment 2

[0024] The selected sulfur-containing natural gas hydrate inhibitor consists of: kinetic inhibitor (a binary copolymer of N-vinyl caprolactam and 2-acrylamido-2-methylpropanesulfonate sodium) accounts for 30%, surfactant Ethylene glycol monobutyl ether accounts for 30%, defoamer isobutanol accounts for 2%, corrosion inhibitor imidazoline quaternary ammonium salt accounts for 2%, and organic solvent ethylene glycol accounts for 36%. The cloud point is 82° C. (a sample with a concentration of 1% by mass is dissolved in brine with a concentration of 1% by mass). The experimental conditions and results are shown in Table 2.

Embodiment 3

[0026] The selected sulfur-containing natural gas hydrate inhibitor consists of: kinetic inhibitor (a binary copolymer of N-vinyl caprolactam and 2-acrylamido-2-methylpropanesulfonate sodium) accounts for 30%, surfactant Ethylene glycol monobutyl ether accounts for 30%, defoamer isobutanol accounts for 2%, corrosion inhibitor imidazoline quaternary ammonium salt accounts for 2%, and organic solvent methanol accounts for 36%. The cloud point is 80° C. (a sample with a concentration of 1% by mass is dissolved in brine with a concentration of 1% by mass). The experimental conditions and results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com