Suppressing vibration method for marine riser vortex-induced vibration and suppressing vibration apparatus thereof

A vortex-induced vibration and riser technology, which is applied in the directions of support devices, drill pipes, casings, etc., can solve the problems of large effective cross-section in the incoming flow direction, adhesion of marine sediments, and large amount of materials, so as to achieve difficult adhesion of marine sediments. , Reduce the project cost, reduce the effect of vortex-induced vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

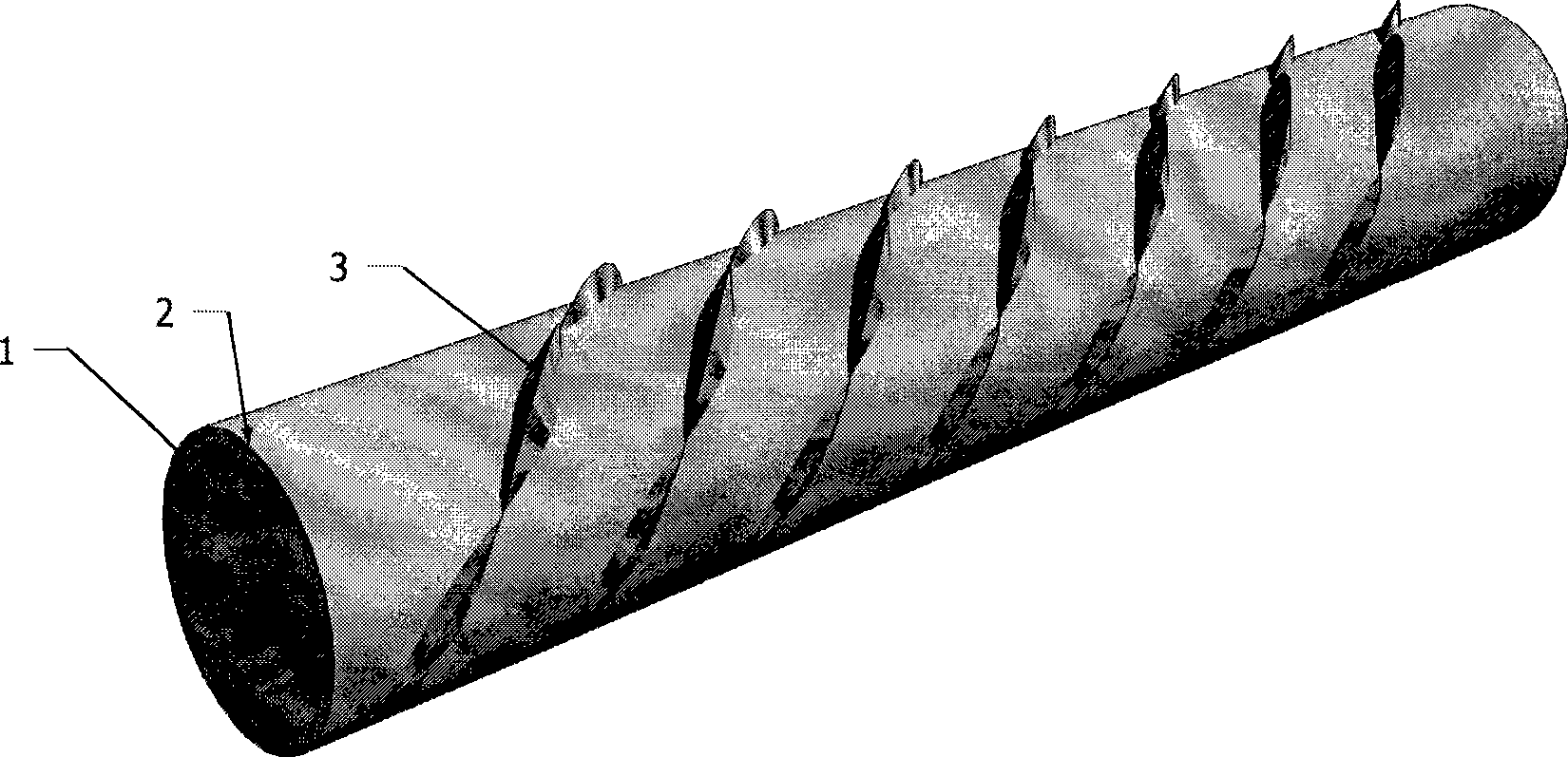

[0027] Such as figure 1 , A spiral spoiler rib layout: the outer diameter of the riser D=1m, and the spiral position is marked on the outer surface of the deflector 2 with a pitch of 5m. The length Y of the spoiler rib 4 is 0.5 meters, the thickness Z of the middle part of the rib bottom is 0.3 meters, and the rib height H is 0.3 meters. Install the spoiler ribs on the riser along the spiral position, and the distance between two adjacent spoiler ribs is 5 meters.

Embodiment 2

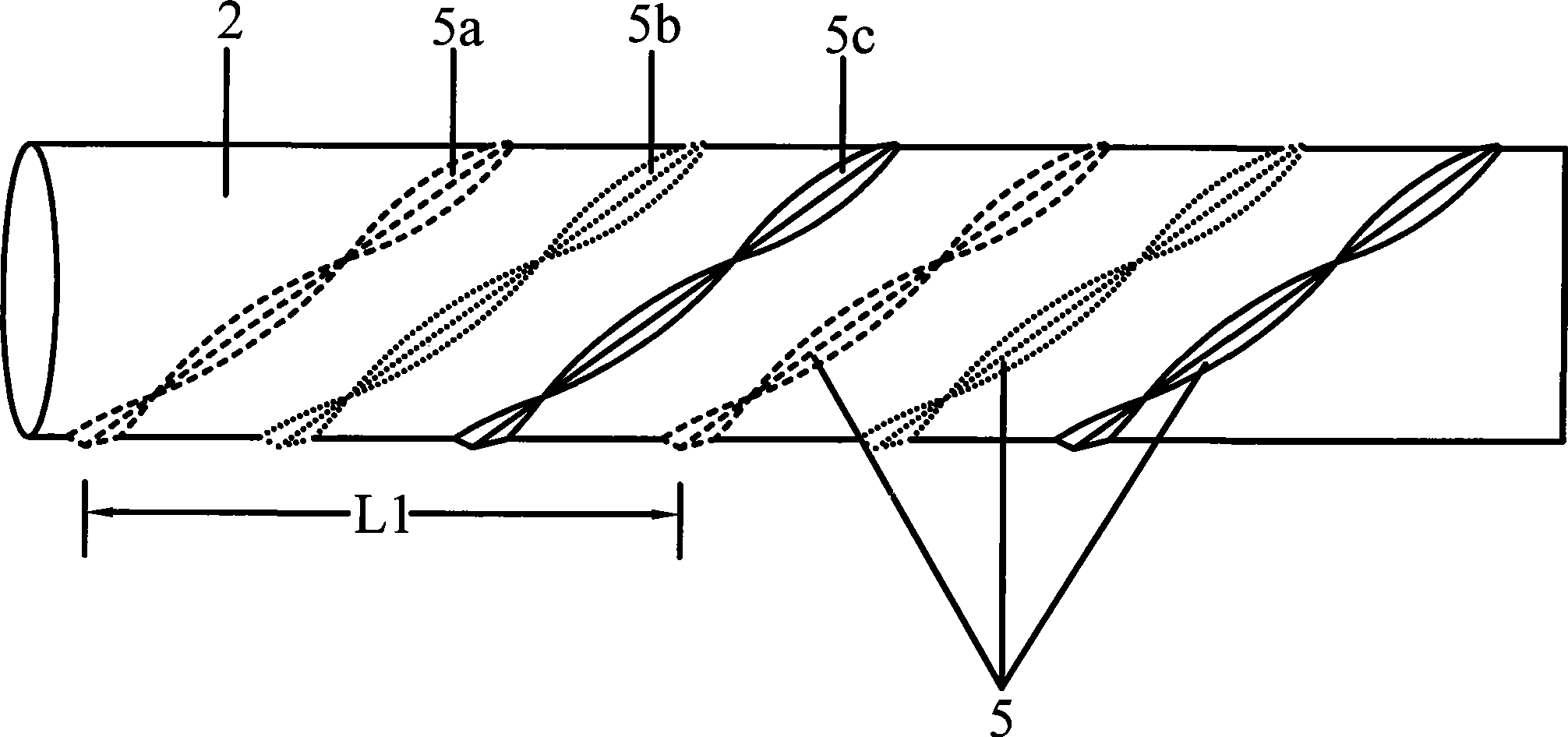

[0029] Such as figure 2 , In the form of three spiral spoiler ribs: the outer diameter of the riser D=1m, the spiral position is marked on the outer surface of the deflector 2 according to the pitch L1 of 5m, which is the arrangement position of the first spoiler rib 5a ; Based on the first spiral, the second spiral is wound in parallel with the first spiral at a distance of 1.67 meters. This is the location of the second spoiler rib 5b; and then the second spiral As a benchmark, the third spiral is wound in parallel with the second spiral at a distance of 1.67 meters, which is the location of the third spoiler rib 5c. The length Y of the spoiler ribs 5a, 5b, and 5c is 0.5 meters, the thickness Z of the middle part of the rib bottom is 0.3 meters, and the rib height H is 0.3 meters. The three spoiler ribs are simultaneously wound along the spiral position and fixedly installed on the riser. The distance between two adjacent spoiler ribs is 1.67 meters in a pitch L1.

Embodiment 3

[0031] Such as figure 2 , In the form of three spiral spoiler ribs: the outer diameter of the riser D=1m, the spiral position is marked on the outer surface of the deflector 2 according to the pitch L1 of 9m, which is the arrangement position of the first spoiler rib 5a ; Based on the first spiral, the second spiral is wound in parallel with the first spiral at a distance of 3.0 meters. This is the location of the second spoiler rib 5b; and then the second spiral As a benchmark, the third spiral is wound in parallel with the second spiral at a distance of 3.0 meters. This is the arrangement position of the third spoiler rib 5c; the length Y of the spoiler ribs 5a, 5b, and 5c are all 0.5 M, the thickness Z of the middle part of the rib bottom is 0.3 m, and the height H of the rib is 0.3 m. Three spoiler ribs are installed on the riser along the spiral line at the same time, and the distance between two adjacent spoiler ribs is 3.0 meters within a pitch of L1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com