Bird nest-like structure aluminum oxide as well as preparation method and application thereof

A technology of alumina and ultra-fine alumina, which is applied in chemical instruments and methods, structural parts, aluminum compounds, etc., can solve the problems of reducing the heat transfer efficiency of materials, affecting the thermal conductivity of composite materials, and increasing the quality of materials, so as to improve The effect of mechanical properties, light weight and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Discussion on the Morphology of Raw Materials and the Solid Content of Aluminum Oxide Dispersion

[0034] In order to explore the influence of different shapes of alumina raw materials and the solid content of the prepared alumina dispersion on the preparation of bird's nest-like alumina, the present invention uses spherical ultrafine alumina and commercially available non-spherical alumina as raw materials to prepare alumina-like Alumina with bird's nest structure, see Example 1-1 to Example 1-10 for specific experiments.

Embodiment 1-1

[0036]A method for preparing aluminum oxide with a bird's nest structure, the specific steps are:

[0037] (1) Add spherical ultrafine alumina with a particle size of 30 to 150nm into water, stir and disperse evenly at a stirring speed of 500rpm to obtain a dispersion liquid. The spherical ultrafine alumina is prepared by plasma technology, spherical The phase of ultrafine alumina is a mixed phase of unstable phase θ-alumina and γ-alumina;

[0038] (2) The dispersion liquid obtained in step (1) is subjected to 10min static settlement treatment, after the static sedimentation finishes, remove the sediment, collect the upper layer suspension, and obtain the alumina dispersion liquid; the solid content of the alumina dispersion liquid is 20wt% ;

[0039] (3) The alumina dispersion obtained in step (2) is sprayed and granulated by a spray granulation dryer to obtain particle agglomerates. The specific process parameters of spray granulation are: the inlet temperature is 270°C, th...

Embodiment 1-2

[0041] The content of Example 1-2 is basically the same as that of Example 1-1, except that the solid content of the alumina dispersion prepared in step (2) is 30 wt%.

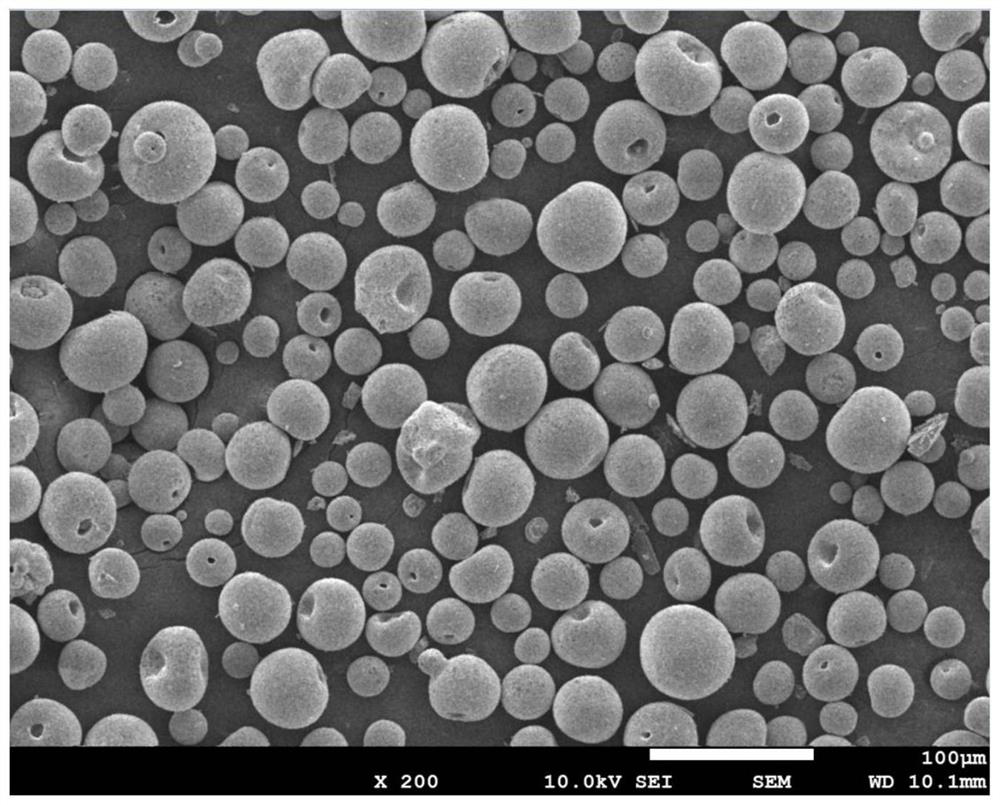

[0042] The scanning electron micrograph of the class bird's nest structure aluminum oxide that the present embodiment prepares is as follows figure 1 shown. Depend on figure 1 It can be seen that the morphology of the bird's nest-like structure alumina prepared in this example is a hollow sphere, the particle size of the hollow sphere is 20-70 μm, and there is a large hole sunken inward on the hollow sphere, and the pore size of the large hole is 3-10 μm , the surface of the hollow sphere is covered with small holes, and the diameter of the small holes is 30-200nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com