Steel scrap preheater and preheating method of electric-arc furnace step disturbance culvert

A preheating device and electric arc furnace technology, applied in the field of metallurgy, can solve problems such as unfavorable workshops, heavy maintenance affecting production, and serious dynamic sealing air leakage, etc., so as to improve the reliability and safety of equipment and eliminate gaps being blocked Possibility, the effect of reducing investment cost of transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

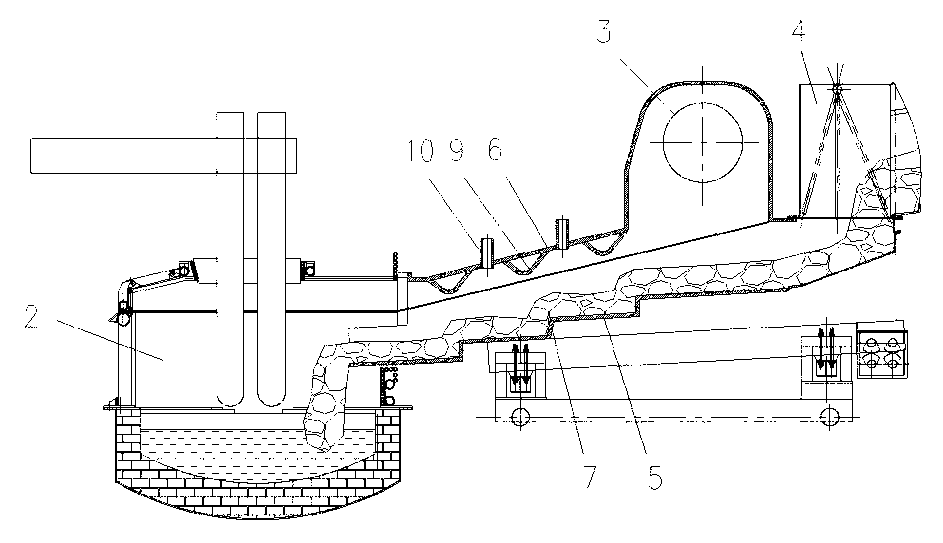

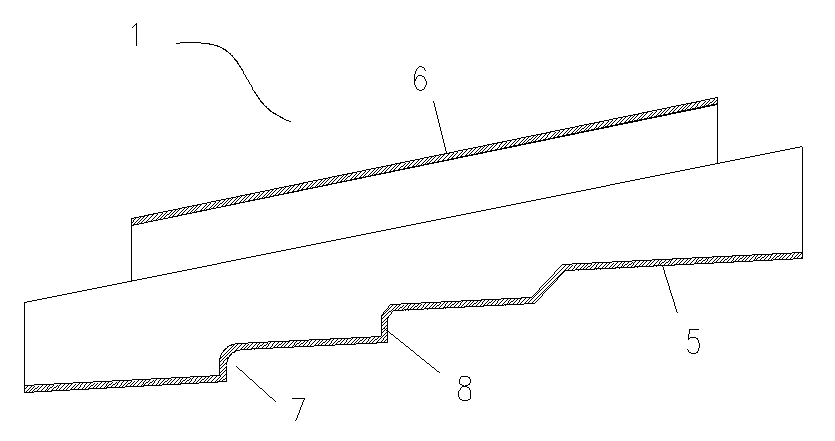

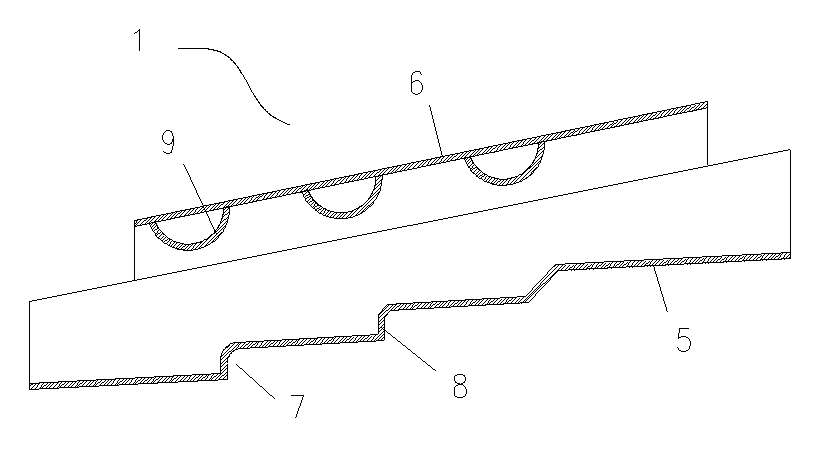

[0029] Such as figure 1 As shown, it is a structural schematic diagram of an embodiment of the electric arc furnace step disturbance channel scrap preheating device of the present invention. The electric arc furnace step disturbance channel scrap steel preheating device in this embodiment includes a heat exchange channel 1 installed obliquely and used to transport scrap materials. The low side end of the heat exchange channel 1 is connected to the electric furnace 2, and the high side end is respectively connected to The smoke collection and dust removal pipe 3 is connected to the feeding sealing device 4, and the heat exchange channel 1 includes a feeding trough 5 for conveying scrap steel materials to the electric furnace 2 and a cover mounted on the feeding trough 5 and used for flue gas diversion 6, and the heat exchange channel 1 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com