Drying system for plastic foam particle film

A drying system and plastic foam technology, which is applied in the field of plastic foam particle-coated drying system, can solve the problems of unguaranteed production quality, inability to collude with hot spots, and large heat energy consumption, etc., to achieve particle quality assurance and drying effect Good, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

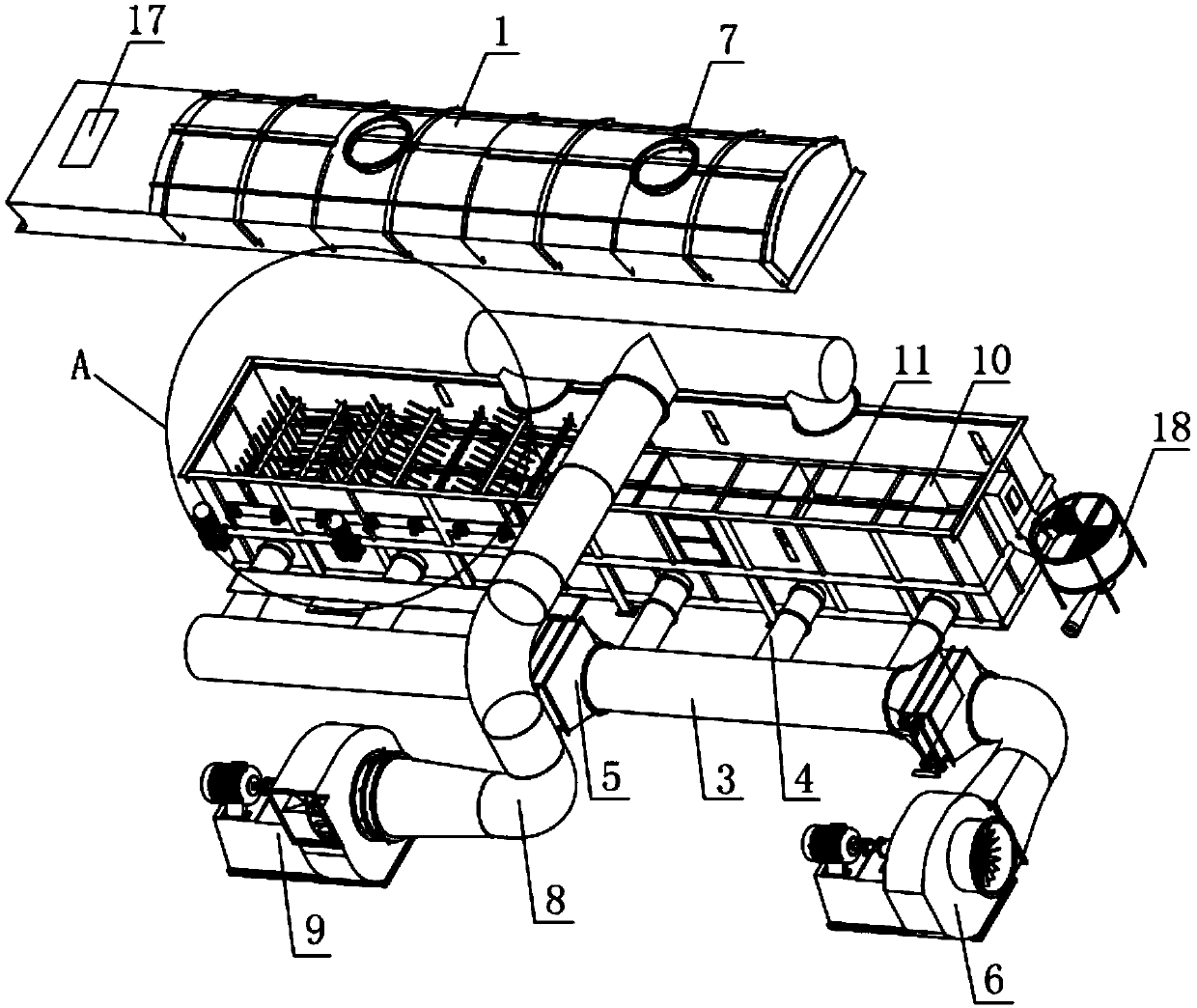

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

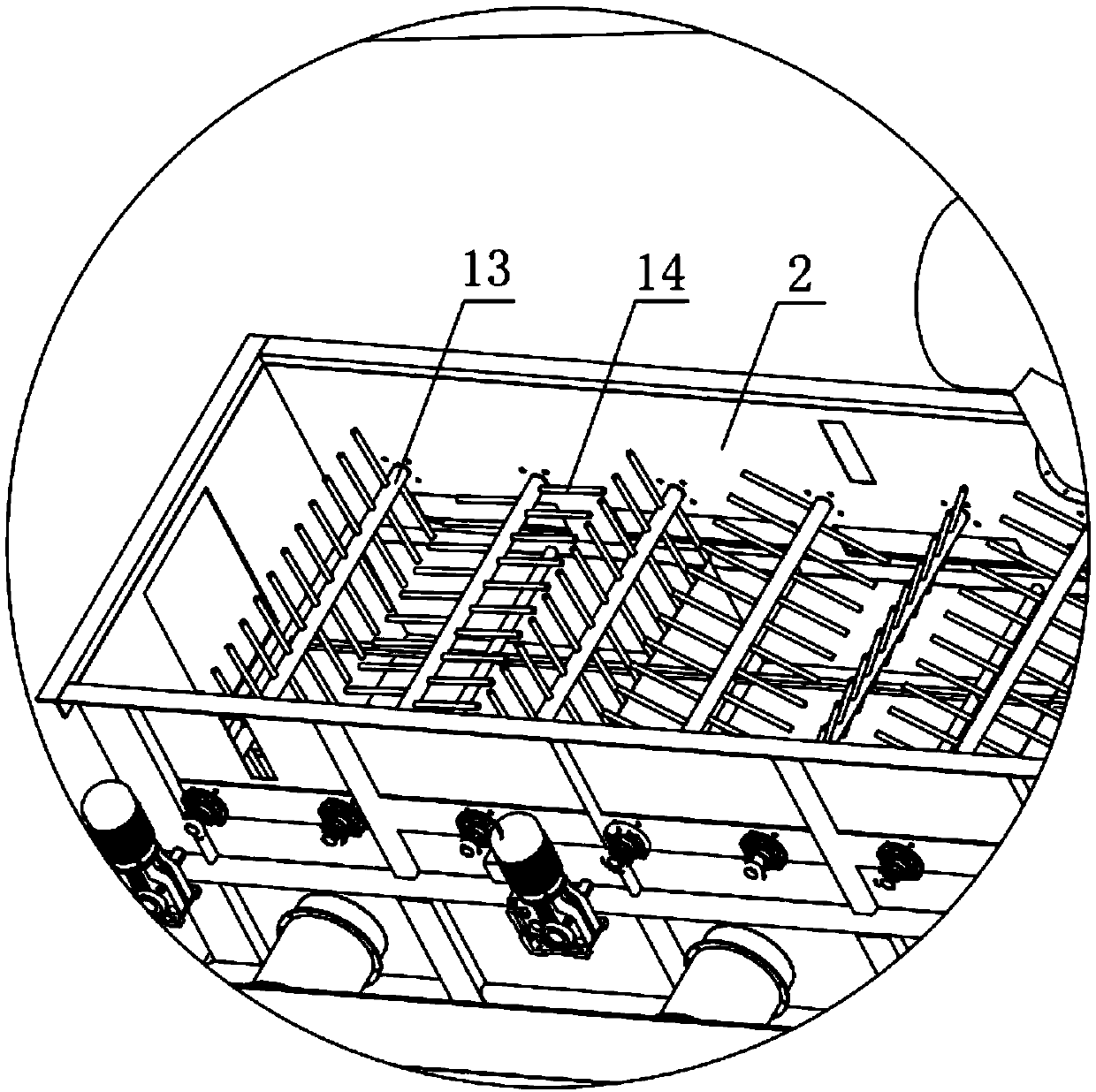

[0020] like figure 1 , 2 , Shown in 3, a kind of drying system that is used for plastic foam granule coating, comprises the drying cavity 2 that forms a sealed cavity with top cover 1 and top cover and is provided with in drying cavity 2 The device also includes an air inlet device connected to the lower part of one side of the drying chamber 2 to keep the particles in the drying chamber in a suspended state, and an air exhaust device that forms an air circulation with the air inlet device for comprehensive and rapid drying.

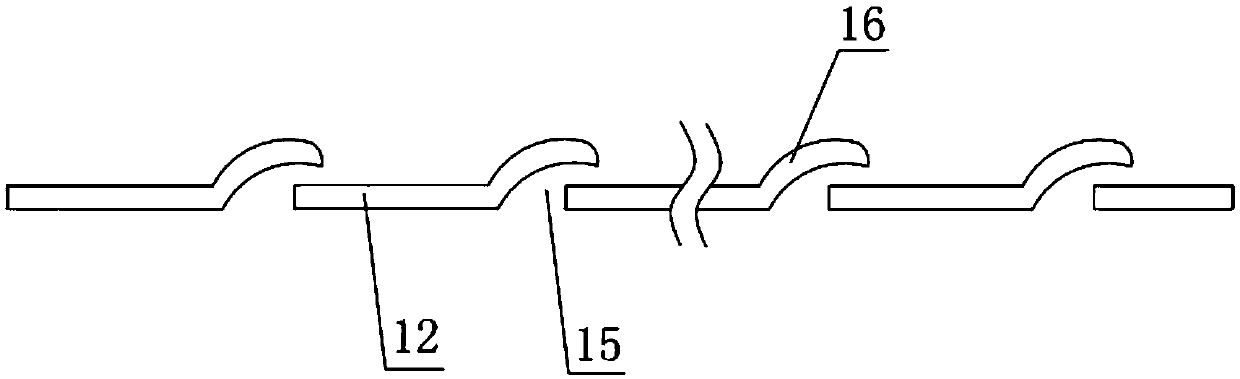

[0021] The air inlet device comprises a plurality of air inlet pipes 4 arranged in series through the air blast duct 3, and the air blast pipe 3 is provided with a radiator 5 for providing heat to assist drying for the drying cavity, and the series arrangement of the air inlet pipe 4 can be Realize heat energy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com