Coal slime rubbing-kneading equipment

A technology of coal slime and equipment, which is applied in the field of coal slime rubbing and equipment to achieve good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

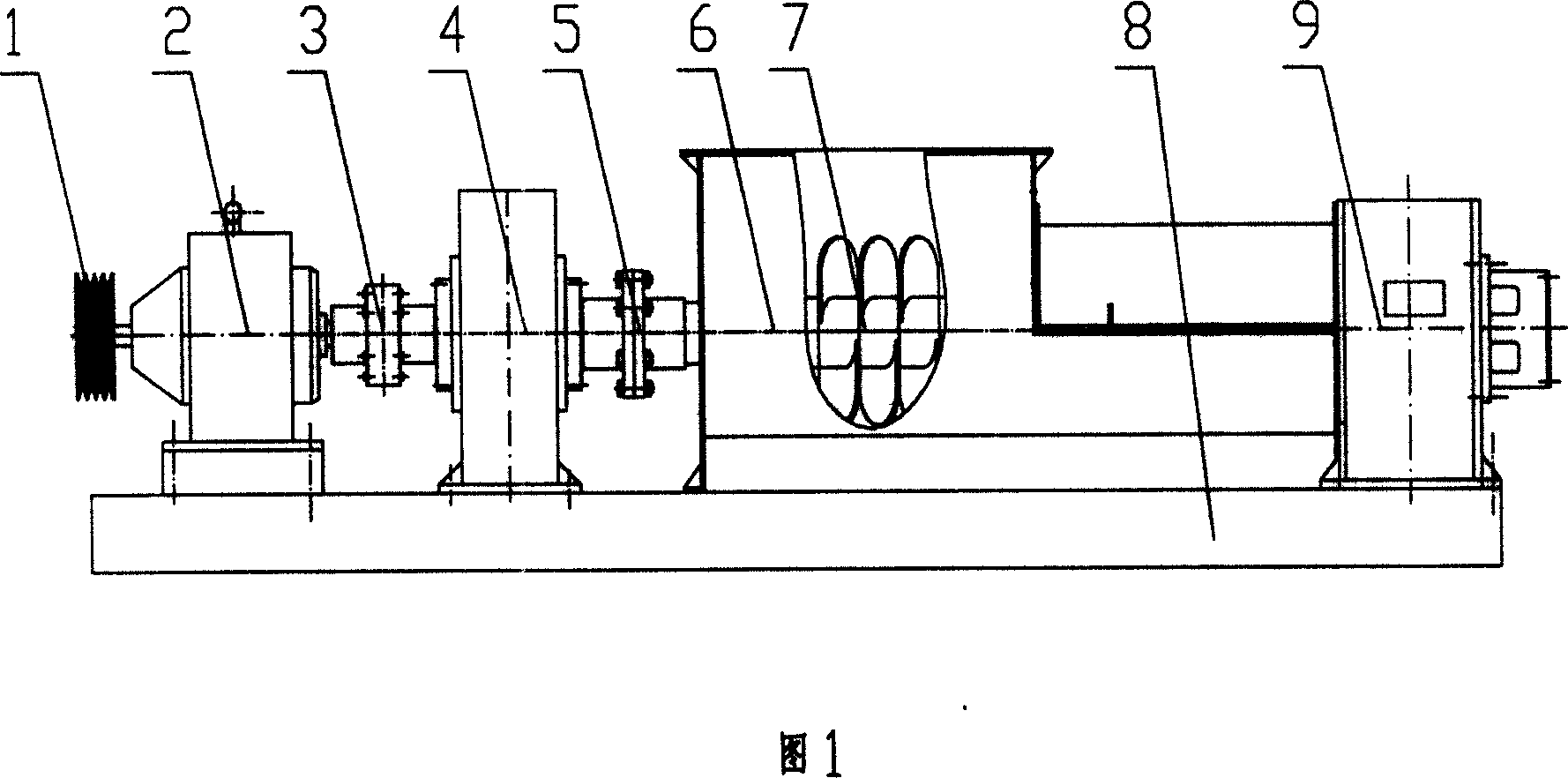

[0045]Please refer to Fig. 1-shown in Fig. 5, a kind of coal slime rubbing equipment of preferred embodiment of the present invention, it mainly comprises motor, speed reducer 2, gear box 4, feed bin 6, discharge hopper 9, rotating shaft 7 , Coupling 5.

[0046] As shown in FIG. 1 , the motor, the reducer 2 , the gear box 4 , the feed bin 6 and the discharge hopper 9 are installed on the underframe 8 . It is transmitted to the reducer 2 through the pulley, the reducer 2 and the gear box 4 are connected together through the coupling 3, and the gear box 4 and the rotating shaft 7 are connected together through the coupling 5.

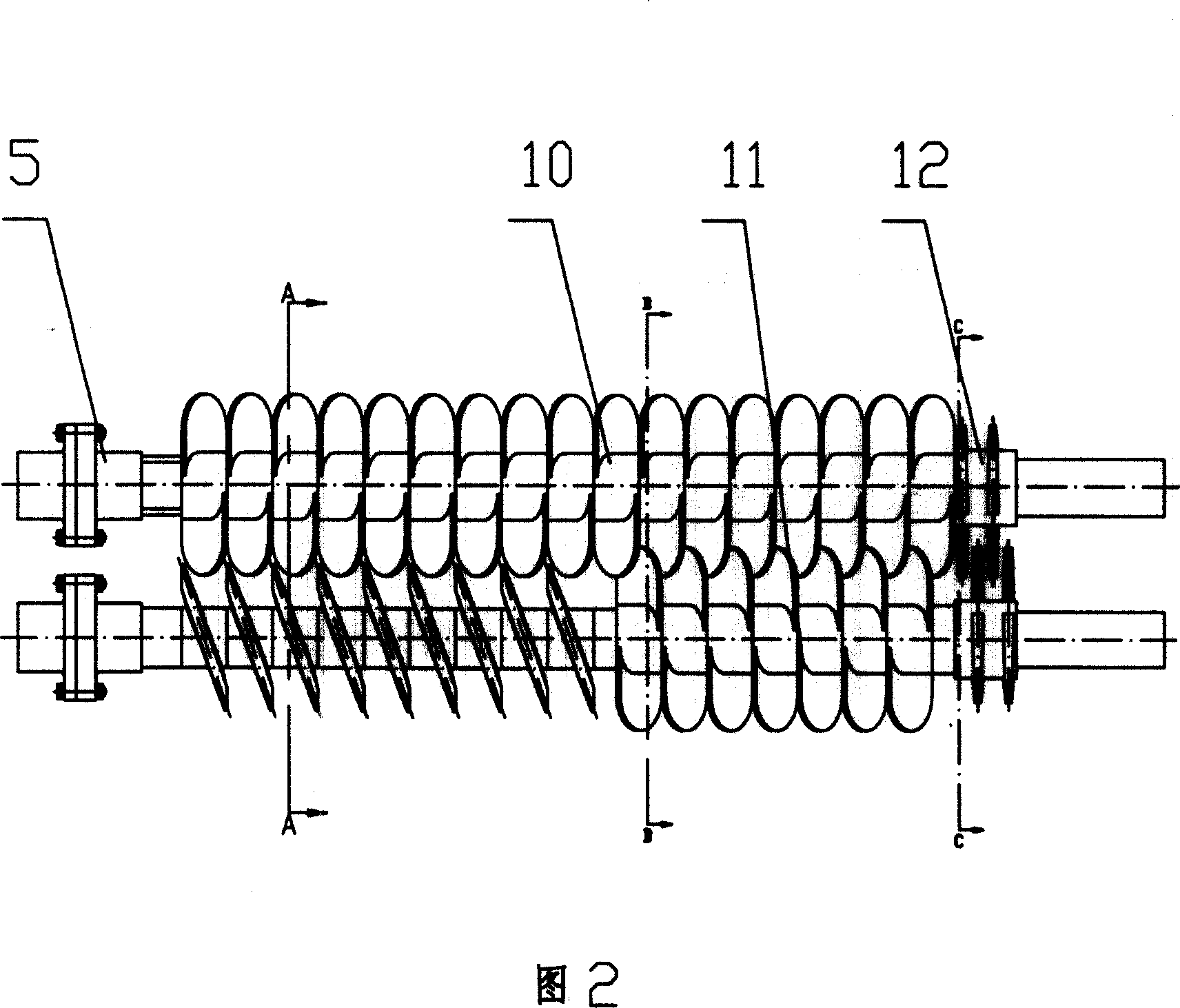

[0047] As shown in Figure 2, a pair of oppositely rotating rotating shafts 7 are equipped with a helical cutting blade and a non-helical cutting reamer blade. The cutting blades are divided into left-handed and right-handed. The cutting blades with the same rotation direction are installed on the same shaft. The end of each rotating shaft 7 and the hoppe...

Embodiment 2

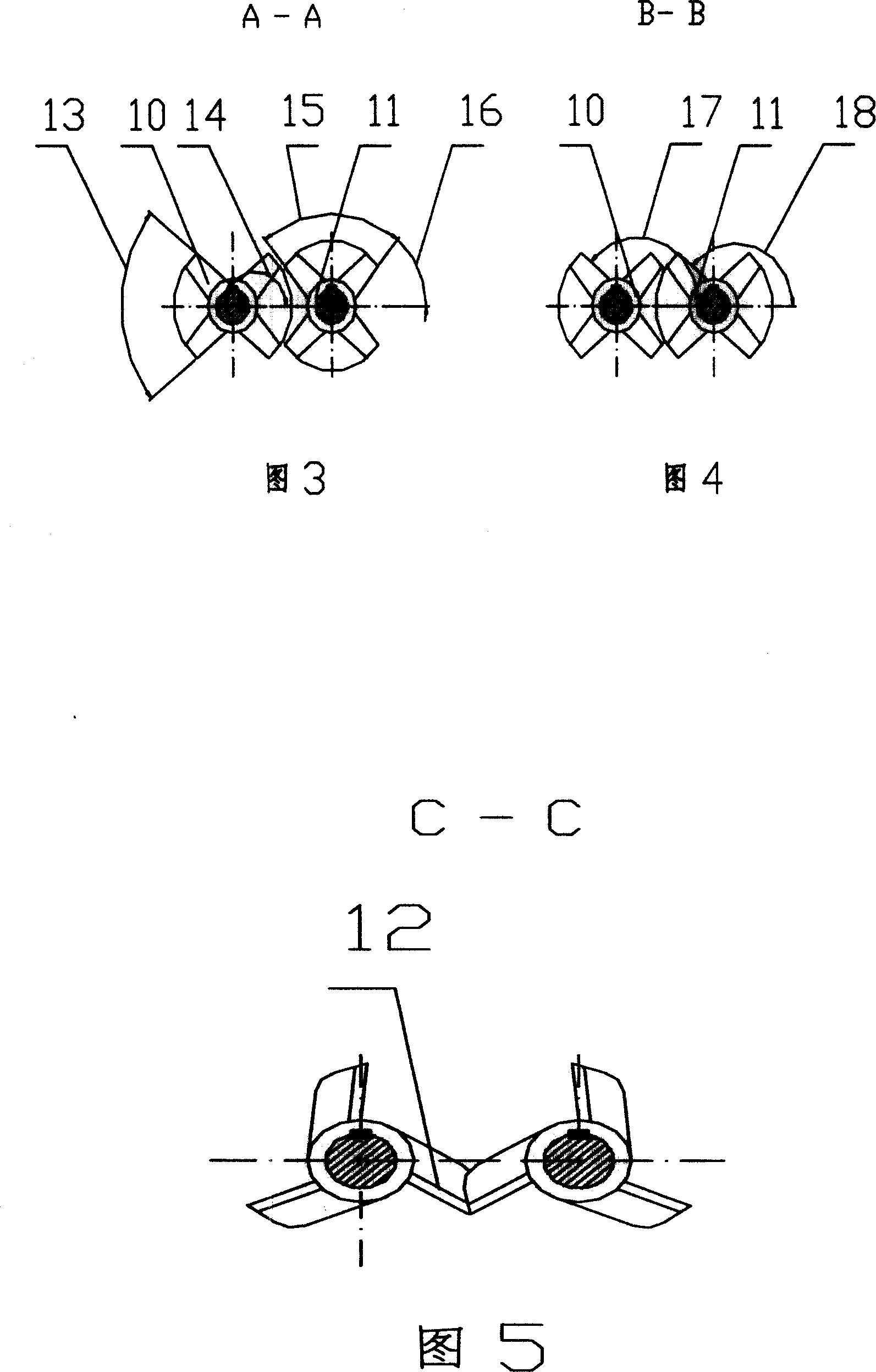

[0052] A coal slime kneading equipment according to a preferred embodiment of the present invention, the spiral cutting blade is fan-shaped when viewed in the axial direction, and the fan-shaped angle 13 and the fan-shaped angle 15 are each 75°. The phase angle 14 of the left-handed cutting blade 10 and the phase angle 16 of the right-handed cutting blade 11 differ by 80°, the phase angle 14 is 120°, the phase angle 16 is 40°, and the phase angle 17 and the phase angle 18 are equal to 120° °, 120 power sources adopt hydraulic motors, and other structures are the same as in Embodiment 1

Embodiment 3

[0054] A kind of coal slime kneading equipment of preferred embodiment of the present invention, described helical cutting blade is viewed as fan-shaped along axial direction, and fan-shaped angle 13 and fan-shaped angle 15 are each 100 °, and the phase angle 14 of left-handed cutting blade 10 and right-handed The phase angle difference of the phase angle 16 of the rotary cutting blade 11 is 100°, the phase angle 14 is 150°, the phase angle 16 is 50°, the phase angle 17 and the phase angle 18 are equal to 150°, the power source adopts a hydraulic motor, other structures Same as Example 1

[0055] The working principle of the present invention is that after dehydration, the coal slime enters the crushing device from the feed bin 6, and is first crushed through the area shown in Figure 3. The large coal slime is cut by the spiral cutting blade, and at the same time, it is cut along the axis direction under the action of the spiral surface. , move from the feed port to the 9 end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com