Making method and system of alum-free vermicelli

A preparation system and technology of vermicelli, applied in the field of preparation of alum-free vermicelli, can solve the problems of uneven drying, reduced work efficiency, high labor intensity of staff, etc., and achieve the advantages of ensuring taste and toughness, improving work efficiency and saving labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: The present invention will be further described in detail through the embodiments in conjunction with the accompanying drawings.

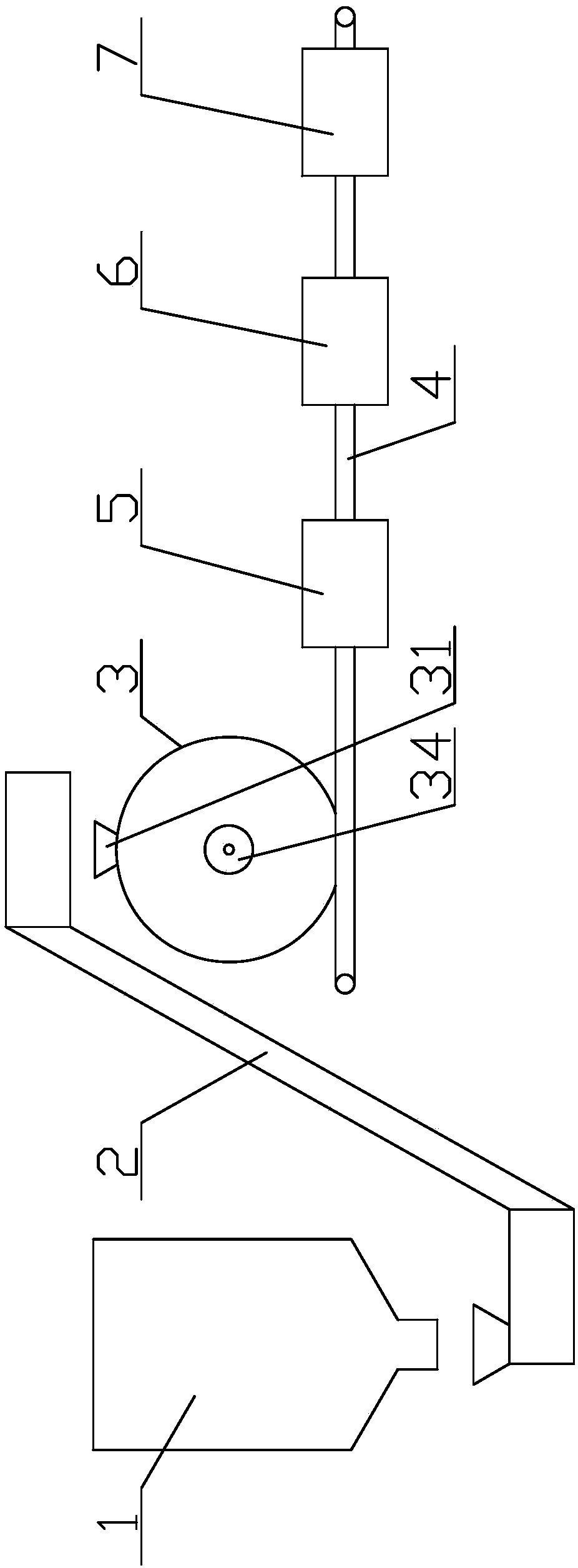

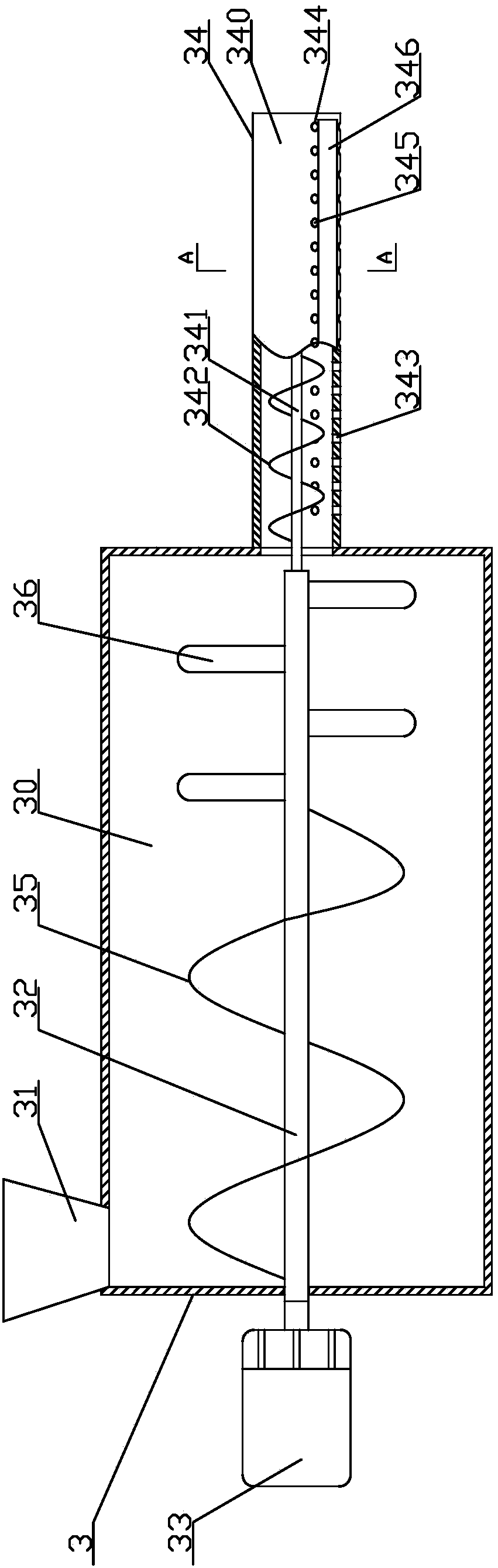

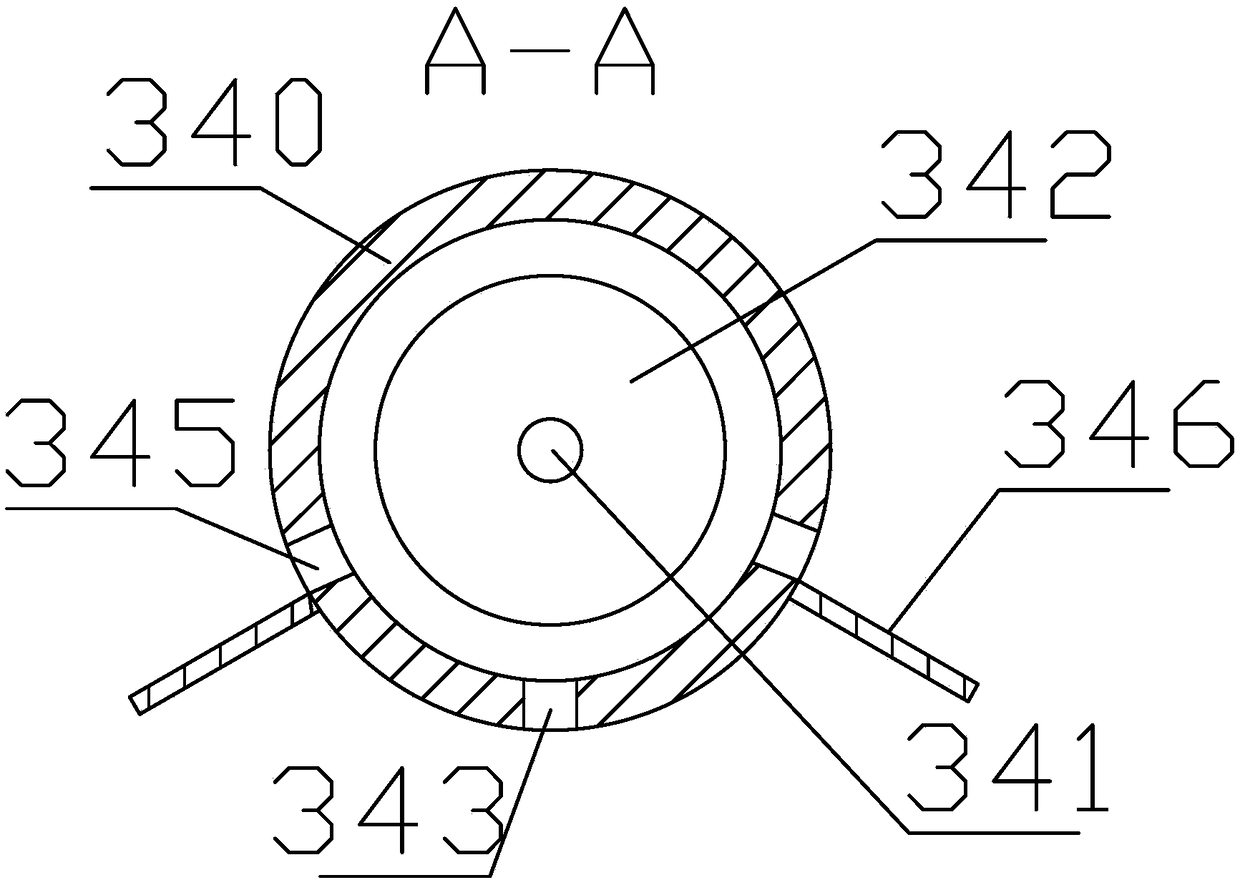

[0027] Such as Figure 1 to Figure 3 Shown, the preparation system of alum-free vermicelli, it comprises the agitator 1 that connects successively, feeder 2, extruder 3 and conveyor belt 4; Pool 7; the electromagnetic wave heating device includes a housing, the inner wall of the housing is provided with a number of electromagnetic heating tubes along the length direction, the two ends of the housing are respectively provided with a material inlet and a material outlet, and the conveyor belt is penetrated by the material inlet and passed through by the material outlet. out. Extrusion molding machine 3 comprises the mixing drum 30 that horizontally arranges, stirring shaft 32, motor 33, extrusion mold 34, helical blade 35 and stirring bar 36; One end is placed on the outside of the mixing drum 30, and is coaxially fixedly conne...

Embodiment 2

[0032] Embodiment 2: the preparation method of vermicelli without alum, utilize the preparation system of vermicelli without alum in embodiment 1 to prepare vermicelli without alum, it comprises the following steps: (1) noodle making; (2) extrusion molding; (3) pregelatinization (4) gelatinization by electromagnetic wave heating; (5) cooling; wherein,

[0033] (1) Noodle making: Pour a certain amount of starch into the mixer 1, then add 40% water of the starch mass, the water temperature is required to be controlled above 83°C, and the starch is stirred until it becomes loose and flocculent to obtain flocculent starch;

[0034] (2) Extrusion molding: After cooling the flocculent starch to 20°C, add it to the extrusion molding machine 3 and extrude to obtain prefabricated vermicelli; wherein, the molding pressure is 6 bar, and the motor speed is 180 rpm.

[0035] (3) pre-gelatinization: put the pre-gelatinized vermicelli into the pre-gelatinization boiling water pool 5 and boil...

Embodiment 3

[0038] Embodiment 3: the preparation method of no alum vermicelli, utilize the preparation system of embodiment 1 no alum vermicelli to prepare no alum vermicelli, it comprises the following steps: (1) noodle making; (2) extrusion molding; (3) pregelatinization (4) gelatinization by electromagnetic wave heating; (5) cooling; wherein,

[0039] (1) Noodle making: Pour a certain amount of starch into mixer 1, then add water with 65% of the starch mass, the water temperature is required to be controlled above 83°C, and the starch is stirred until it becomes loose and flocculent to obtain flocculent starch;

[0040] (2) Extrusion molding: After cooling the flocculent starch to 58°C, add it to the extrusion molding machine 3 and extrude to obtain prefabricated vermicelli; wherein, the molding pressure is 10 bar, and the motor speed is 260 rpm.

[0041] (3) pre-gelatinization: put the formed pre-gelatinized vermicelli into the pre-gelatinization boiling water pool 5 and boil for 3 se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com