Rotary grooving machine with balance device

A balancing device and ditching machine technology, applied in the field of agricultural and forestry machinery, can solve problems such as poor drainage, inability to control the direction of ditch drainage, real-time adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

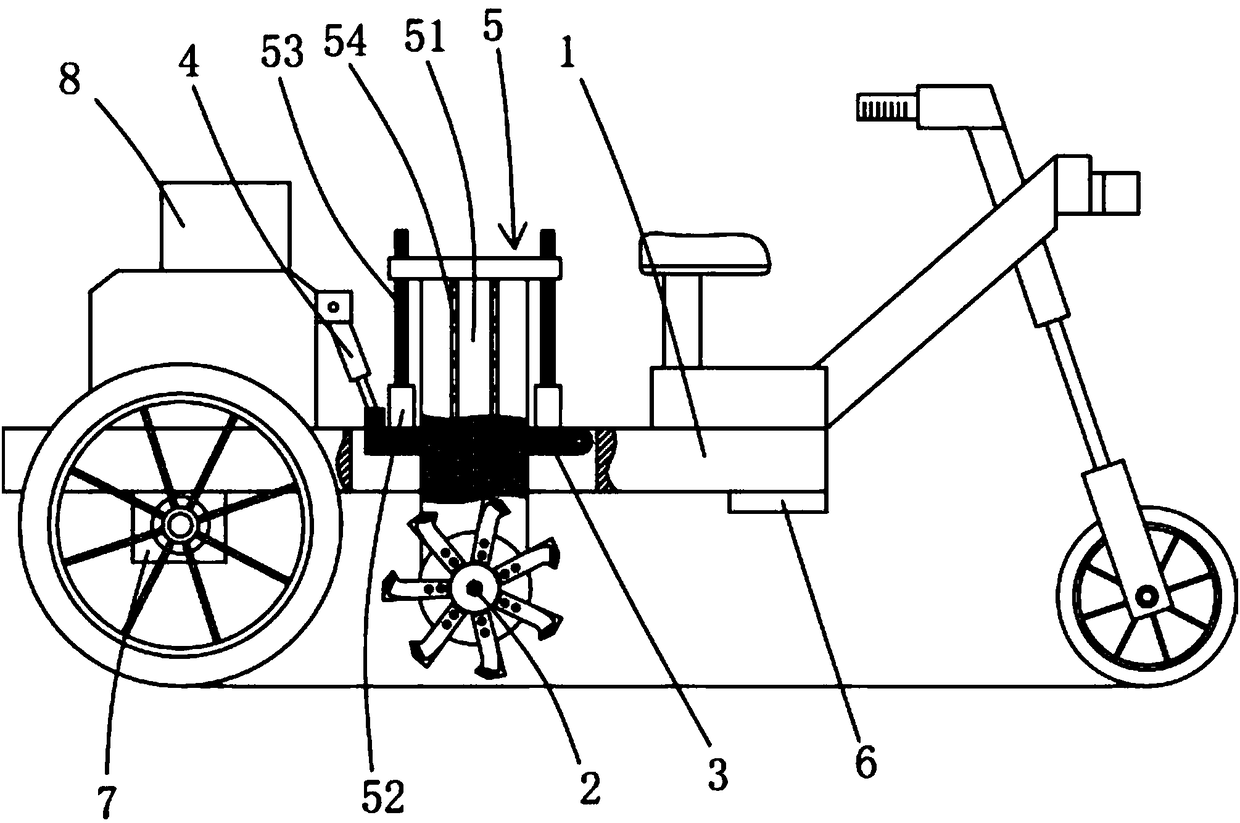

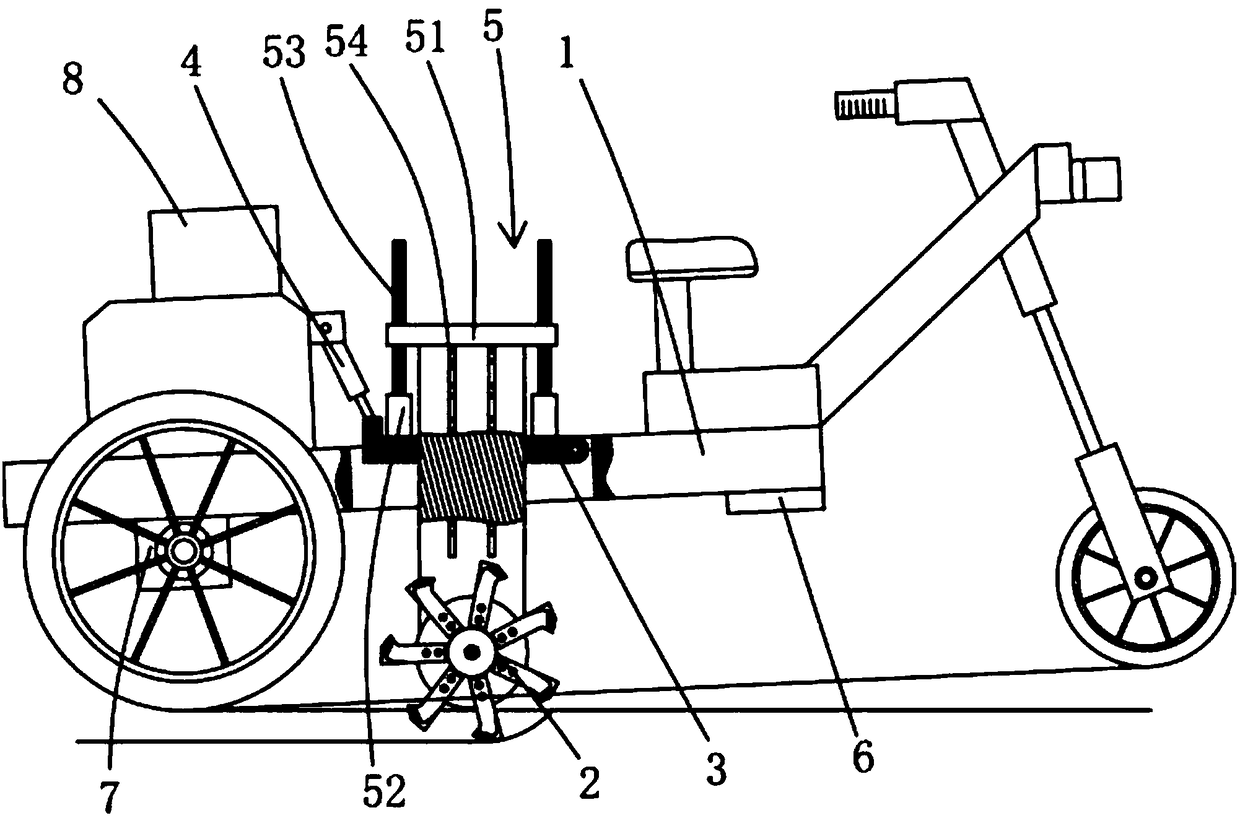

[0014] like figure 1 as shown, figure 1 It is a structural schematic diagram of a rotary ditching machine with a balance device proposed by the present invention; figure 2 It is a structural schematic diagram of a rotary ditching machine with a balance device proposed by the present invention when it is working.

[0015] refer to Figure 1~2 , a rotary ditching machine with a balance device proposed by the present invention, comprising: a body 1, a milling machine 2, a rotating plate 3, a driving device 4, and a control unit, the rotating plate 3 is hinged to the body 1, and the milling machine The planer 2 is installed on the rotating board 3, and the control unit is connected with the driving device 4 for signal, and the driving device 4 drives the rotating board 3 to rotate, and then drives the milling machine 2 to move. During the use of the trencher, the user controls the movement of the driving device 4 through the control unit, so that the rotating plate 3 rotates o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com