Fabricated integral type hollow floor and prefabricated high-rib laminated bottom plate thereof

A hollow floor, integral technology, used in floors, building components, buildings, etc., can solve the problems of unstable connection structure, increased floor weight, waste of raw materials, etc., and achieves excellent sound insulation effect, high bearing capacity, and flat bottom. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

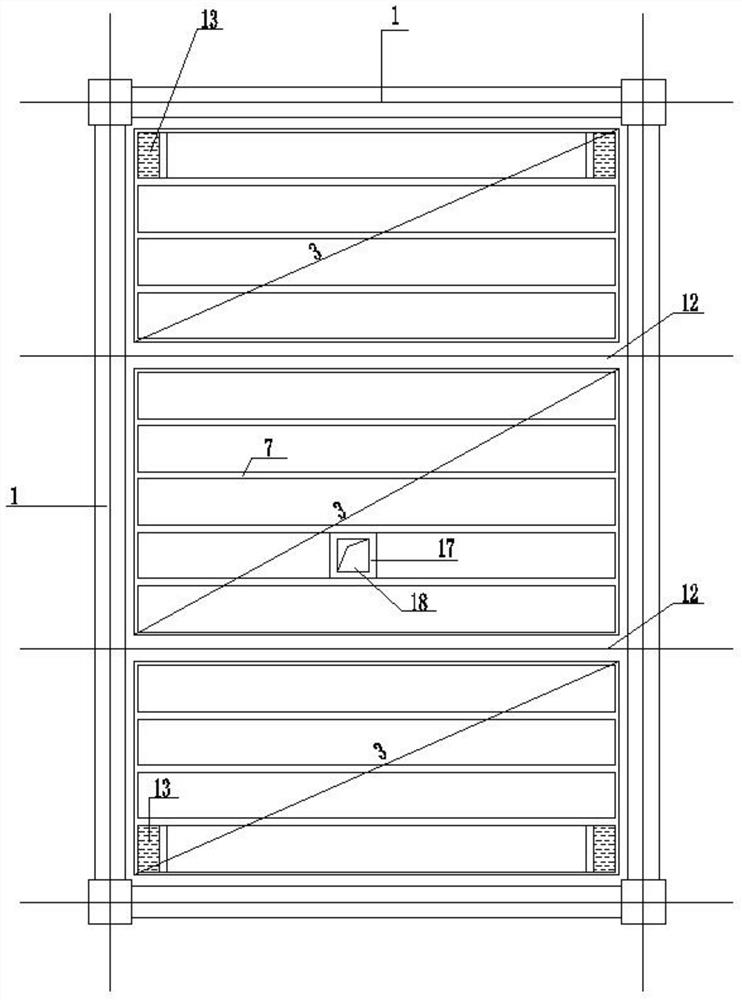

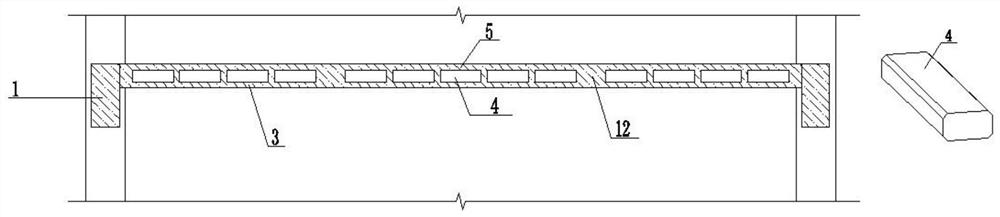

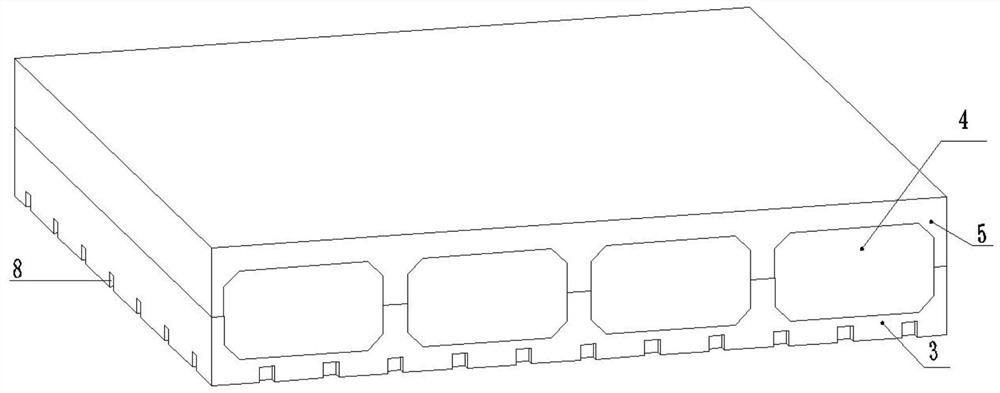

[0047]Please refer to the accompanying drawings of the description, an assembled integral hollow floor, including an assembled integral hollow slab and a laminated frame beam 1, the assembled integral hollow slab includes a prefabricated high-rib laminated bottom slab 3, a built-in filler 4 in the hollow slab, and The laminated layer 5 and the cast-in-place laminated ribs 6 are poured, the prefabricated high-rib laminated floor 3 has upturned ribs 7, and the side of the prefabricated high-rib laminated floor 3 and the upper surface of the upturned ribs 7 are provided with a shear key 8 structure, The upper surface of the upturned rib 7 is provided with truss steel bars or short shear bars 9 and connected with the cast-in-place laminated layer 5 or the cast-in-place laminated rib 6, and the upper surface of the upturned rib 7 is a rough surface; the hollow plate has a built-in filler 4 is a lightweight filler block, a thin-walled component or a formwork that does not need to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com