Process for producing double-sided gambiered Guangdong silk

A production process, the technology of glue, which is applied in the direction of textiles and papermaking, dyeing method, animal fiber, etc., can solve the problems of poor comfort, different internal and external quality, color difference, etc., and achieve comfortable wearing, thick cloth and good hand feeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: a kind of manufacture craft of double-faced black gum silk, comprising the following processing steps,

[0034] 1) Prepare the gray silk; in this step, cut the gray silk into 15-18m / sections, and sew stick cloth heads on both ends of each piece of gray silk.

[0035] 2) Prepare Panicum water; that is, add the crushed Panicum yam to water and stir thoroughly, and the Panicum water obtained after the first filtration is overwater; after the first filtration, add water and stir thoroughly, and then filter it for the second time The water obtained is twice-pass water; after the second filtration, add water and stir thoroughly, and the water obtained after the third filtration is three-pass water. For example: after taking 200 jin of yams, crushing them, adding 200 jins of water and stirring them thoroughly, the 180 jins of yam water obtained by filtering is the overwater. Then add 200 jin of water into the above-mentioned filtered overcooked yam, then fully f...

Embodiment 2

[0053]Embodiment 2: The characteristics of this embodiment are that in the process steps of embodiment 1, in step 8), every time the front side of the gray silk is soaked and dried twice or three times, the bottom surface of the gray silk is soaked and dried once, so Cycle three or four times. In this step, while the front side of the gray silk is soaked, the bottom surface of the gray silk is soaked at intervals to prepare for the process step of making the reverse side in advance, which can enhance the adhesion of the butterscotch layer formed by the water on the reverse side of the gray silk . All the other are with embodiment 1. Just can get the silk weaving product that both sides all have black colloidal substance. The color depth of the black colloidal substance can be adjusted through the concentration of scorch water or the number of times of immersion.

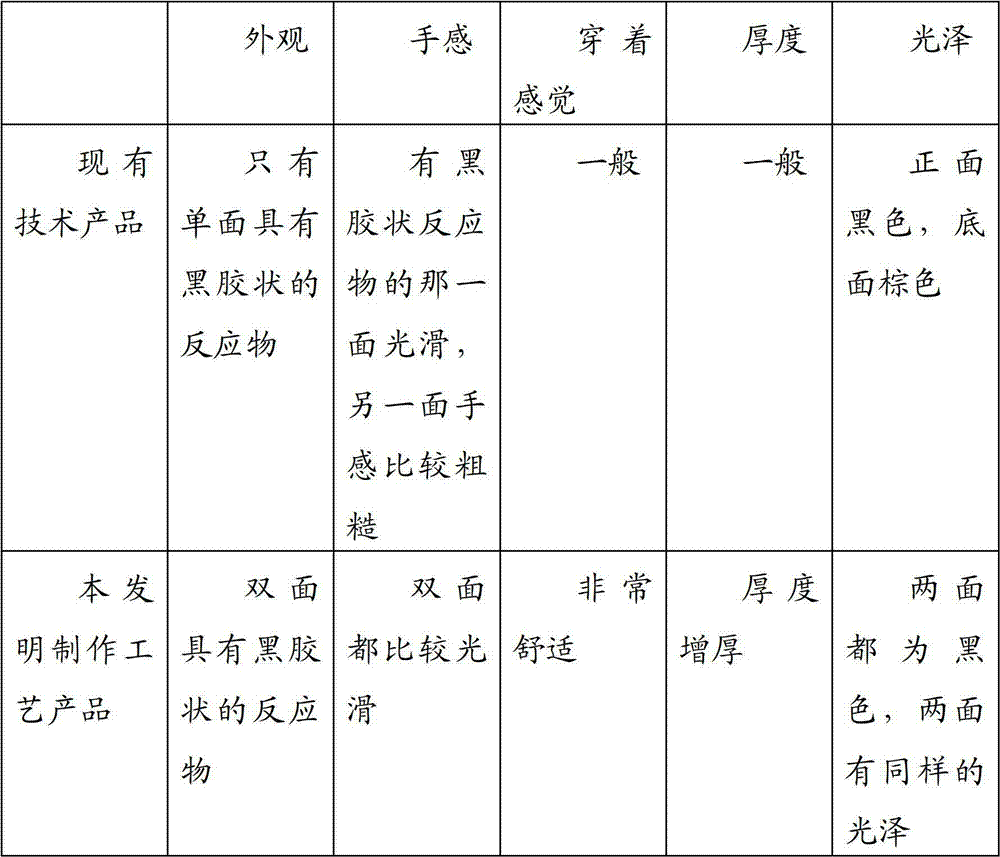

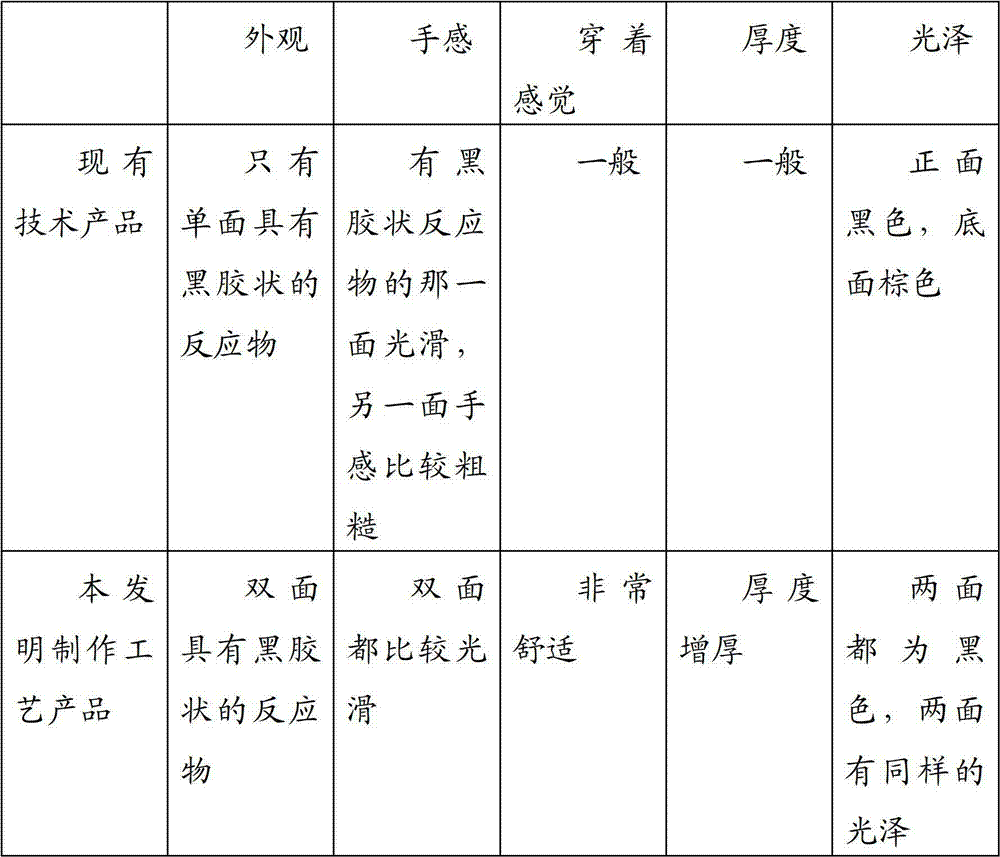

[0054] The products obtained by the manufacturing process of the present invention and the product comparison t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com