Laser preparation method for microchannels of microfluidic chip

A microfluidic chip and microchannel technology, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve the problems of large pressure difference, limited fluid flow rate, and poor practicability, etc. Achieve the effect of flat bottom surface and small surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

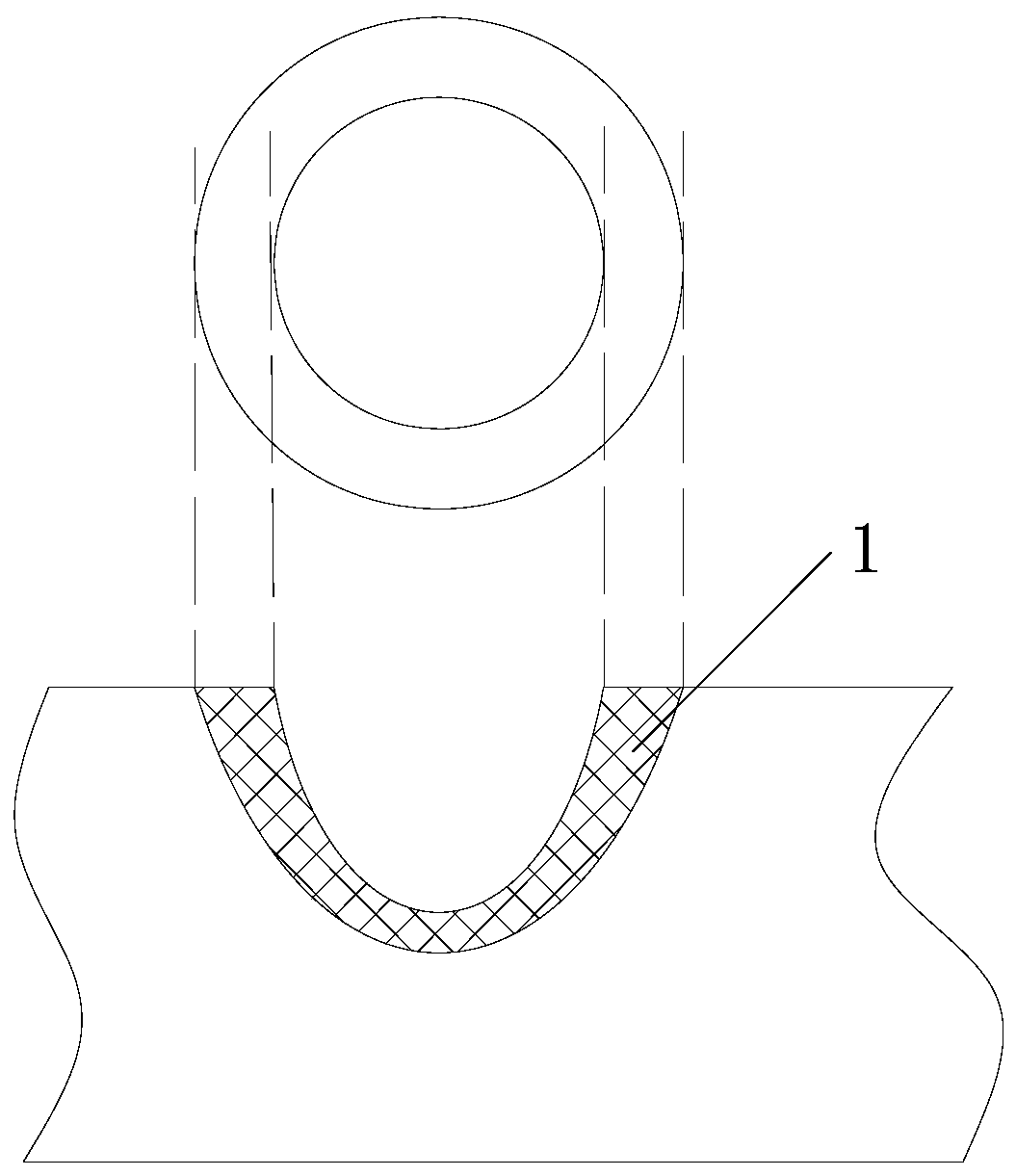

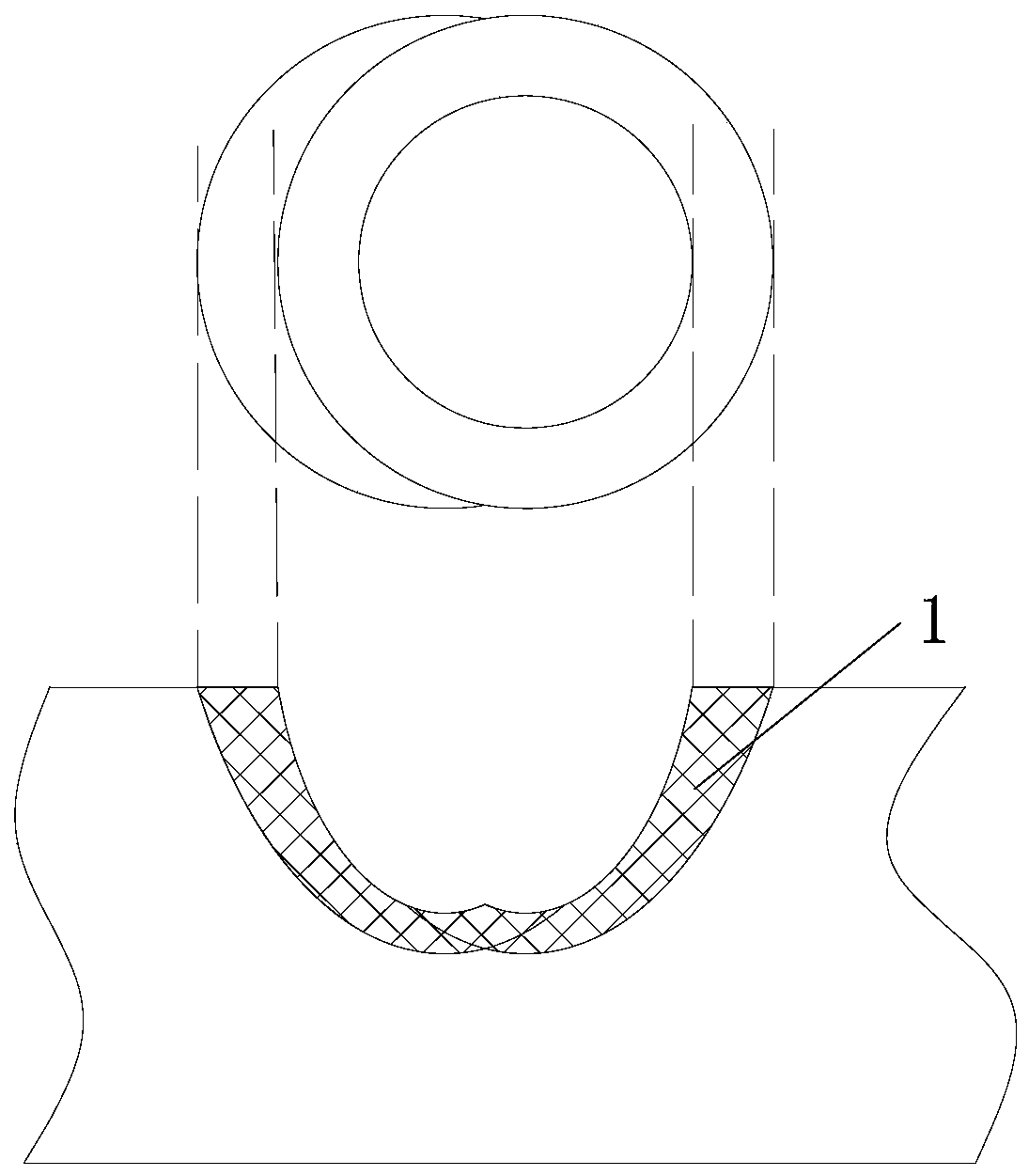

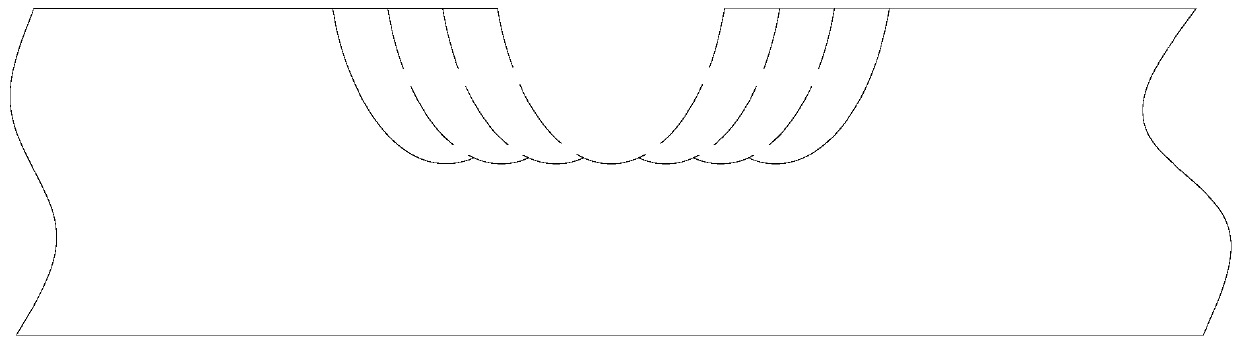

[0028] The most basic structural unit in a microfluidic chip is a meandering arrangement of microchannels, so the processing of microchannels is the basis for chip fabrication and application. The invention provides a laser preparation method of a microchannel of a microfluidic chip. The method is a laser direct writing etching method, which can adjust the distance between the laser beam and the substrate through a two-dimensional precision displacement system according to a graphic designed by a computer. The relative mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com