Method for manufacturing transfer printing roller tool with gulf stream pattern

A manufacturing method and Gulfstream technology are applied in the manufacturing field where a Gulfstream pattern can be formed on the transfer wheel, which can solve the difference in the ink content of the Gulfstream channel, affect the transfer effect of the transfer wheel, and the low ink content and other problems to achieve the effect of avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In the following, the technical means adopted by the present invention to achieve the intended purpose of the invention will be further described in conjunction with the accompanying drawings and preferred embodiments of the present invention.

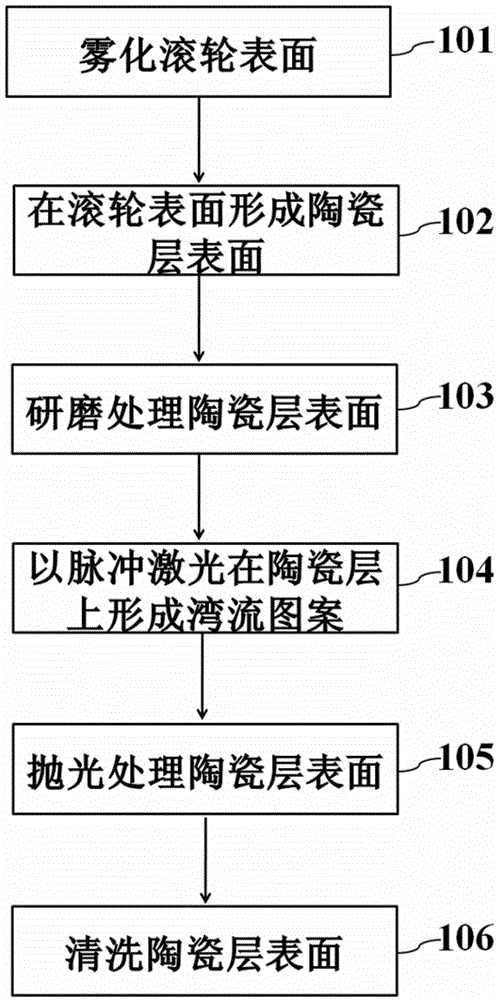

[0053] see figure 1 As shown, the manufacturing method of the transfer wheel with the Gulfstream pattern in the present invention includes the step 101 of atomizing the surface of the roller, the step 102 of forming a ceramic layer on the surface of the roller, the step 103 of grinding the surface of the ceramic layer, and using pulsed laser ( pulse laser) forming a Gulfstream pattern on the ceramic layer 104, polishing the surface of the ceramic layer 105, and cleaning the surface of the ceramic layer 106.

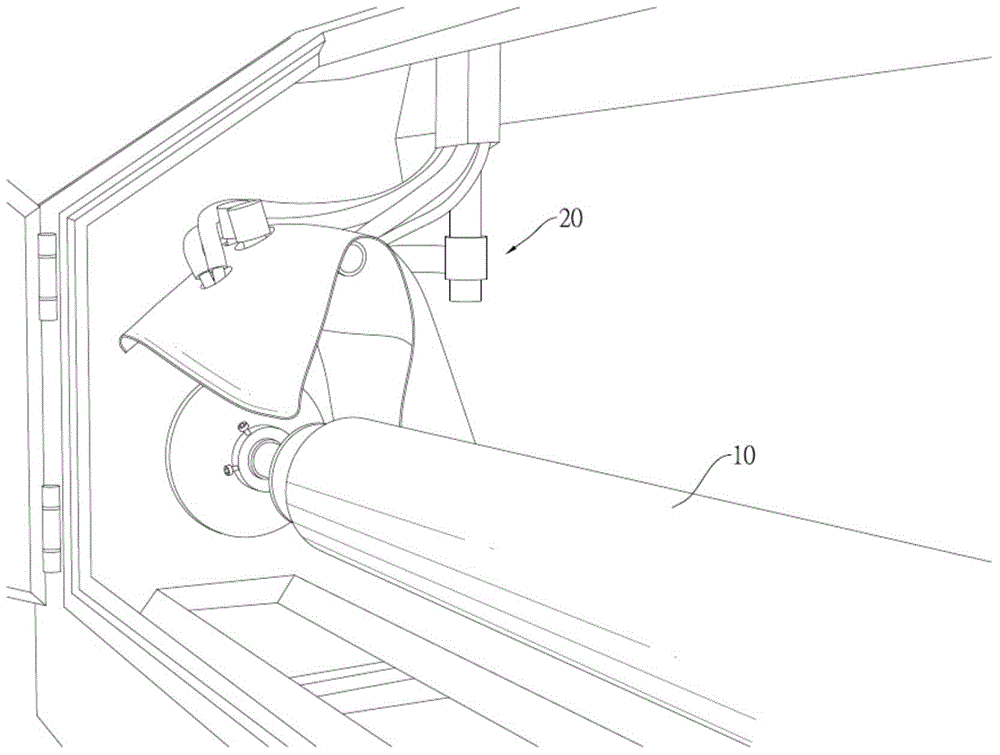

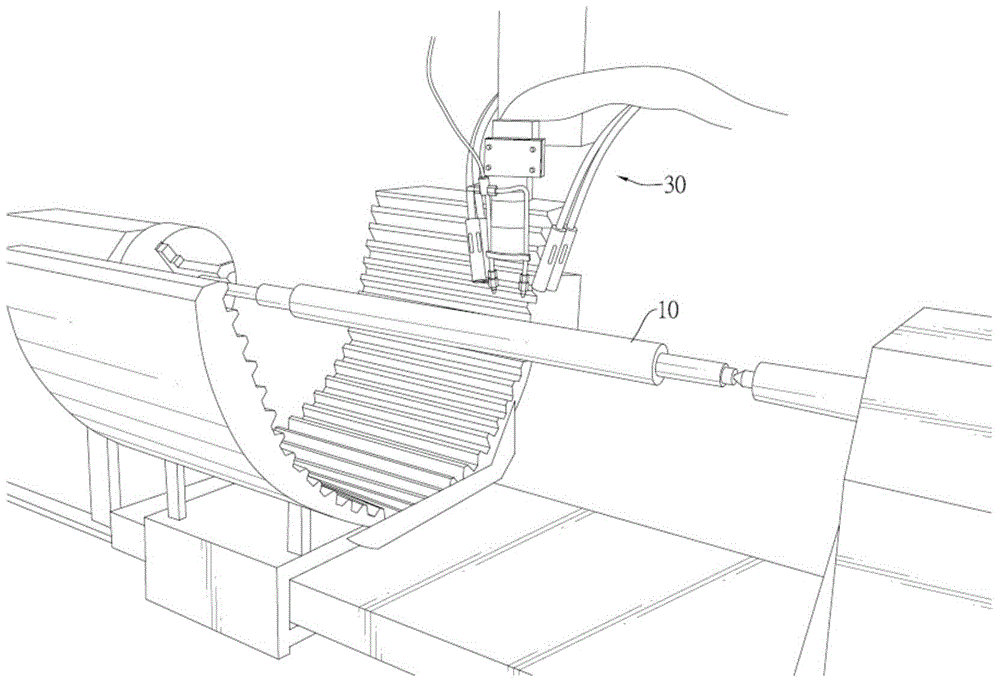

[0054] Cooperate see figure 2 As shown, in the above-mentioned step 101 of atomizing the surface of the roller, the surface of the metal roller 10 is subjected to fogging treatment, so that the surface of the roller 10 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com