Tunable left-handed metamaterial based on phase-change material

A technology of phase change materials and metamaterials, applied in the field of tunable negative refractive index devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

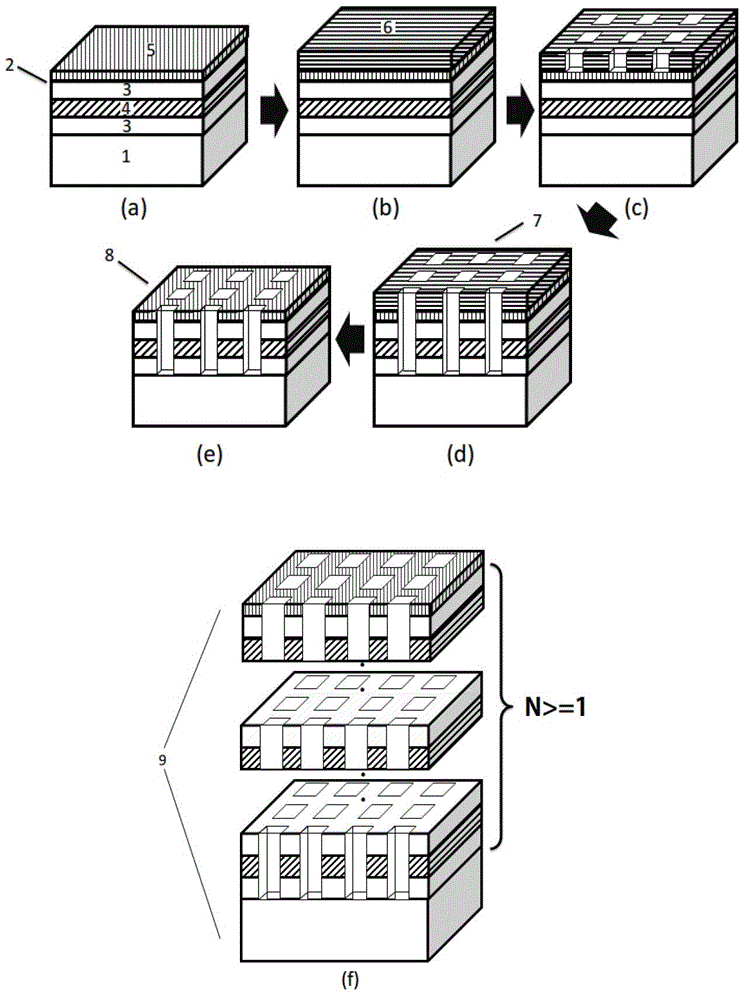

[0020] First, a multilayer structure of N (N>=1) layers (metal layer 3-phase change material layer 4-metal layer 3-oxidation layer 5) 2 is formed on a glass substrate 1 by a material growth process, as shown in the attached figure 2 (a) shown.

[0021] Second, deposit SiO on the multilayer structure 2 2 film as a mask 6, as attached figure 2 (b) shown.

[0022] Then, the designed periodic hole matrix sample is transferred to the mask through the mask process, as shown in the attached figure 2 (c) shown. Among them, the structure design can adopt algorithms such as finite time domain difference method and finite element method.

[0023] Then, through an etching process, a periodic hole matrix 7 is prepared on the 2 material, as shown in the attached figure 2 as shown in (d)

[0024] Finally, the mask 6 is removed to obtain the tunable left-handed metamaterial 8, as shown in the attached figure 2 (e) shown. Among them, the left-handed metamaterial 9 based on multi-l...

Embodiment 2

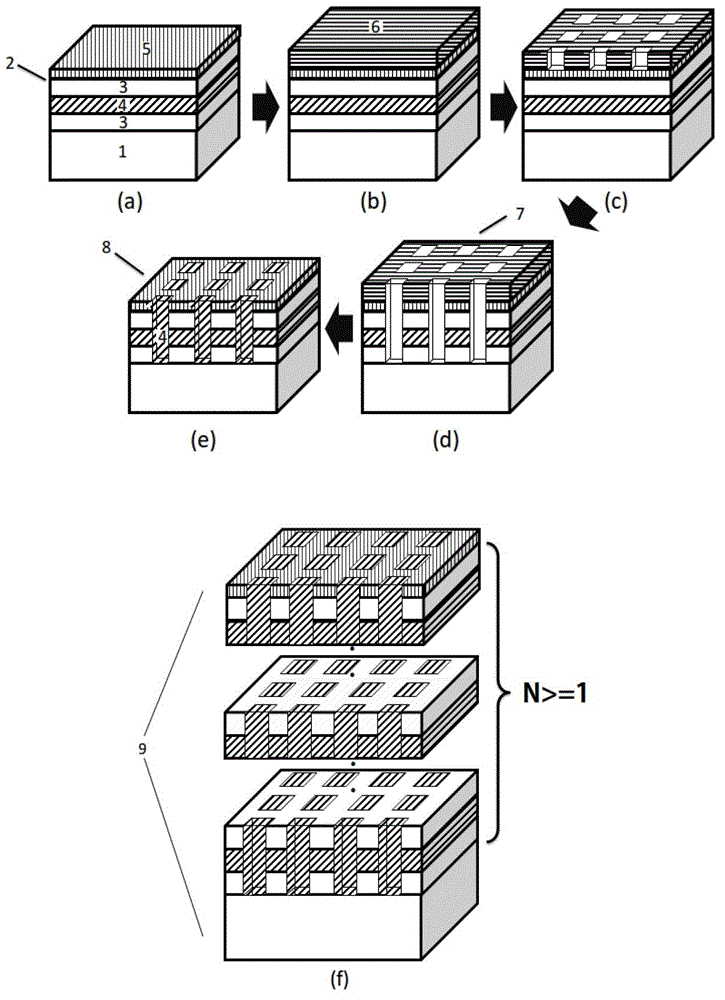

[0026] First, a multilayer structure of N (N>=1) layers (metal layer 3-phase change material layer 4-metal layer 3-oxidation layer 5) 2 is formed on a glass substrate 1 by a material growth process, as shown in the attached image 3 (a) shown.

[0027] Second, deposit SiO on the multilayer structure 2 2 film as a mask 6, as attached image 3 (b) shown.

[0028] Then, the designed periodic hole matrix sample is transferred to the mask through the mask process, as shown in the attached image 3 (c) shown. Among them, the structure design can adopt algorithms such as finite time domain difference method and finite element method.

[0029] Then, through an etching process, a periodic hole matrix 7 is prepared on the 2 material, as shown in the attached image 3 as shown in (d)

[0030] Finally, the mask 6 is removed, and the phase-change material 4 is injected into the hole matrix 7 to seal the holes to obtain a tunable left-handed metamaterial 8, as shown in the attached ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com