Shank structure for cutter clamping

A tool handle structure and cutting tool technology, which is applied to the accessories of tool holders, manufacturing tools, turning equipment, etc., can solve the problems of high precision of taper surface, high use cost, uneven force, etc., and achieve good connection stability, Low cost of use and good positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

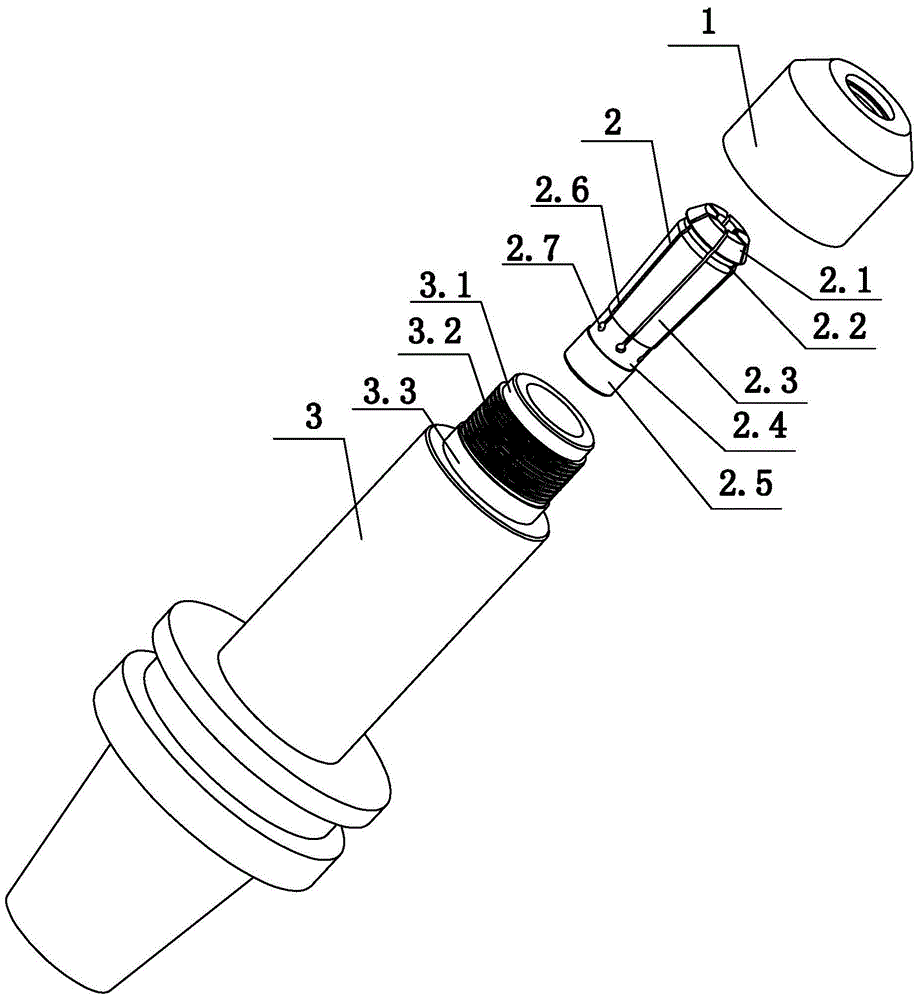

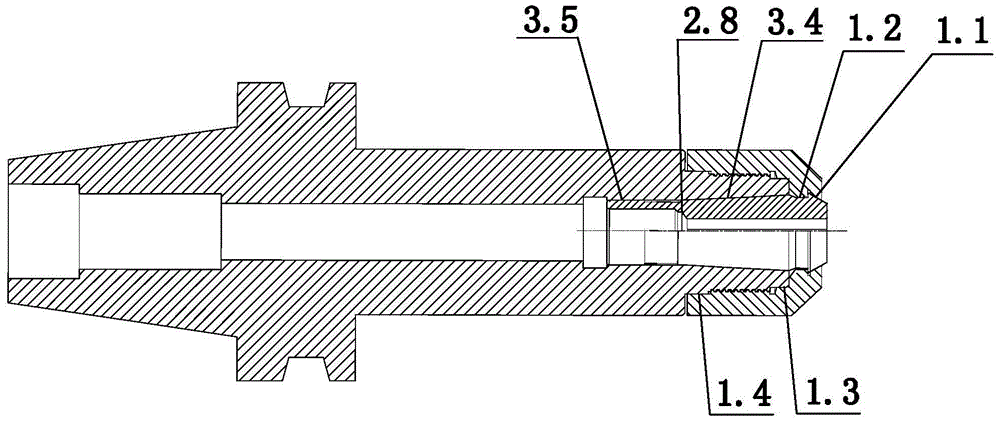

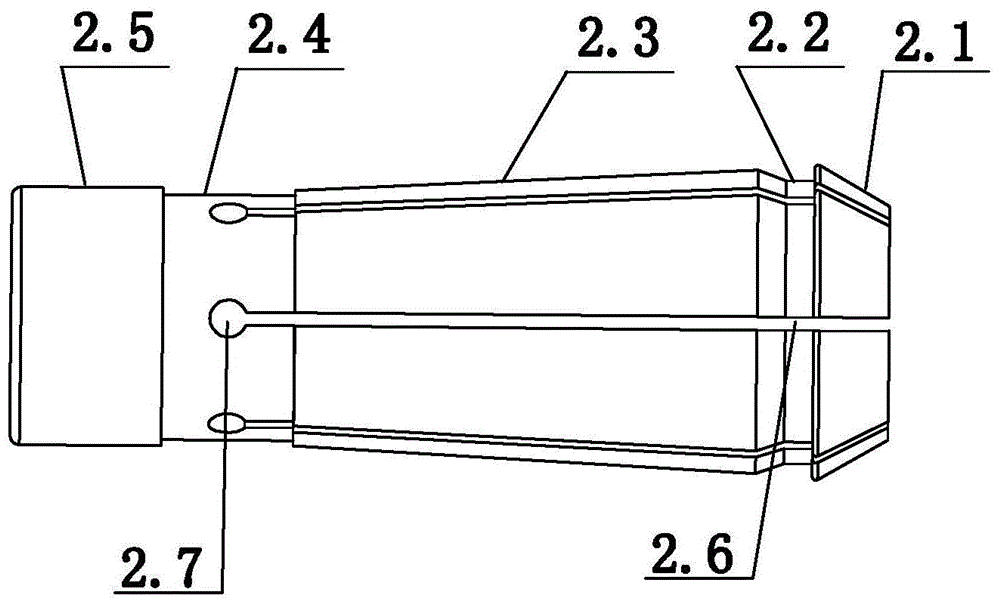

[0018] Such as Figure 1-3 As shown, a handle structure for tool clamping includes a handle body 3, a collet 2 and a nut 1, and the front end of the collet 2 is provided with an inclined surface for matching with the inner inclined wall 1.1 of the nut 1 2.1 and the annular snap groove 2.2 for engaging with the snap ring 1.2 provided in the inner cavity of the nut 1, and the middle section of the collet 2 is an outer cone section 2.3, and the front part of the tool handle body 3 is provided for engaging with the nut. 1, the matching connecting part, the tool handle body 3 is provided with a hollow shaft hole, and the inner cavity of the shaft hole is provided with an inner cone section 3.4 for matching with the outer cone section 2.3 of the collet 2, and the collet 2 is provided with multiple The sectional groove 2.6 that can shrink along the direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com