Deformation rectifying method for plate carburizing and quenching gears and special tool for deformation rectifying method

A carburizing and quenching, gear technology, applied in the direction of quenching agent, furnace type, manufacturing tools, etc., can solve the problems of negligible compensation, difficulty in suppressing deformation, and inability to establish a temperature field, so as to reduce the scrap rate and inhibit the re-quenching. The effect of swelling and cooling speed reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

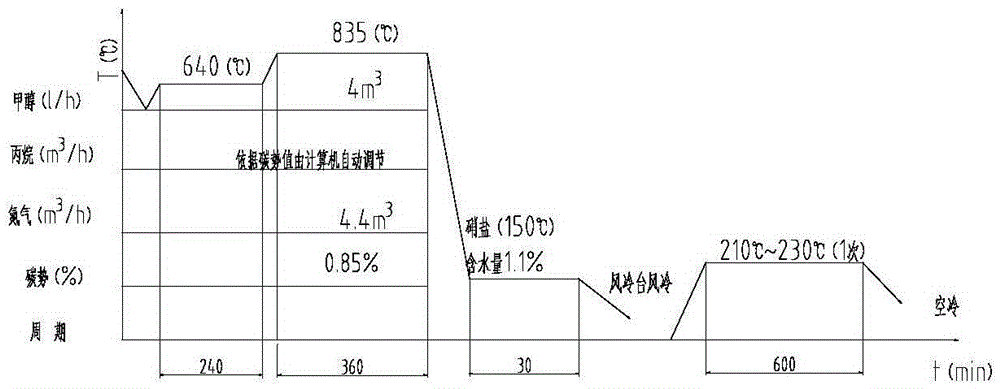

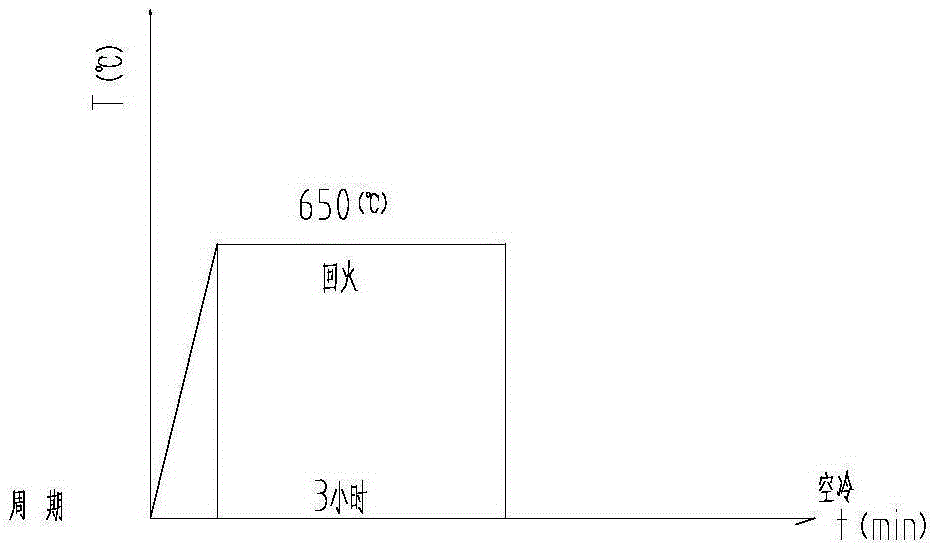

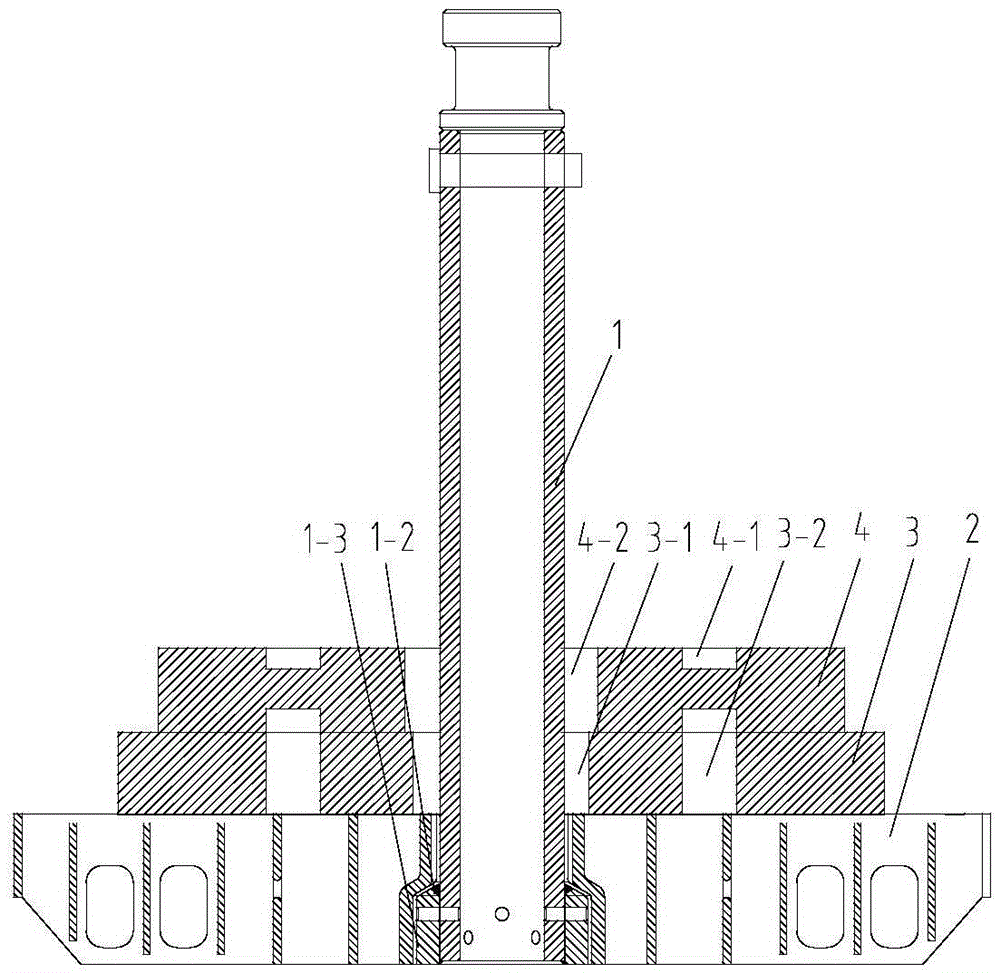

Embodiment 1

[0031] The disc carburizing and quenching gear to be corrected in this embodiment is cylindrical gear 4, and the specific parameters are as follows: modulus 9, number of teeth 106, tooth profile angle 20°, addendum height coefficient 1.125, total tooth height 23.6, radial displacement coefficient -0.4085, helix angle 4°, helix direction left, number of teeth across 12, average length of common normal line 316.48, gear pair center distance 555, its structure see figure 1 , the two end surfaces respectively have weight-reducing ring grooves 4-1, and the center has a shaft hole 4-2. The special tooling used includes a grid-shaped chassis 2 with a vertical central boom 1 and a tray 3 placed on the chassis. The bottom of the boom 1 has an enlarged diameter section 1-3 passing through a transition cone 1-2. The specific structure of chassis 2 is as Figure 4 and Figure 5 As shown, the center of the bottom of the disc body 2-1 has a positioning hole matching the suspender transiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com