Electrolytic machining cathode device for freezing protection sleeve material and processing method

A cathode and protective cavity technology, applied in the direction of processing electrodes, electric processing equipment, electrochemical processing equipment, etc., can solve problems such as stray corrosion, improve the surface quality of workpieces, reduce uneven stray corrosion, and reduce the taper of workpieces. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the drawings:

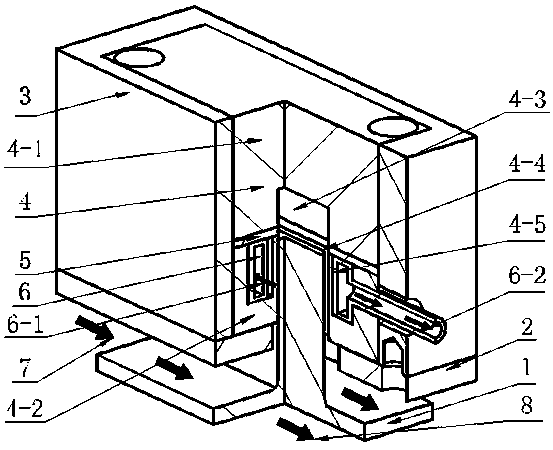

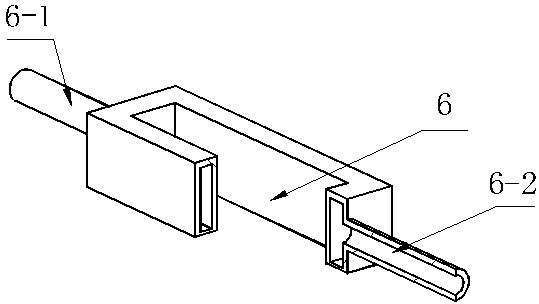

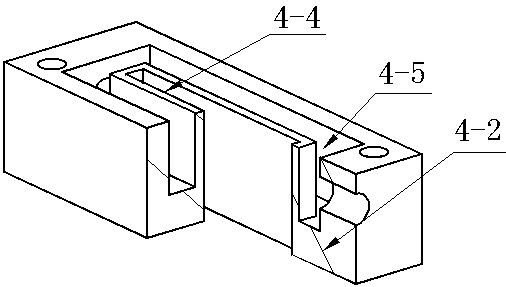

[0024] Such as figure 1 , figure 2 with image 3 As shown, a cathode system for electrochemical machining of a freezing protection jacket material for implementing the present invention is characterized in that it includes:

[0025] The main steps of electrochemically machining a workpiece using the present invention mainly include the following processes:

[0026] Step 1). Assemble the components of each cathode device, and connect the assembled cathode device together with the cathode rod to the feed spindle of the machine tool;

[0027] Step 2). Connect the refrigerant inlet and outlet nozzles to the inlet and outlet of the refrigerant capsule respectively;

[0028] Step 3). Install and fix the workpiece. After determining the relative position of the workpiece and the cathode in the machine tool, connect the water-sealing fixture to the cathode device;

[0029] Step 4). Feed th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com