Conical electrolyte groove and micro electrolytic wire cutting and piercing processing method

A technology of electrolyte tank and tapered tank, which is applied in the field of tapered electrolyte tank and micro-electrolytic wire cutting and perforation processing, and can solve problems such as secondary discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

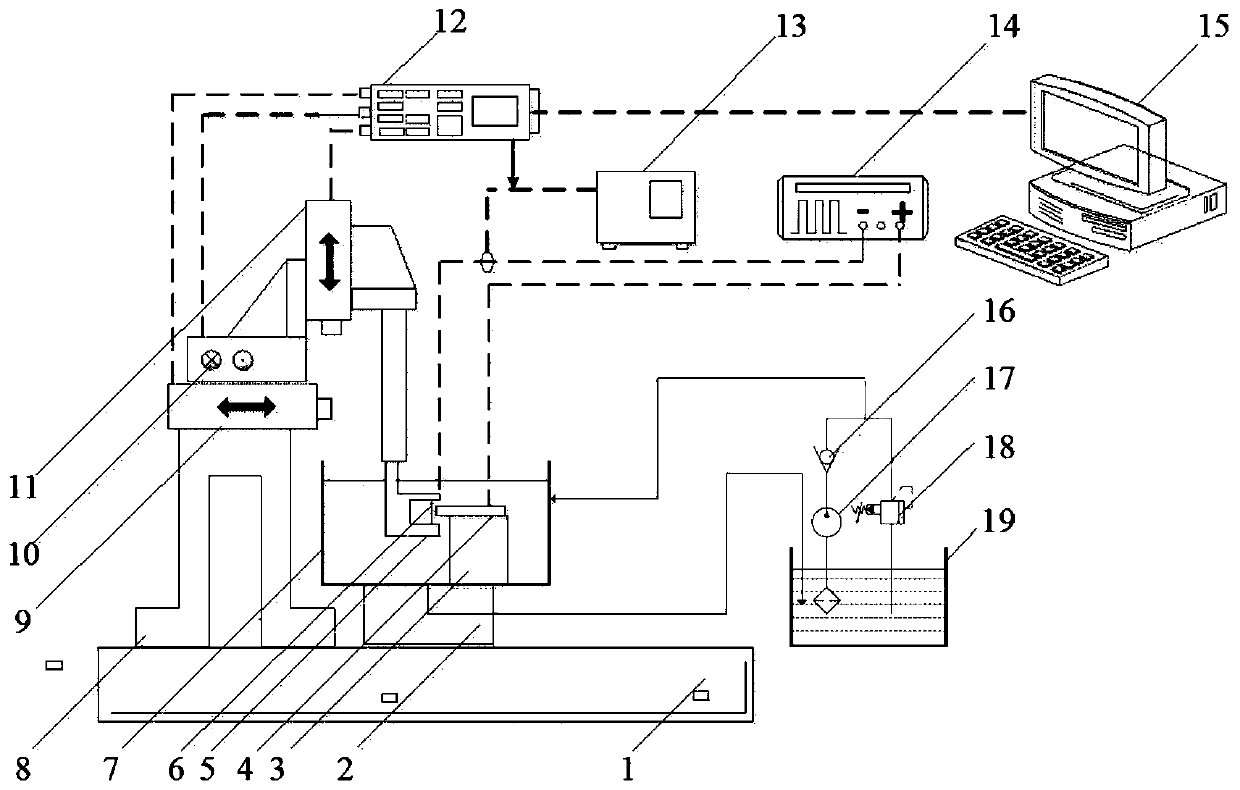

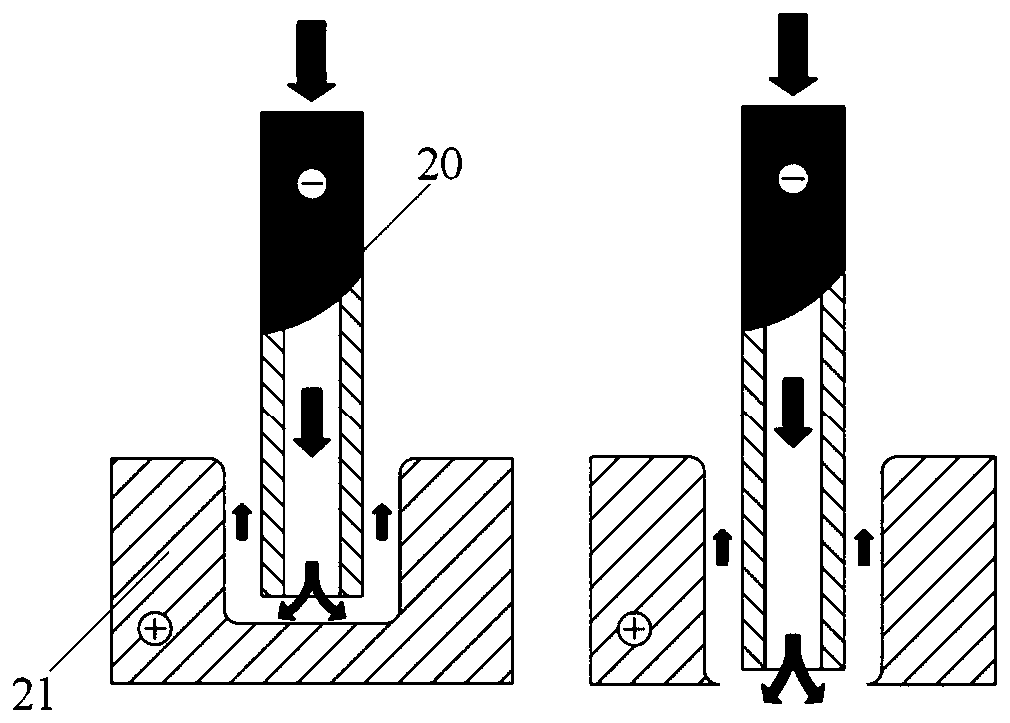

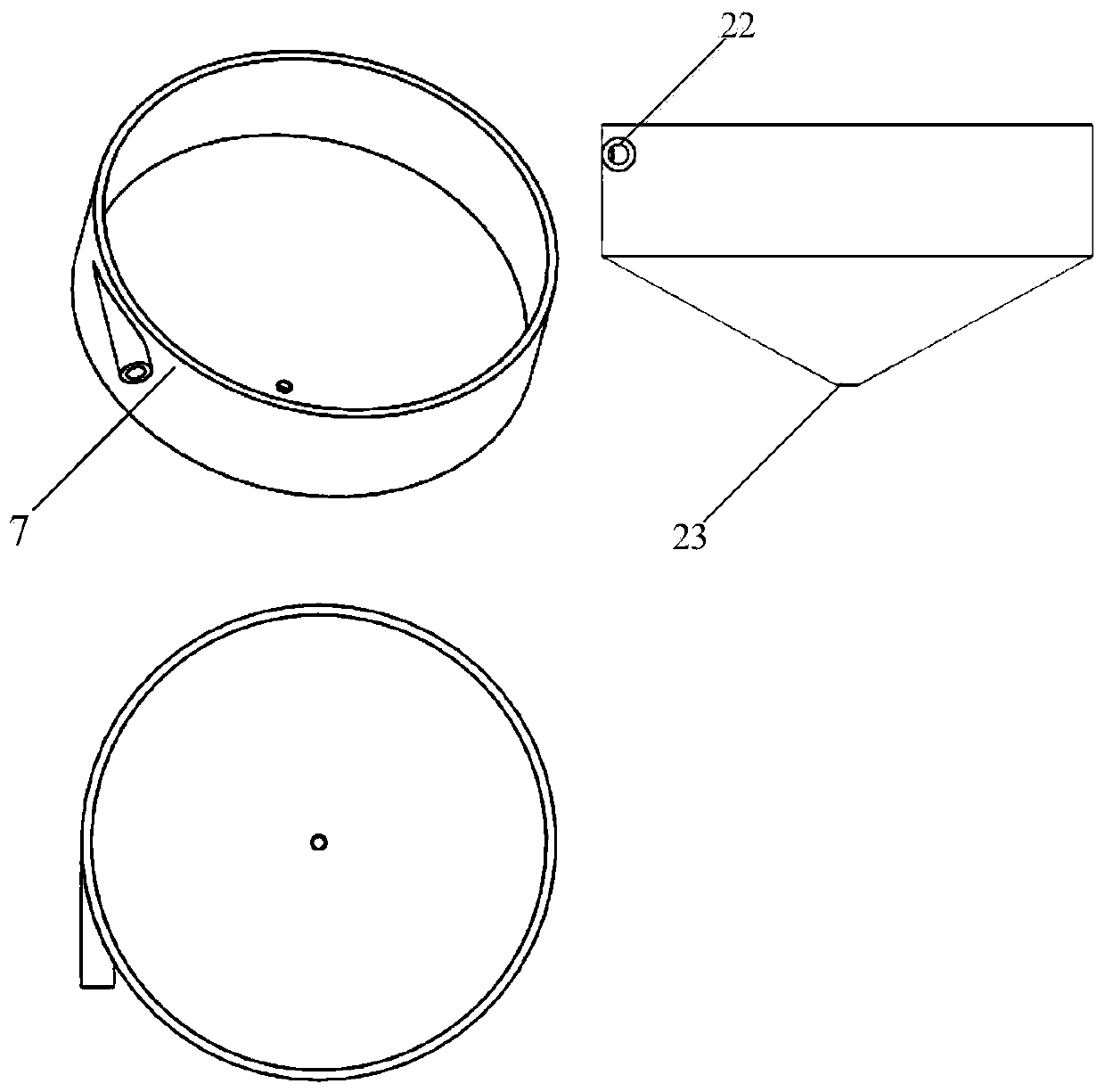

[0018] figure 1 It is a schematic diagram of the overall structure of the micro-electrolytic wire cutting process with buffer circulation flushing. The main components of the structure are vibration isolation platform 1, PZT platform 2, workpiece fixture 3, workpiece 4, tool electrode fixture 5, tool electrode 6, electrolytic cell 7, motion platform base 8, Y-axis precision mobile platform 9, X-axis Precision mobile platform 10, Z-axis precision mobile platform 11, motion control card 12, oscilloscope 13, ultra-high frequency narrow pulse power supply 14, industrial computer 15, check valve 16, metering pump 17, overflow valve 18, electrolyte water tank 19 . The machining process is briefly described as follows: the X, Y, and Z axis precision mobile platforms 10, 9, and 11 are controlled by the industrial computer 15 and the motion control card 12, so that the tool electrode 6 can be fed and moved in a three-dimensional space to realize complex trajectory processing; By cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com