Low-temperature precision electrolytic machining method

A processing method, low-temperature technology, applied in the field of precision, low-temperature electrolytic precision machining, ultra-precision electrolytic machining, can solve the problems of poor hole wall quality, small hole inlet surface quality, etc., to achieve weakened ion movement ability, stable processing process, weakened The effect of stray corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

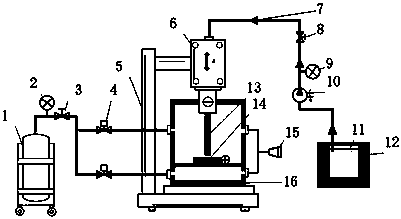

[0025] Combine below figure 1 Detailed description of the general processing process: low temperature gas 1 is injected into the low temperature insulation box 16 through a pipeline, and the flow valve 4 controls the gas flow. The flow to the large volume at the upper part of the low-temperature insulation box 16 is small, and the flow at the small volume at the lower part is larger, so that the temperature of the workpiece 14 and the processing area is different, and the workpiece 14 is in a lower temperature state. The low-temperature electrolyte 11 cooled by the low-temperature water bath 12 passes through the metering pump 10 and is sprayed from the tube electrode 13 along the heat-preserving pipeline 7 to the workpiece. At the same time, the numerical control shaft head 6 is fed downward to process a small portion on the workpiece 14. hole. Because the whole process is carried out at low temperature, the taper of the processed holes is small, and the stray corrosion pheno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com