Machining method and device for axial purge electrolytic wire cutting assisted by workpiece reciprocating motion

A reciprocating motion and cutting processing technology, which is applied in the field of workpiece reciprocating motion assisted axial flushing electrolytic wire cutting processing, can solve the problems of difficulty in updating the electrolyte and difficulty in removing electrolytic products, and achieves faster updating, faster electrolytic reaction, and improved electrolysis. The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

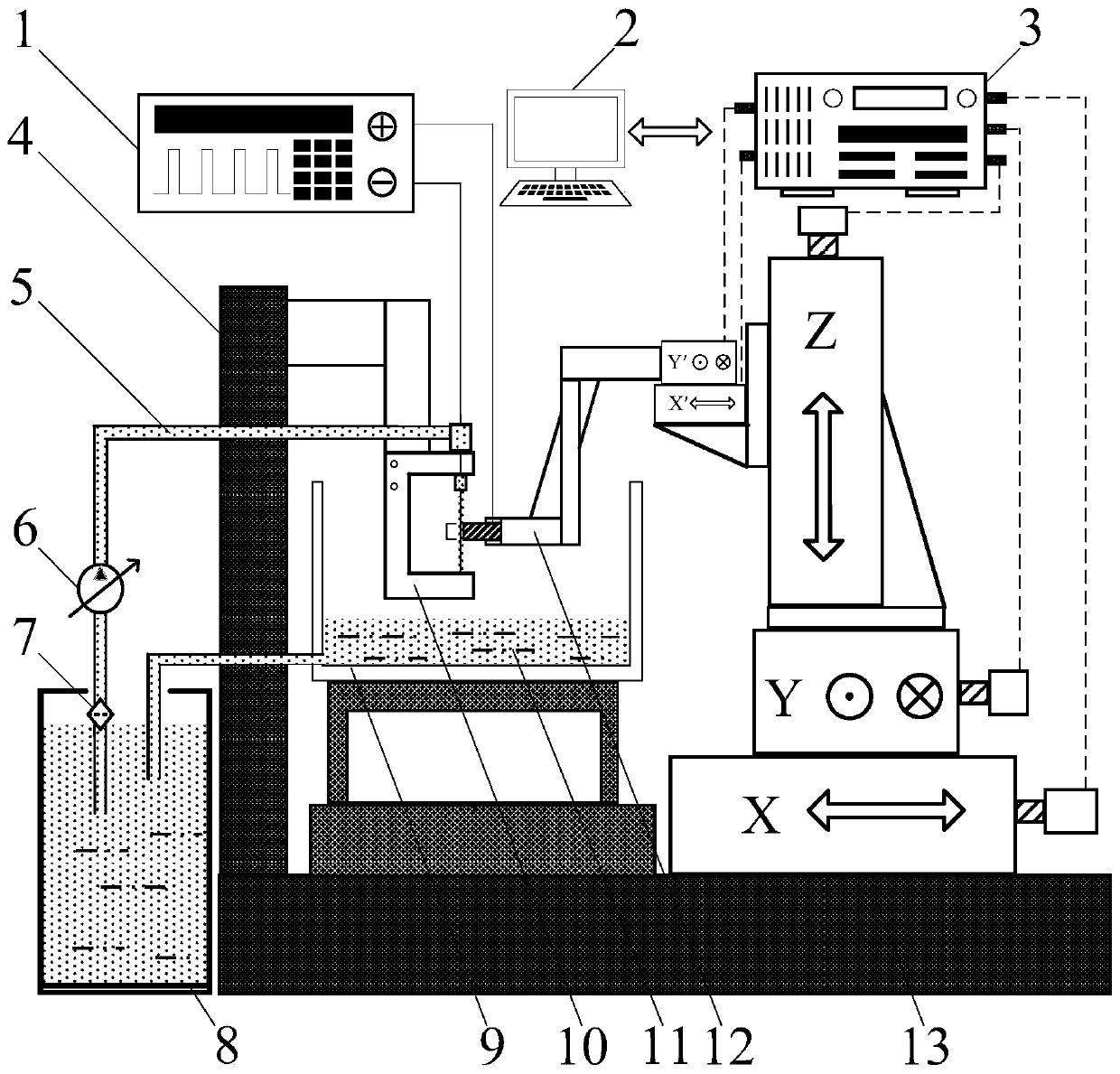

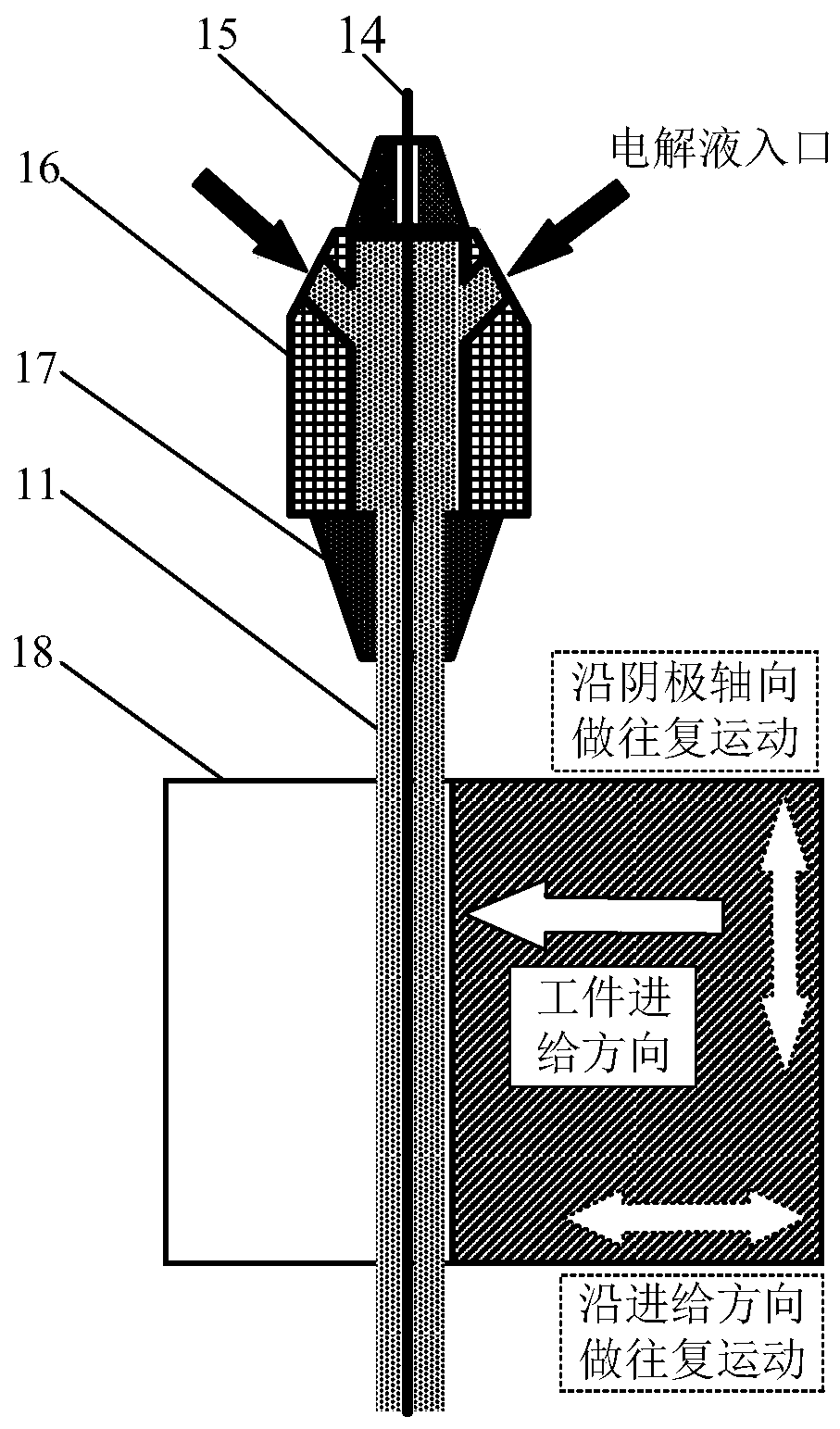

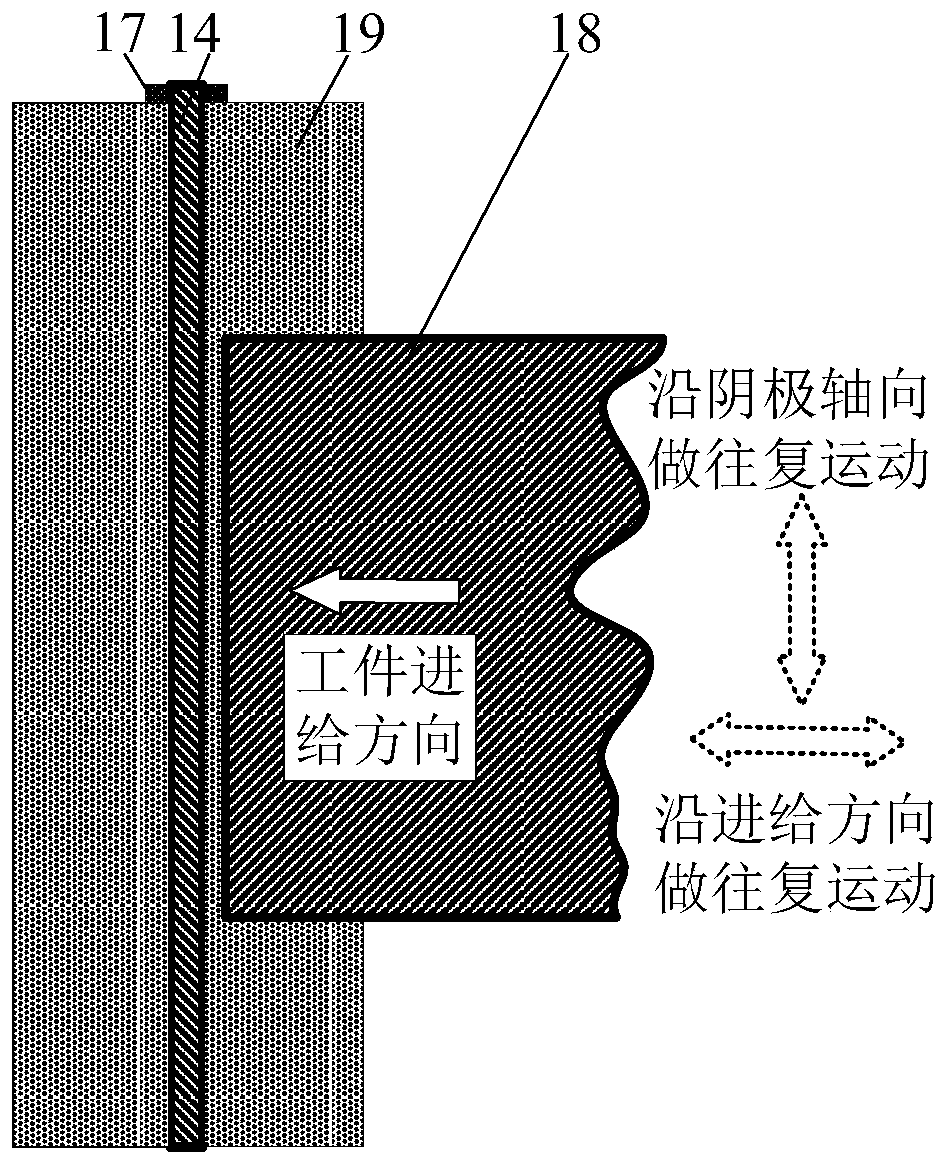

[0022] according to Figure 1-2 As shown, the overall structure of a workpiece reciprocating motion assisted axial flushing electrolytic wire cutting device proposed by the present invention mainly includes a five-axis machine tool system, an electrolyte circulation system, a pulse power supply 1, an anode system, and a wire electrode system; The machine tool system includes X-axis table, Y-axis table, Z-axis table, Xʹ-axis table, Yʹ-axis table, and machine tool table; the Xʹ-axis of the Xʹ-axis table is installed on the Yʹ-axis table, and the Yʹ-axis works The Yʹ axis of the table is installed on the Z-axis table, the Z-axis of the Z-axis table is installed on the Y-axis table, the Y-axis of the Y-axis table is installed on the X-axis table, and the X-axis of the X-axis table is installed on the On the machine tool table 13; the five-axis machine tool system also includes an industrial computer 2 and a motion control card 3; the anode system includes an anode fixture 12 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com