Revolving body surface high boss electrolytic machining tool electrode assembly and electrolytic machining method

A technology for processing tools and electrode components, which is applied in the direction of processing electrodes, electric processing equipment, electrochemical processing equipment, etc., can solve the problems of difficult control of processing stability, complex flow field, complex motion form, etc., and achieve favorable processing stability , avoid secondary corrosion, reduce the effect of stray corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The implementation process of the present invention is illustrated in conjunction with the accompanying drawings:

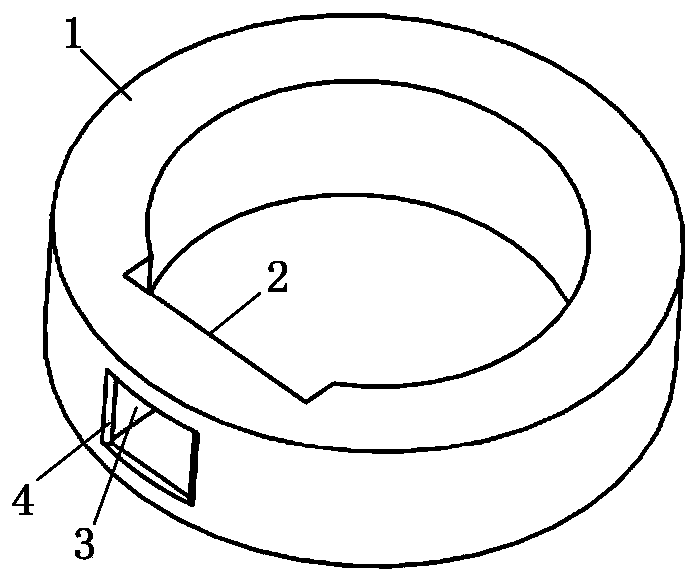

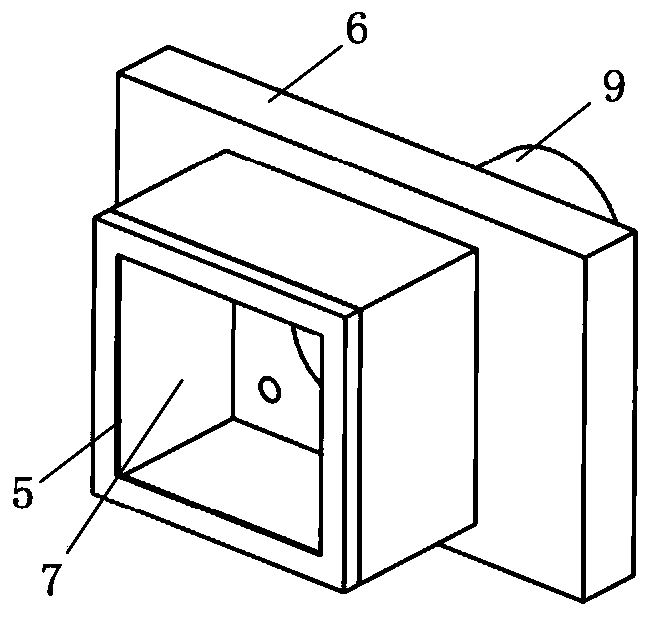

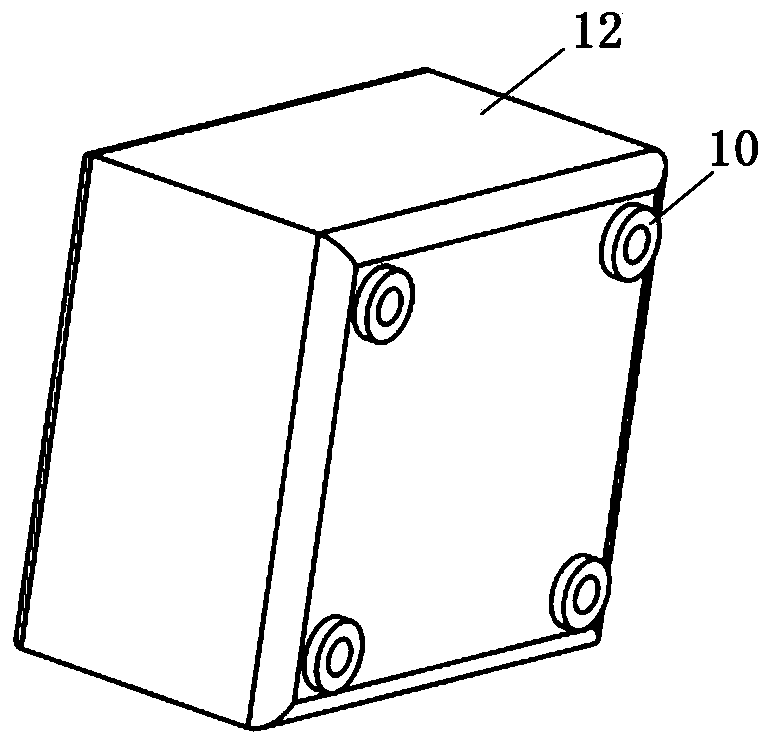

[0022] figure 1 It is a schematic diagram of the tool cathode structure; the tool cathode 1 is a rotator structure with a hollow groove structure 3 on its surface, a protruding circular structure 4 on the top of the groove structure 3, and a planar structure 2 inside the tool cathode 1. figure 2 It is a schematic diagram of the structure of the first insulating cavity; the first insulating cavity 8 is installed on the plane structure 2 inside the tool cathode 1, and the outer side of the first insulating cavity cavity 7 is connected with the inner wall and groove structure of the protruding round structure 4 on the tool cathode 1 3 side walls fit tightly. image 3 It is a schematic diagram of the structure of the second insulating cavity; there are four bottom mounts 10 at the bottom of the second insulating cavity 12, which are fixed inside the first in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com