Machining method of semiconductor chip

A processing method and semiconductor technology, applied in the direction of semiconductor devices, etc., can solve problems such as chips that have not been reported, and achieve the effects of short pickling time, avoiding electric field concentration, and less metal ion contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The processing method of the present invention is as Figure 1-5 shown, including the following steps:

[0041] Diffusion is performed on wafer 1;

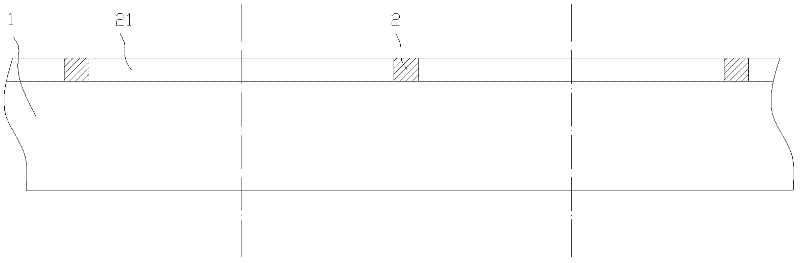

[0042] The process of setting the oxide layer 2 and photoetching the window 21 on the oxide layer 2; figure 1 ;

[0043] After the photoetching window 21, the oxide layer 2 is grid-like on the wafer surface; the internal shape of the grid is as follows: Figure 17-20 , can be a circle, a square with rounded corners, a regular hexagon or a regular octagon, and the above-mentioned planar shape can be formed during the production of the masking film according to the needs of the specific application environment.

[0044] Then process as follows:

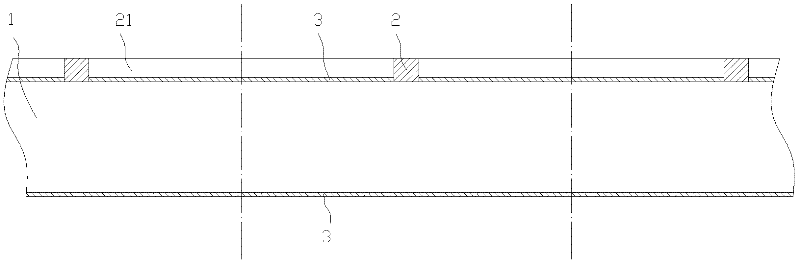

[0045] 1), set the electrode layer; such as figure 2 , coating the metal electrode layer 3 on the wafer surface in the window 21; as an electrode;

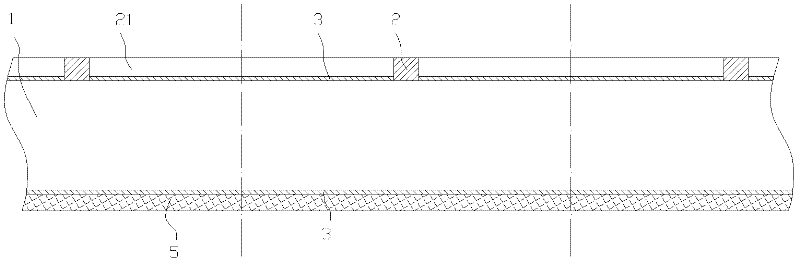

[0046] 2) One-time acid etching: using hydrofluoric acid to remove the grid-like oxide layer 2 grid on the surface of the wafer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com