Method for electrolytic machining of microtexture

A technology of micro-texture and electrolyte, applied in the direction of electric processing equipment, electrochemical processing equipment, metal processing equipment, etc., can solve the problems of difficult mask pressing and complicated mask preparation process, so as to reduce stray corrosion, The effect of low process cost and reduced cumbersome process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

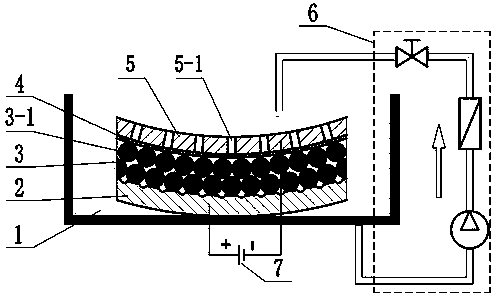

[0027] Attached below figure 1 The specific implementation process of the present invention is further described.

[0028] (1) Immerse the workpiece anode 2 in the electrolyte 1, take an appropriate amount of metal titanium particles 3-1 with a particle size of 0.2mm after wetting with the electrolyte 1, and spread it on the surface of the workpiece anode 2, and vibrate slightly to make it Form a layer 3 of uniformly arranged metal particles on the surface of the workpiece anode 2;

[0029] (2) A nylon mesh 4 with a mesh number of 150 mesh and a thickness of 0.1 mm is tightly attached to the lower surface of the metal mesh-shaped tool cathode 5 facing the metal titanium particles 3-1, and the tool cathode 5 is tightly pressed on the On the metal titanium particle layer 3, the nylon mesh 4 is placed between the tool cathode 5 and the metal titanium particle layer 3, and the metal particle 3-1 forms a metal particle layer 3 with a thickness of about 0.5mm through the pressing e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com