Precise regulating and controlling device for electrolytic machining flow field of closed structure blade

A blade and closed technology, which is applied in the field of precise control equipment for the electrolytic machining flow field of closed structure blades, can solve the problems of excessive θ angle of the cathode surface and high out-of-tolerance rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described below in conjunction with the accompanying drawings, but it is not used to limit the scope of the present invention.

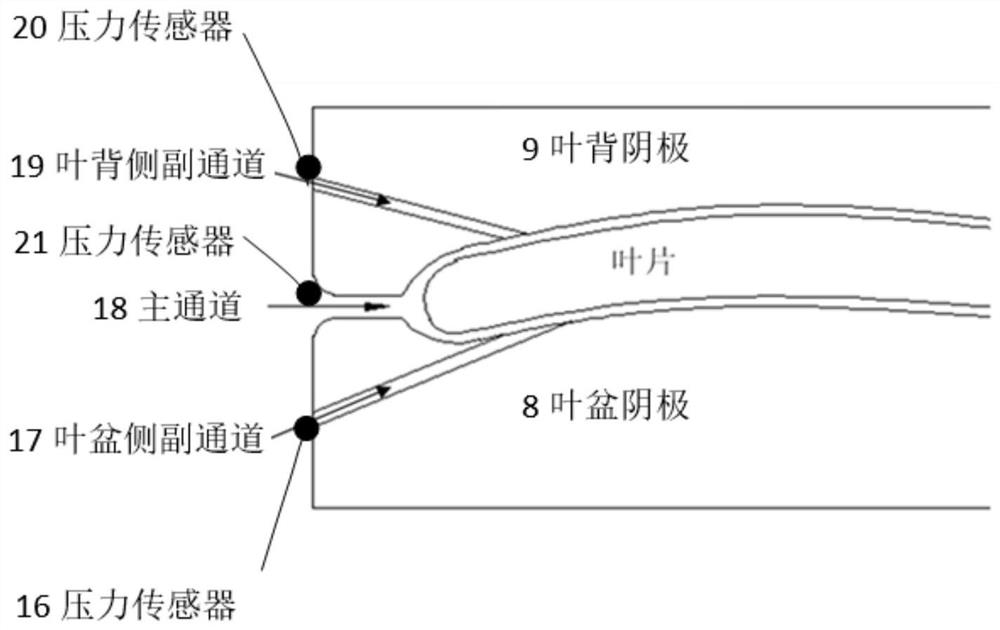

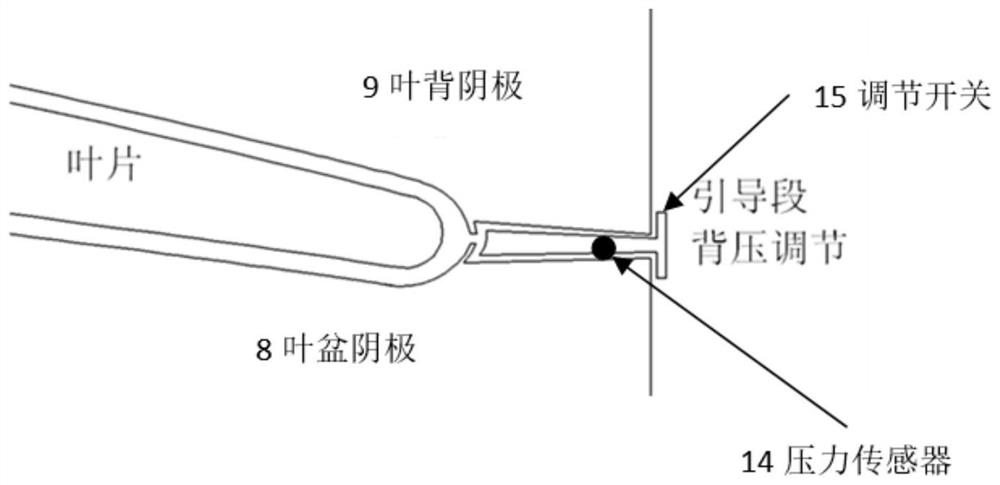

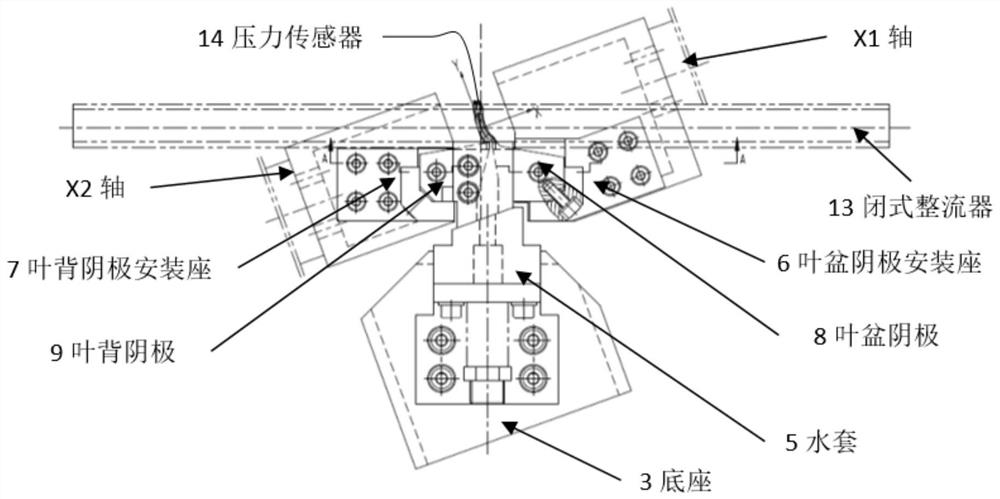

[0025] see Figure 1-Figure 4 , a closed structure blade electrolytic machining flow field precision control equipment of the present invention, comprising: an electrolytic machining device for performing electrolytic machining for a closed structure blade and an assembly device for assembling the electrolytic machining device; wherein, the The electrolytic processing device includes: a leaf back cathode provided with a leaf back side auxiliary passage, a leaf basin cathode provided with a leaf basin side auxiliary passage, a main main passage in the same direction as the leaf back side auxiliary passage and the leaf basin side auxiliary passage. The channel, the leaf back cathode and the leaf pot cathode are symmetrical in structure.

[0026] see Figure 1-Figure 2 , figure 1 It is a schematic structural diagr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com