Optical glass clarifying device and clarifying method thereof

A clarification device and optical glass technology, which is applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of lower transmittance of glass products, platinum flash point defects, platinum particles falling off, etc., and achieve improved transmittance And the effect of coloring degree index, improvement of dissolved amount, and acceleration of polymerization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

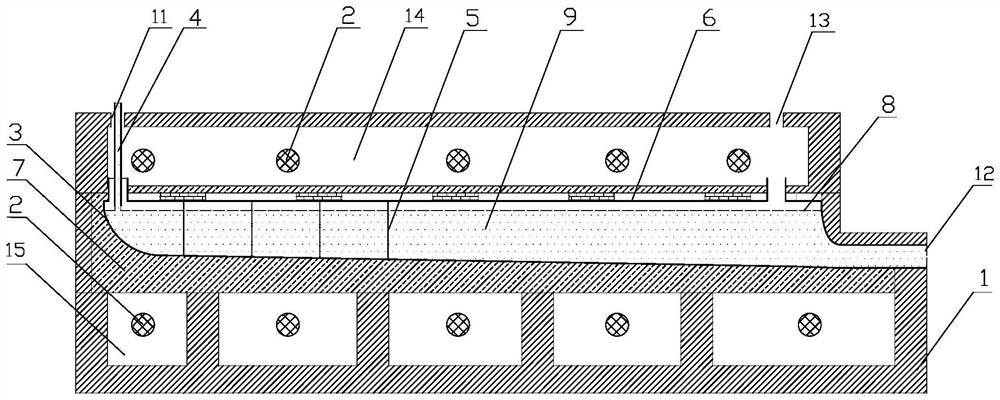

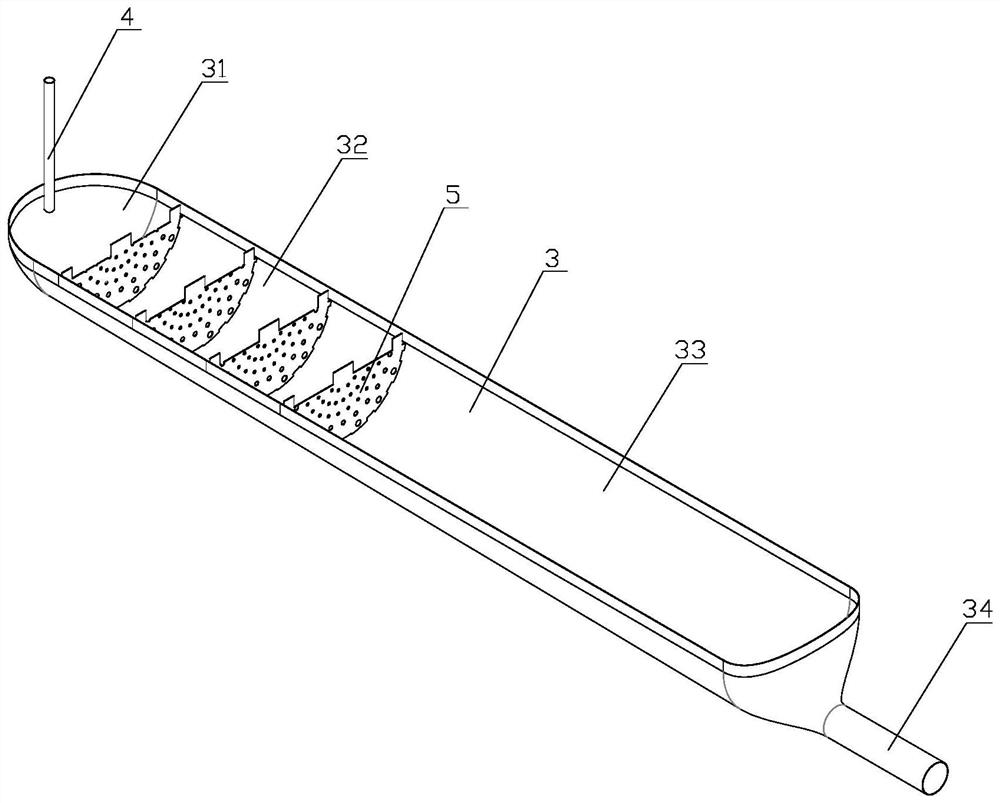

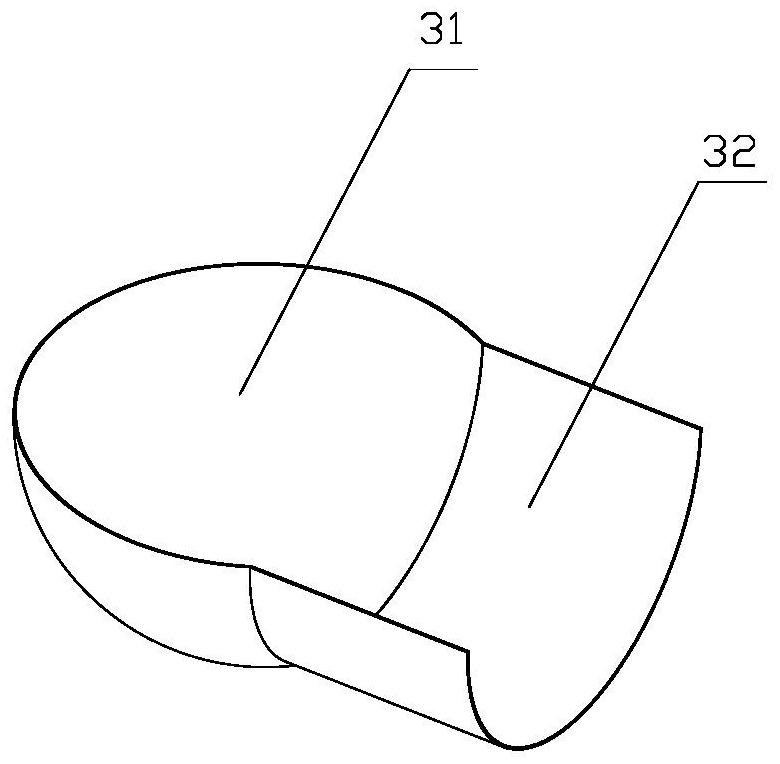

[0035] Such as figure 1 As shown, the clarification device of the present invention includes a wall 1, a platinum device and a heating element 2, the inside of the wall 1 forms a sealed space, the platinum device and the heating element 2 are arranged inside the wall 1, and the intersecting position of the platinum device and the wall 1 forms a The inlet 11 and outlet 12 of the molten glass are provided with a first exhaust hole 13 at the top rear end of the wall 1, and the platinum device in the middle isolates the inside of the wall 1 into upper and lower spaces, which respectively constitute An upper heating chamber 14 and a lower heating chamber 15 are provided.

[0036] The main function of the wall body 1 is to reduce heat loss, make the air in the space convect naturally, thereby equalizing the temperature difference in the whole space; at the same time, provide the required force support for the platinum device and the heating element 2 . The wall body 1 can be made o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com