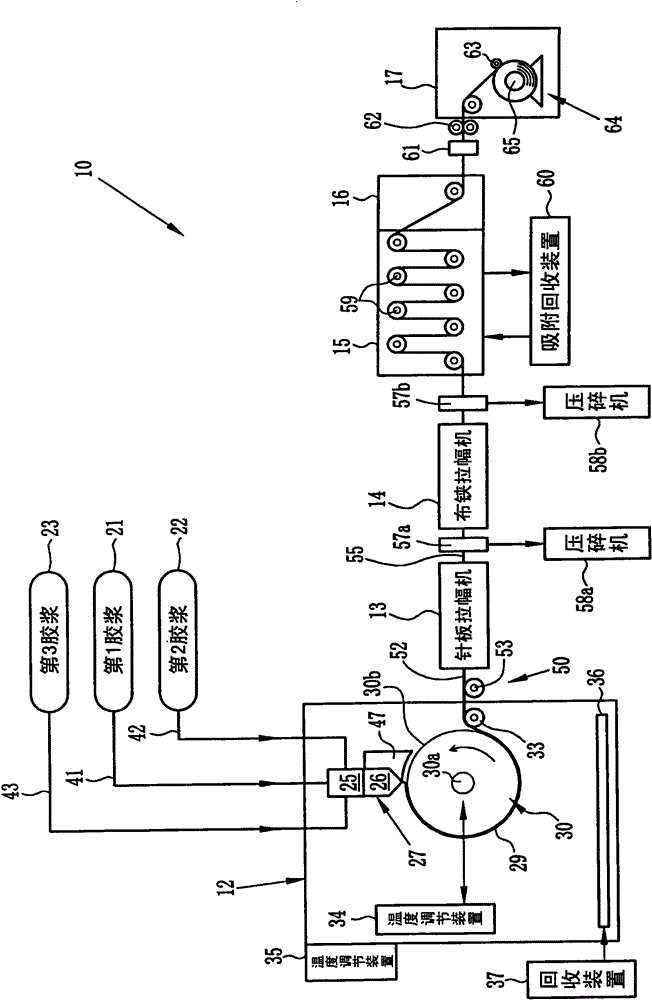

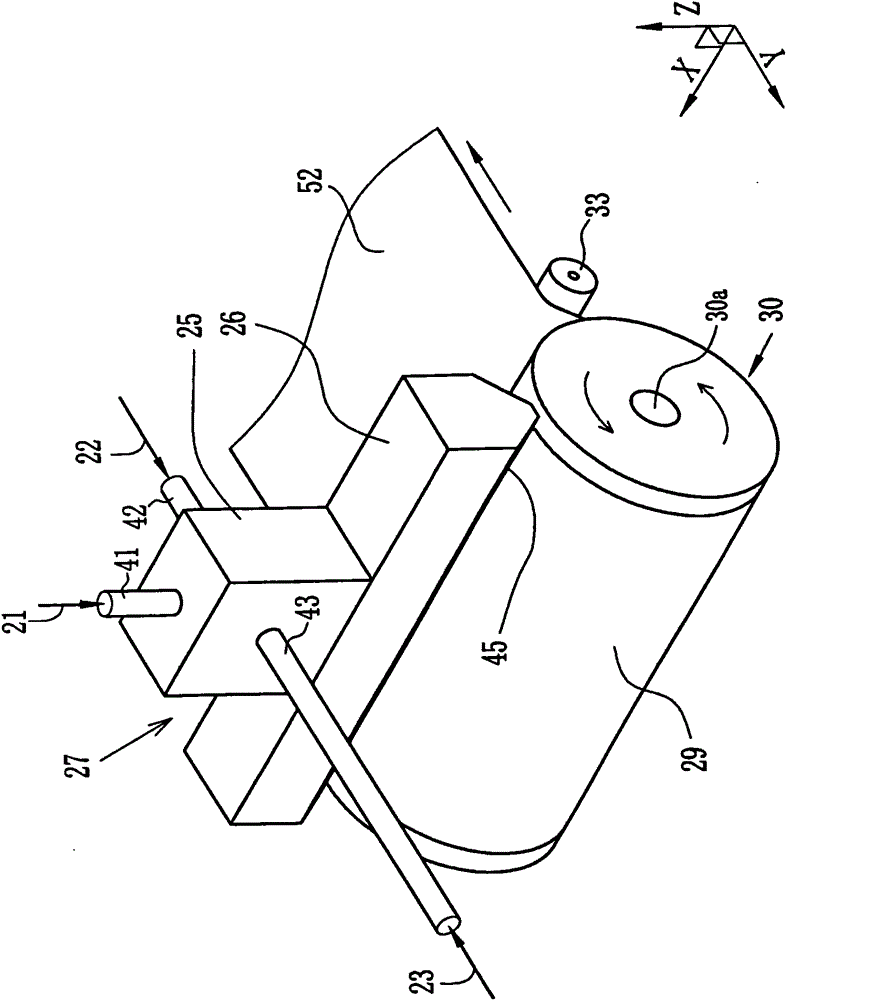

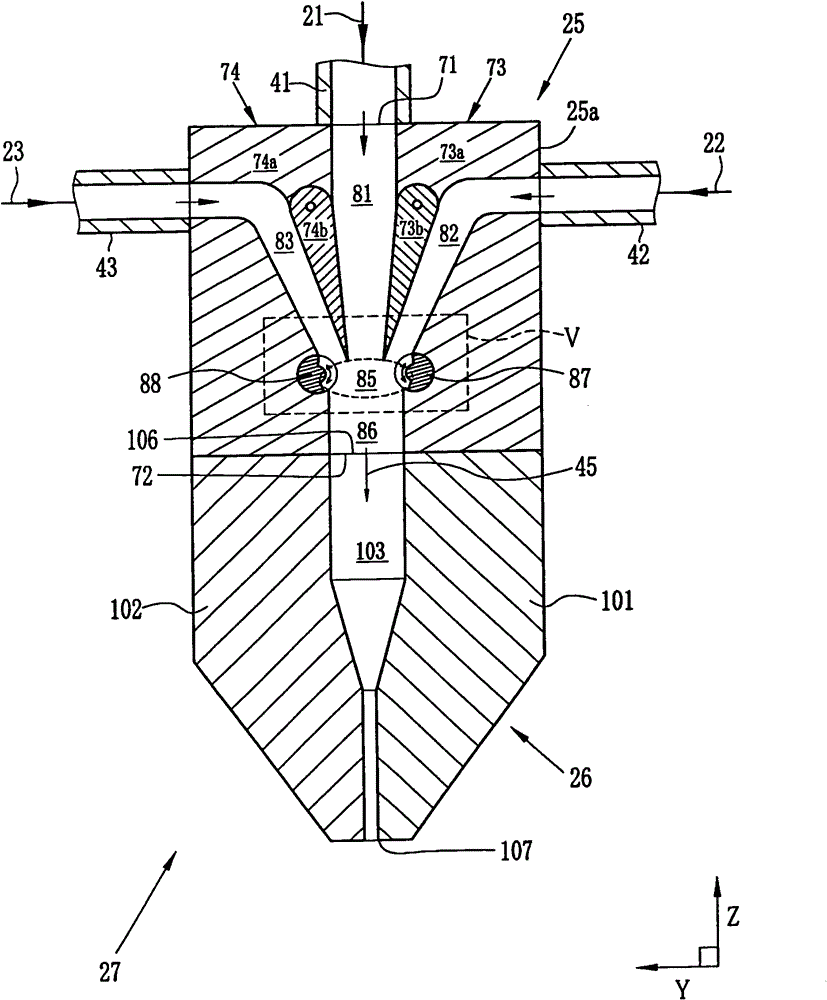

Casting device and film forming method from solution

A casting film and casting technology, applied in lamination devices, chemical instruments and methods, lamination, etc., can solve problems such as uneven thickness, achieve excellent surface conditions, and prevent uneven thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0175] Next, in order to confirm the presence or absence of the effects of the present invention, experiments 1 to 4 were performed. A detailed description will be given in Experiment 1. For Experiments 2 to 4, the description of the same conditions as in Experiment 1 will be omitted, and only the different parts will be explained.

[0176] (Preparation of cellulose acylate)

[0177] Cellulose acylates with different types and substitution degrees of acyl groups described in Table 1 were prepared. In this, sulfuric acid (7.8 parts by mass relative to 100 parts by mass of cellulose) was added as a catalyst, and carboxylic acid as a raw material of the acyl substituent was added, and the acylation reaction was carried out at 40°C. At this time, the type and degree of substitution of the acyl group are adjusted by adjusting the type and amount of carboxylic acid. In addition, the acylation reaction was followed by maturation at 40°C. Furthermore, after the aging, it was washed with...

Embodiment 2

[0231] In Experiments 1 to 4 of Example 1, except that the additive A contained in the first to third dope was replaced by the compound of A-3 described in Table 2 with the compound of A-10 described in Table 2. Except for the compound, the production of the laminated film 55 was carried out in the same manner as in Experiments 1 to 4 of Example 1. The evaluation result of the obtained laminated film 55 showed the same tendency as Experiments 1-4.

Embodiment 3

[0233] In Experiments 1 to 4 of Example 1, except that the additive A contained in the first dope to the third dope was replaced by the compound of A-3 in Table 2 with A-24 in Table 2. Except for the compound, the production of the laminated film 55 was carried out in the same manner as in Experiments 1 to 4 of Example 1. The evaluation result of the obtained laminated film 55 showed the same tendency as Experiments 1-4.

[0234] From the foregoing, it is understood that according to the present invention, it is possible to produce a laminated film having a good surface condition while suppressing unevenness in thickness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com