Technique for electrolysis processing fine slits and its devices

A processing technology and micro technology, applied in the field of micro-slot electrolytic processing methods and devices, can solve the problems of difficulty in ensuring dimensional accuracy, untimely removal of processed products, easy deformation, etc., so as to improve processing verticality and processing accuracy, and reduce processing Side clearance, the effect of improving machining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

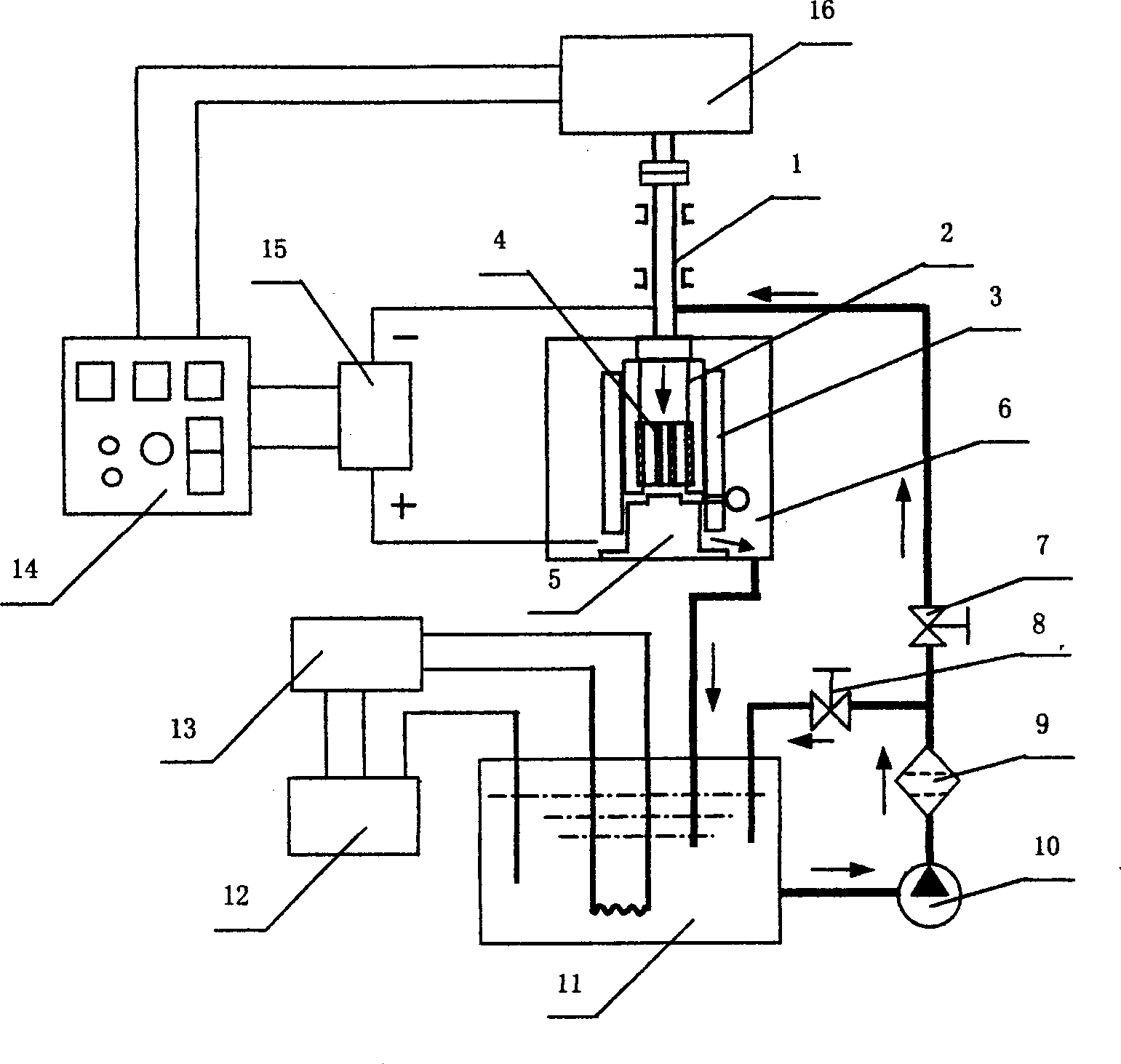

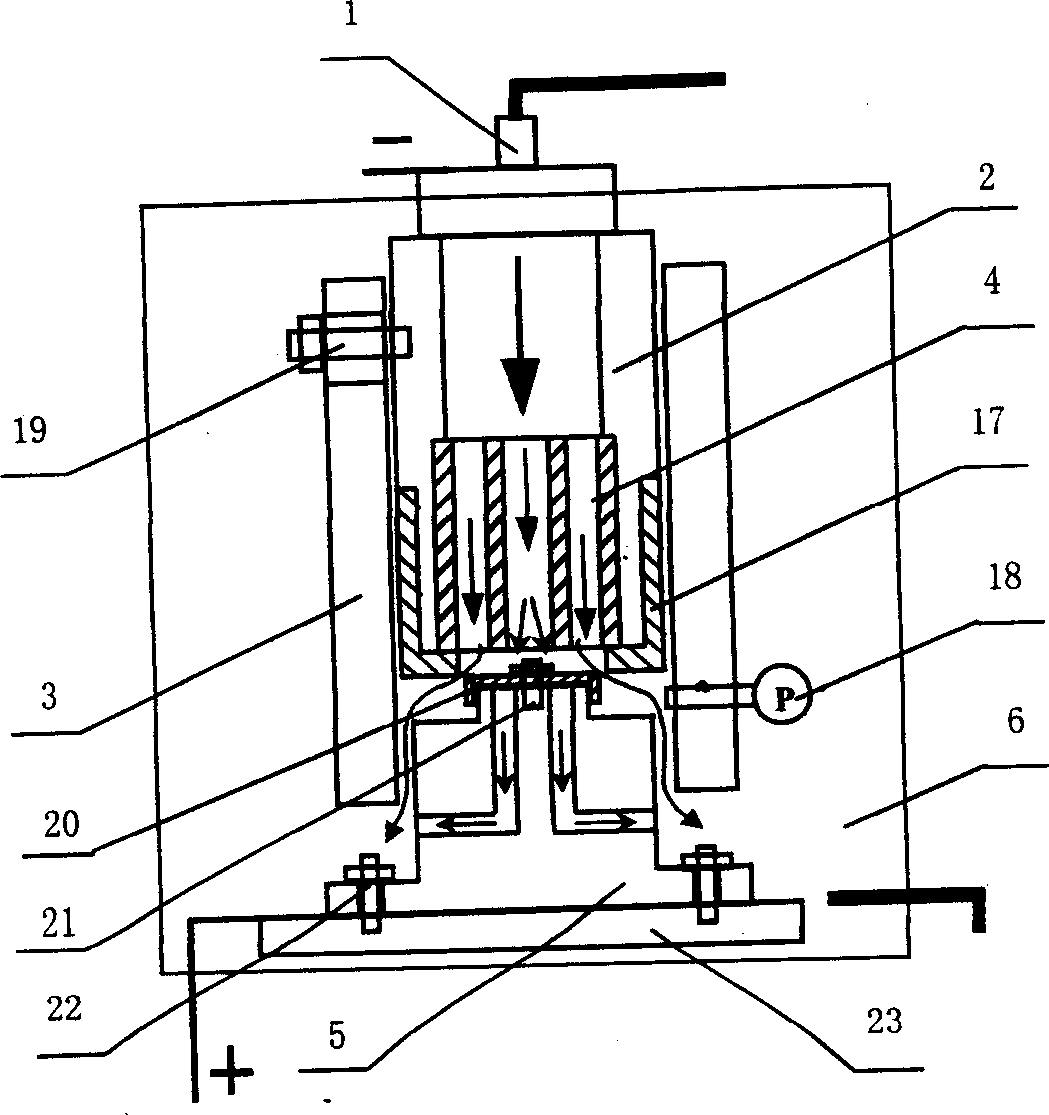

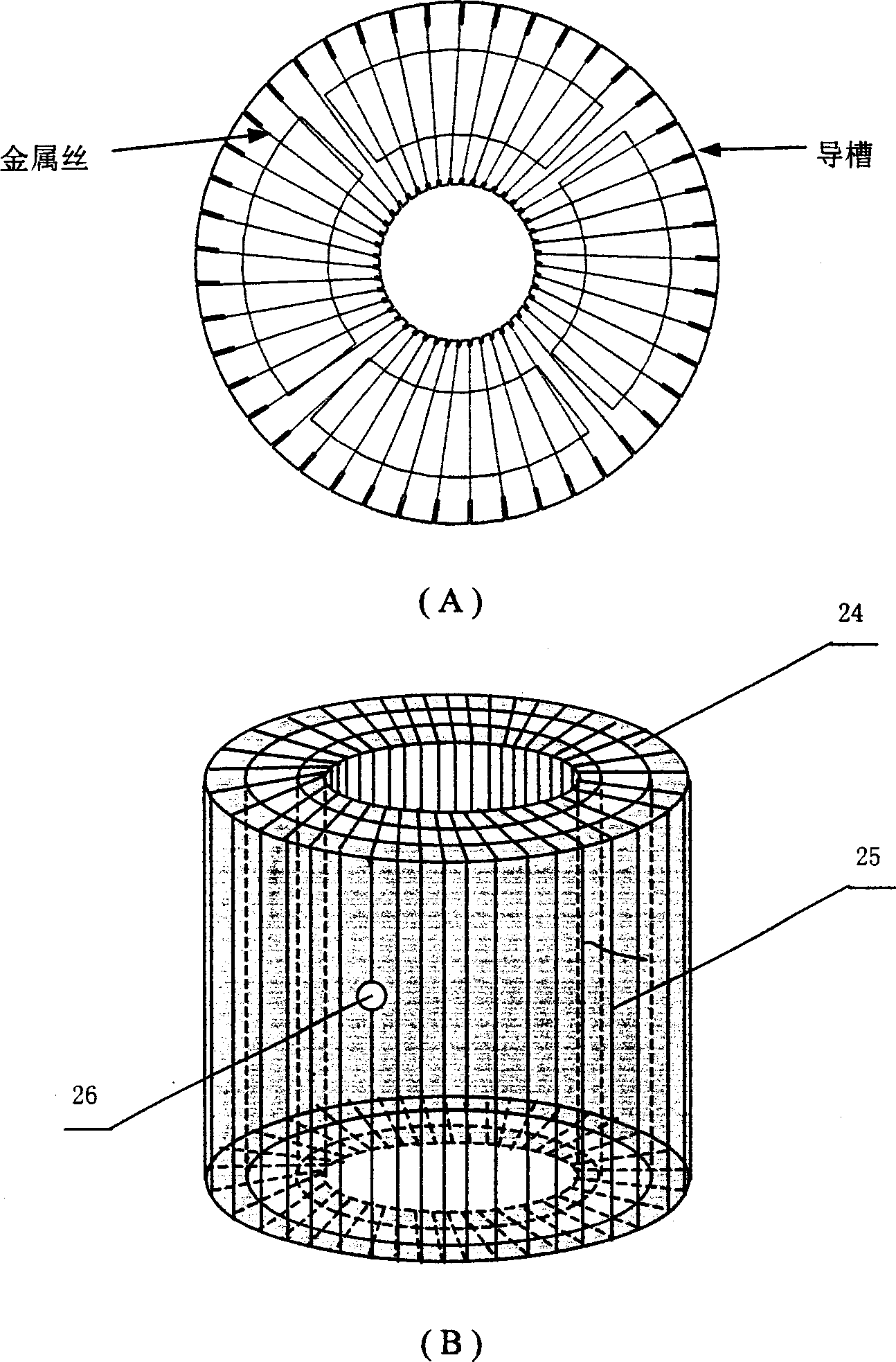

[0020] Implementation of the present invention - "micro-slot electrolytic machining process" device, such as figure 1 As shown, the device includes an electrolyte temperature controller 12, a heater 13 controlled by the temperature controller 12 is placed in the electrolyte in the liquid storage tank 11, a control device 14 connected to a power supply 15 is connected to a transmission device 16, and is connected to the storage tank 11. The electrolyte circulation system composed of the magnetic pump 10 connected to the liquid tank 11, the filter 9, the overflow valve 8, and the ball valve 7 is connected to the working chamber 6, and its characteristic is that the outlet pressure adjustment sleeve 3 of the processing area is fixed to the tool electrode. On the mounting base 2, the wire-wound tool electrode 4 placed in the tool electrode mounting base 2 is connected to the transmission device 16 through the electrode feed shaft 1 and the workpiece mounting base 5 placed at the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com