Electromachining method for preventing electrochemical dispersion corrosion

A stray corrosion and electrochemical technology, applied in electric machining equipment, electrochemical machining equipment, metal machining equipment, etc., can solve the problems of stray corrosion in the non-machined area of the bottom end face of the electrode, reduction of workpiece machining accuracy and surface quality, etc. Achieve the effect of reducing stray corrosion, improving surface quality and forming accuracy, and reducing movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0012] The method for preventing electrochemical stray corrosion in electrical machining provided by the invention comprises the following steps:

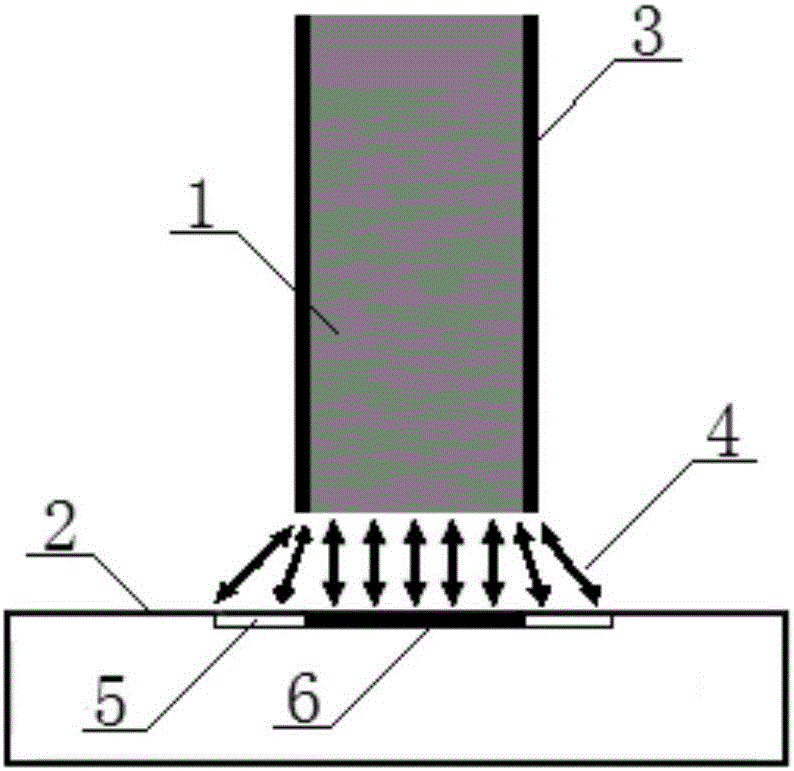

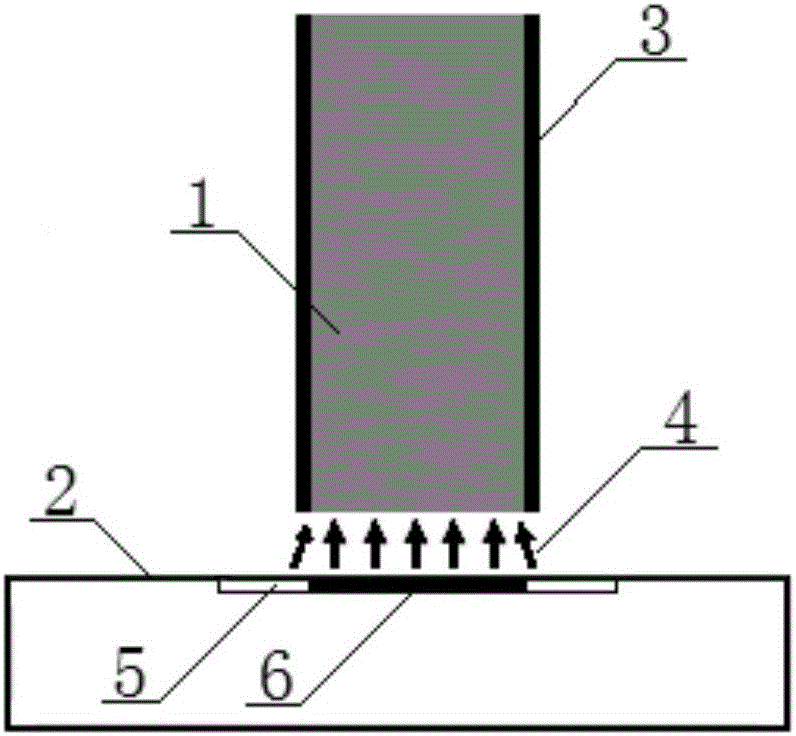

[0013] 1) if figure 1 As shown, the side of the tool electrode 1 is provided with a circle of insulating film layer 3, the tool electrode 1 is fixed on the main shaft of the existing machine tool, the workpiece 2 to be processed is fixed in the electrolytic cell of the machine tool table, the tool electrode 1 and the workpiece 2 Connect the negative pole and the positive pole of the power supply respectively to form a loop. A current sensor for real-time collection of the loop current is set on the loop, and the current sensor sends the collected current value to the existing controller in real time;

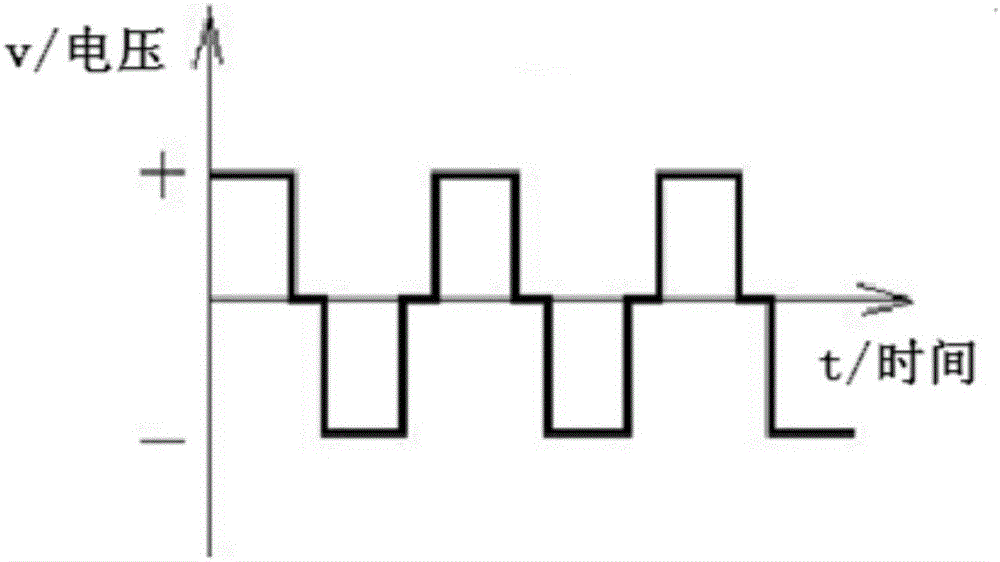

[0014] 2) The tool electrode 1 reaches the initial position (starting position) of the machining under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com