Production process for reel type hologram pattern paper, hologram pattern paper and system

A production process and hologram technology, which are applied in the field of holographic pattern paper and systems to achieve high reproduction accuracy, increased production cost and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

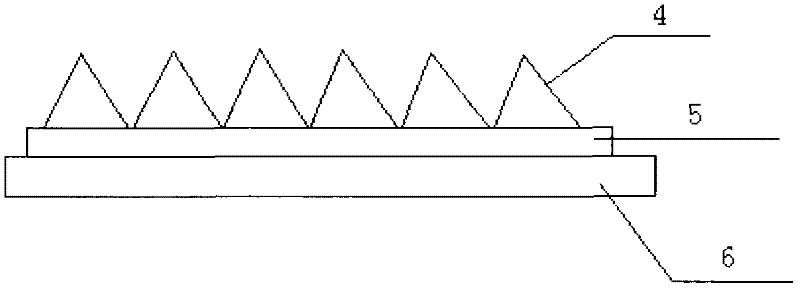

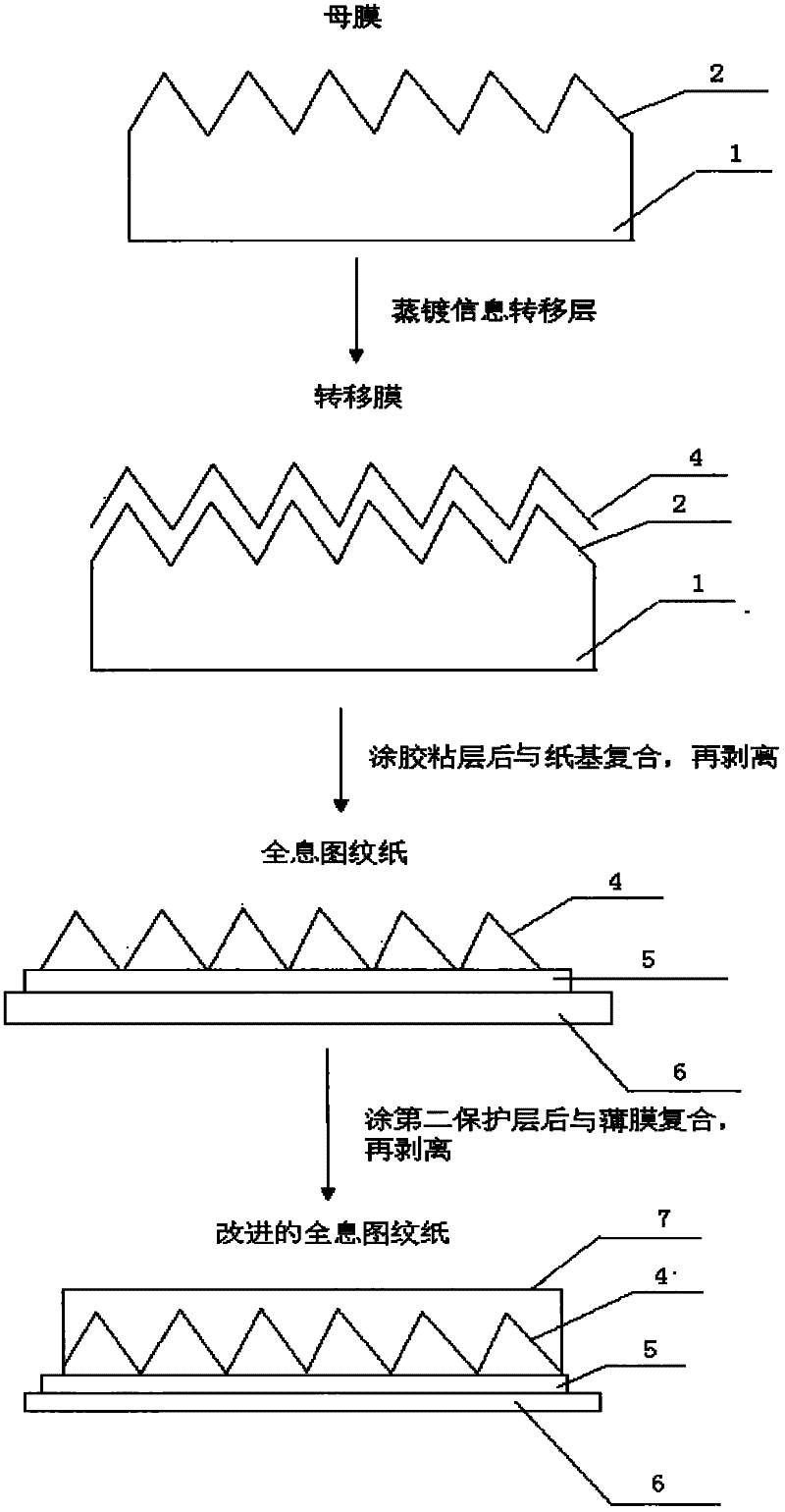

Image

Examples

Embodiment 1

[0048] The evaporation thickness of the information transfer layer is 50 angstroms, and the evaporation process: vacuum degree 10 -2 Millibar, speed 60m / min; UV resin layer composite process: dry coating amount of UV resin to 0.5g, working speed 20m / min; acrylic resin is coated with a coating machine to a wet weight of 1g / m 2 , 80 ℃ drying, drying time 10 seconds, operating speed 20m / min.

Embodiment 2

[0050] The evaporation thickness of the information transfer layer is 500 angstroms, and the evaporation process: vacuum degree 10 -3 Millibar, speed 500m / min; UV resin layer composite process: UV resin dry coating amount to 20 grams, operating speed 100 m / min; acrylic resin is coated with a coating machine to a wet weight of 10 g / m2, and dried at 150 ° C. The drying time is 30 seconds, and the working speed is 100m / min.

Embodiment 3

[0052] The evaporation thickness of the information transfer layer is 1000 angstroms, and the evaporation process: vacuum degree 10 -3 Millibar, speed 1000m / min; UV resin layer composite process: UV resin dry coating amount to 50 grams, operating speed 150 m / min; acrylic resin is coated with a coating machine to a wet weight of 20 grams / m 2 , 200 ℃ drying, drying time 60 seconds, operating speed 150m / min.

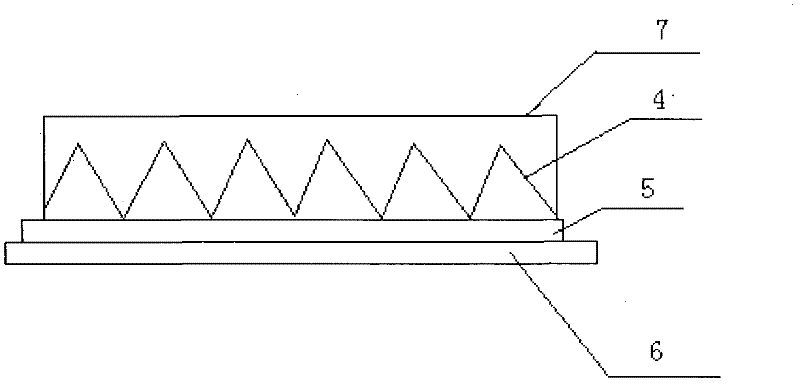

[0053] The second group of embodiments (4-6)

[0054] The difference from the first group of embodiments is that the information transfer layer is made of metal aluminum; the second protective layer is made of polyurethane resin; the holographic pattern paper structure: paper base, UV resin layer, aluminum layer, and polyurethane resin layer.

[0055] The third group of embodiments (7-9)

[0056] The difference from the first group of embodiments is that the information transfer layer is made of silicon oxide; the second protective layer is made of epoxy resin; the hologr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com