High-precision copying method of carbon fiber composite space optical mirror plane

A technology of composite materials and space optics, which is applied in the field of high-precision replication of carbon fiber composite material space optics mirrors, to achieve high replication accuracy, high repeatability of mirror surface quality, and the effect of expanding applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be specifically described below.

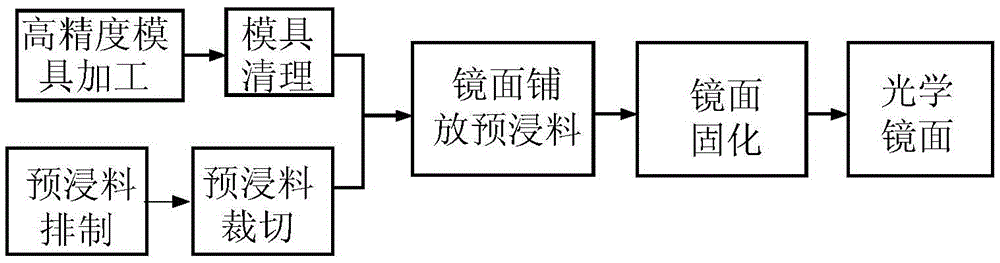

[0025] The present invention is a carbon fiber composite material space optical mirror high-precision replication technology, the specific steps are:

[0026] 1) Duplicate mold design and production

[0027] According to the structural characteristics and surface precision requirements of the optical mirror surface, high-precision stainless steel molds are processed by high-precision grinding and polishing technology on the working surface of the stainless steel mold blank. The surface precision of the mold is PV=1μm, RMS=0.1μm, which meets the optical mirror surface Accuracy requirements for replicating molds.

[0028] 2) Design of prepreg parameters and mirror layup sequence

[0029] According to the mechanical performance requirements of the optical mirror, especially the structural rigidity, the lamination sequence of the mirror is designed by using the method of numerical simulation analysis and experi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com