A laser holographic anti-counterfeiting film

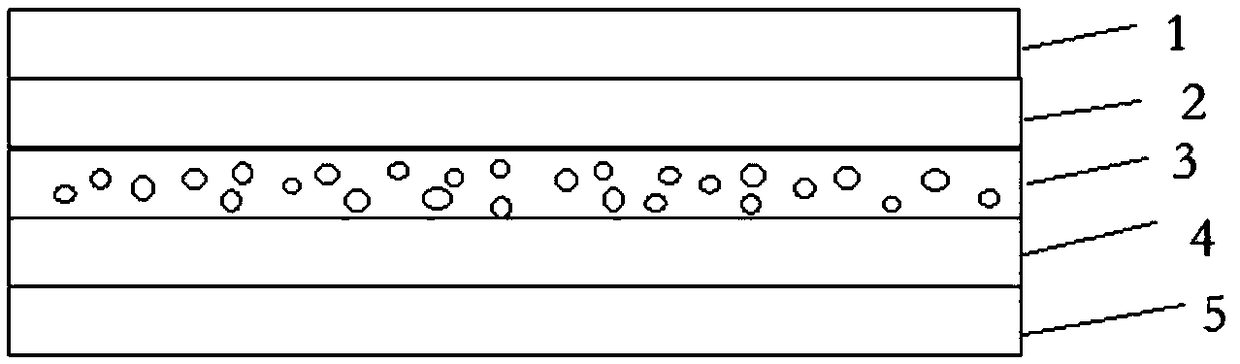

A laser holography and anti-counterfeiting film technology, which is applied in information-bearing cards, printing and other directions, can solve the problems of poor wear resistance, heat distortion, and difficult anti-counterfeiting film, so as to improve process efficiency and operation difficulty, and the overall structure is compact and easy to process. effect made

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Coat the release layer slurry (prepared by oxidized polyethylene wax and toluene at a weight ratio of 1:99.5) on a PET base film with a thickness of 19 microns by an anilox roller coater, and then at 80-150°C, 100m / min speed coating.

[0031] Next, coat the information layer on the above-mentioned release layer, specifically, coat at 80-150° C. at 80 m / min to obtain an information layer with a thickness of 5 microns. Wherein, the above-mentioned information layer is an epoxy resin layer in which the curing agent is coated in the microcapsule body: the epoxy resin can be epoxy resin E-20, which contains 1.7wt% toluene-2,4-diisocyanate, 2.4wt% %2-methylimidazole, 5.4%wt E-44 epoxy resin, 90.5wt% epoxy resin; the overall size of the microcapsule body is 0.8 micron, and its capsule wall is made up of isocyanate, and its thickness is 0.4 micron, and its The internally dispersed capsule core is selected to be composed of adipic acid hydrazide as the heating curing agent, an...

Embodiment 2

[0035] Coat the release layer slurry (1wt% emulsified wax) on the PET base film with a thickness of 12 microns by an anilox roller coater, and then coat at 80-150°C at a speed of 100m / min to obtain a thickness of 0.08 microns release layer.

[0036] Next, coat the information layer on the release layer, specifically at 80-150° C., 80 m / min to obtain an information layer with a thickness of 2 micrometers. Wherein, the above-mentioned information layer is an epoxy resin layer in which the curing agent is coated in the microcapsule body: the epoxy resin can be epoxy resin E-20, which contains 1.7wt% toluene-2,4-diisocyanate, 2.4wt% %2-methylimidazole, 5.4%wt E-44 epoxy resin, 90.5wt% epoxy resin; the overall size of the microcapsule body is 1 micron, and its capsule wall is made up of isocyanate, and its thickness is 0.2 micron, and its The internally dispersed capsule core is selected to use salicylic acid hydrazide as the heating and curing agent, and the weight ratio between th...

Embodiment 3

[0040] Coat the release layer slurry (prepared by oxidized polyethylene wax and toluene at a weight ratio of 1:99.5) on a PET base film with a thickness of 50 microns by an anilox roller coater, and then at 80-150°C, 100m / min speed coating.

[0041] Next, coat the information layer on the above-mentioned release layer, specifically, coat at 80-150° C. at 80 m / min to obtain an information layer with a thickness of 6.5 microns. Wherein, the above-mentioned information layer is an epoxy resin layer in which the curing agent is coated in the microcapsule body: the epoxy resin can be epoxy resin E-20, which contains 1.7wt% toluene-2,4-diisocyanate, 2.4wt% %2-methylimidazole, 5.4%wt E-44 epoxy resin, 90.5wt% epoxy resin; the overall size of the microcapsule body is 0.8 micron, and its capsule wall is made up of isocyanate, and its thickness is 0.6 micron, and its The inner dispersing capsule core is selected to be composed of p-hydroxybenzoic acid hydrazide as the heating curing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com