Method for preparing GaAs micro/nono optical element

A technology of optical elements and optical arrays, applied in optical elements, optics, microstructure technology, etc., can solve the problems of expensive and difficult, high processing costs, no low-cost micro/nano optical element processing methods, etc., and achieve high replication accuracy , The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

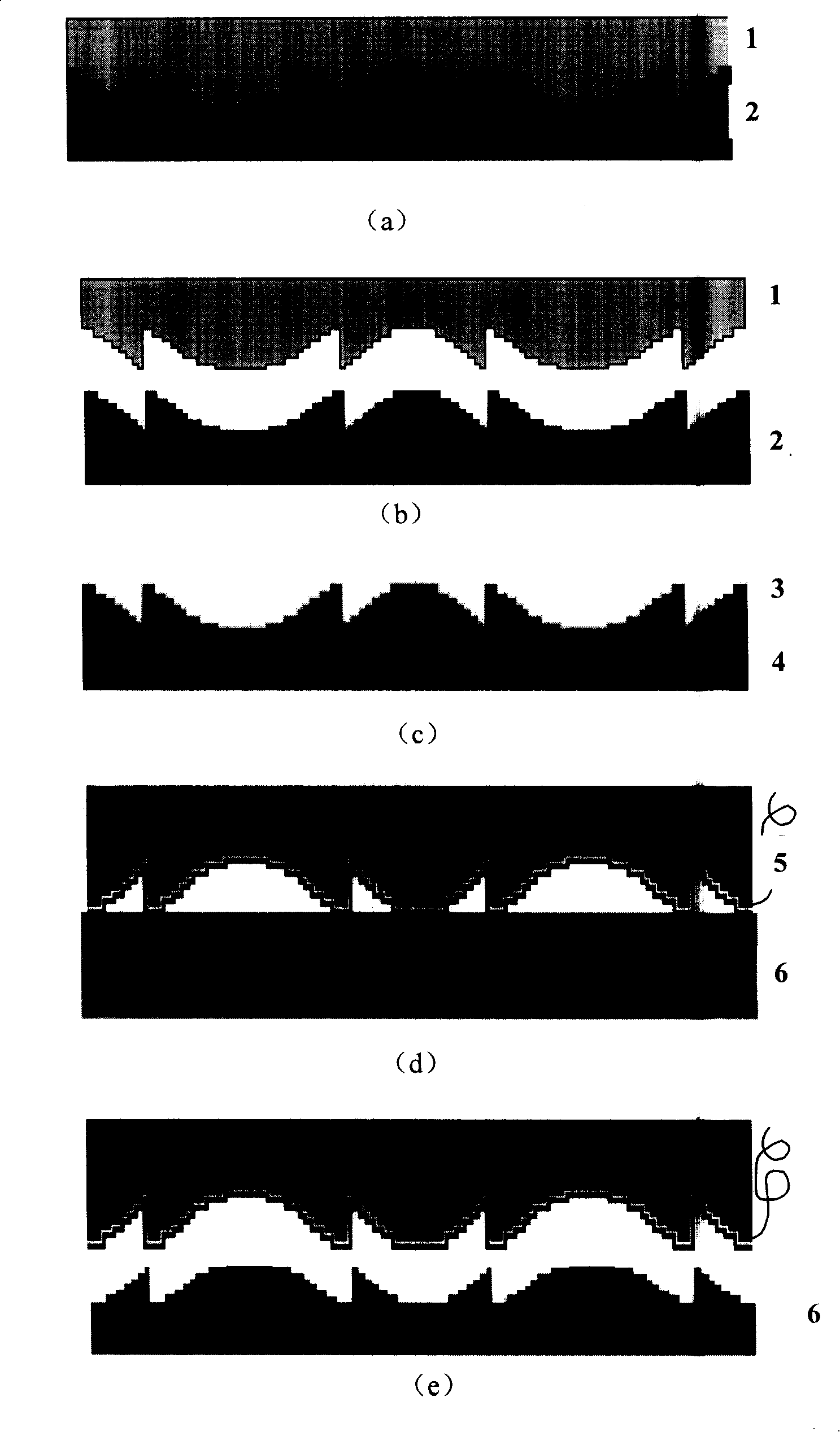

[0036] figure 1 A schematic diagram of the processing technology of Example 1 of the present invention is given.

[0037] figure 1 a is the hot embossing process, the polymer material is PMMA 2 (polymethyl methacrylate) and the quartz optical element master 1 is placed in the hot embossing device, the selected glass transition temperature (T g ) temperature is 100°C. PMMA 2 has a thickness of 1mm and an area of 2cm 2 ,use figure 2 The shown hot embossing device is heated up to the glass transition temperature (T g ) above (generally controlled at 135°C), and then apply a pressure of 4 to 10 MPa for replication.

[0038] figure 1 B is the demoulding and separation process after hot pressing replication. After the hot pressed PMMA sheet 2 is separated from the quartz optical element master plate 1, the PMMA sheet 2 also needs to be degreased. 3 PO 4 50g / L+Na 2 CO 3 25g / L+NaOH 20g / L for degreasing treatment, the deoiling temperature is 85°C, and the time is 2.5h. ...

Embodiment 2-6

[0047] The specific operation steps of Examples 2-6 are the same as those of Example 1, and the specific composition of the solution is shown in Table 1, wherein the etching effect "+" is good.

[0048] Table 1

[0049] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com