Method for inspecting translucent article

An inspection method and technology of light transmittance, which is applied to the original parts used for photomechanical processing, optics, glass molding, etc., can solve the problems of reduced copying accuracy, reduced transmittance, optical unevenness, etc., to prevent surface damage Damage, damage prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

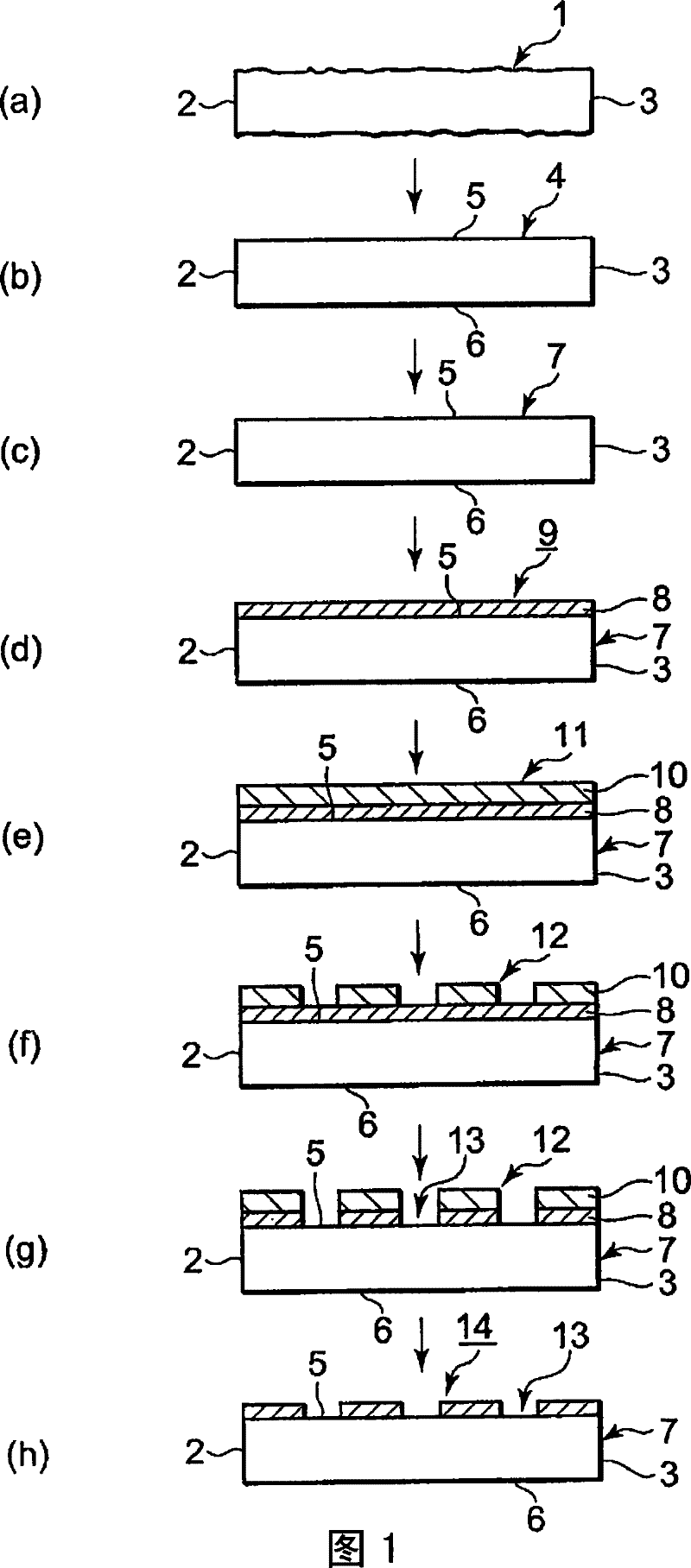

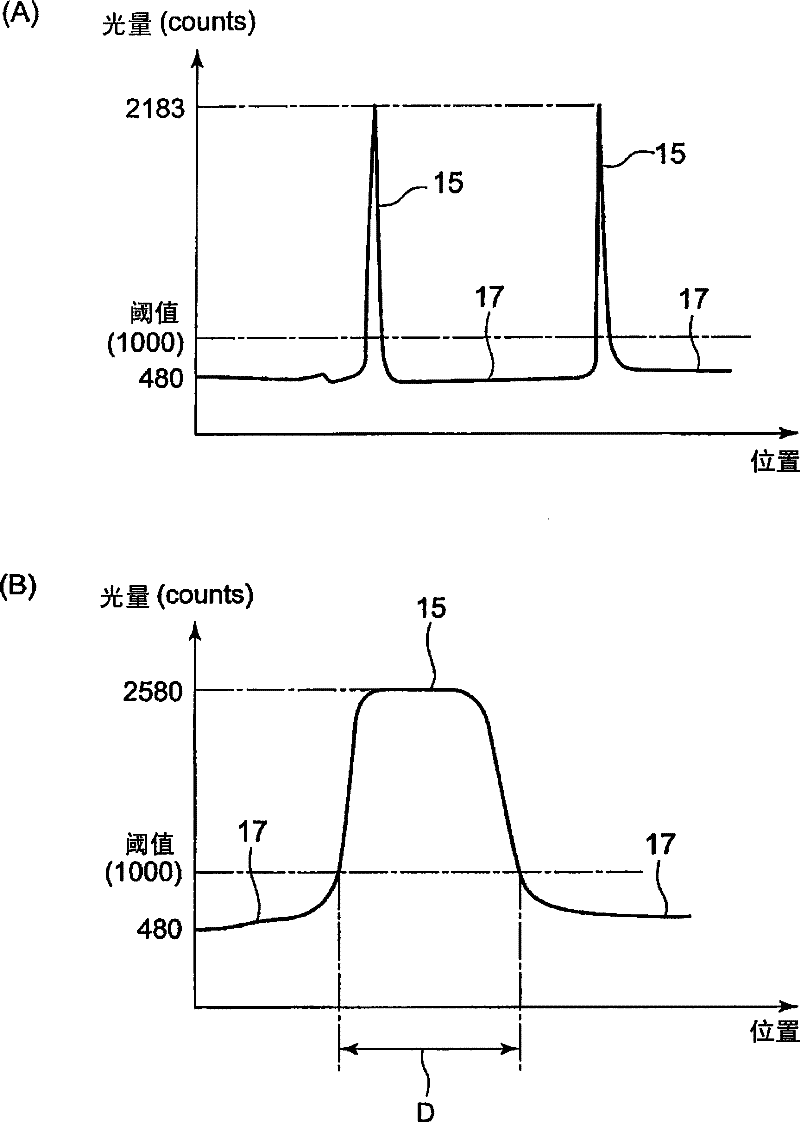

[0177] Prepare 10 synthetic quartz glass substrates in which a synthetic quartz glass base material (synthetic quartz glass blank) produced from silicon tetrachloride etc. The synthetic quartz glass plate obtained in mm was subjected to shape processing and chamfering processing, and an ArF excimer laser (wavelength: 193 nm) as inspection light was introduced into the end face (the side perpendicular to the main surface on which the thin film was formed, and between the main surface and the main surface) The surface roughness of the chamfered face formed between the side faces) is 0.5 μm or less at the maximum height Rmax. In addition, since the main surface of the prepared synthetic quartz glass substrate was not mirror-polished or precision-polished, it was frosted glass.

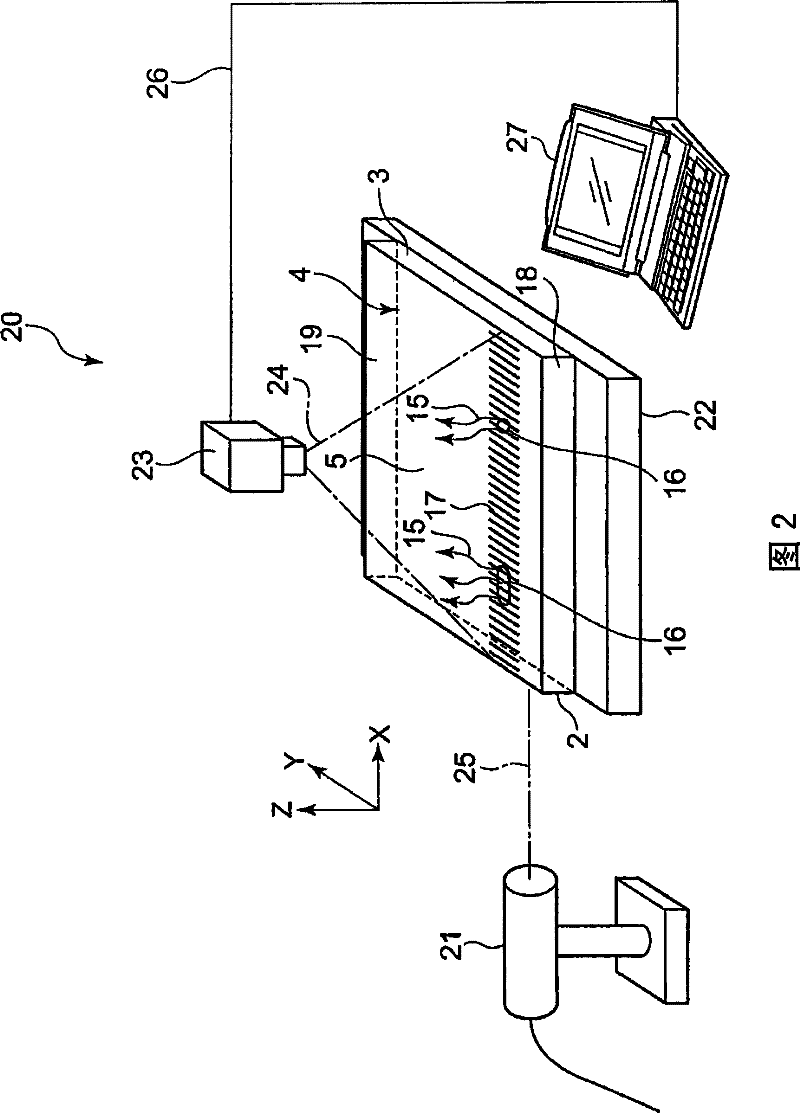

[0178] Next, using the defect inspection device described in the above-mentioned embodiment, a beam shape larger than the thickness of the synthetic quartz glass substrate is introduced into the end surfa...

Embodiment 2

[0192] In the above-mentioned Example 1, inspection of internal defects used a defect inspection device installed in an atmosphere of clean air circulation (ISO class 4, using a chemical filter) to inspect internal defects of synthetic quartz glass substrates, and in addition, with The inspection method of the synthetic quartz glass substrate was carried out in the same manner as in Example 1 above, and the main surface was further precisely polished to obtain a glass substrate for a mask blank. As a result, it is possible to inspect the internal defects of the synthetic quartz glass substrate without damaging the end face to which the ArF excimer laser is introduced, and to select a synthetic quartz glass substrate in which light is not locally generated as fluorescence. Using the selected synthetic quartz glass substrate, the main surface was precisely ground to produce a glass substrate for a mask blank, and further, a halftone phase shift mask and a photomask were produced,...

Embodiment 3

[0194] In the above-mentioned Example 1, the introduction surface where the ArF excimer laser needs to be introduced is formed on the synthetic quartz glass base material (synthetic quartz glass blank) produced by using silicon tetrachloride or the like as a starting material, and ArF is introduced from the introduction surface. Excimer laser, which inspects internal defects inside the base material of synthetic quartz glass. In addition, the introduction surface is formed by partially mirror-polishing the surface of the synthetic silica glass base material so that the size is larger than the beam shape of the ArF excimer laser beam and becomes a mirror state.

[0195] When ArF excimer laser light was introduced into a synthetic quartz glass base material, a region not locally generated as fluorescence was specified, and an exposure device using ArF excimer laser light as exposure light was produced from a block of synthetic quartz glass cut into only the specific region (step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com