Melt direct writing process based micro-channel chip manufacturing processing system and processing method

A processing system and micro-channel technology, applied in the field of micro-fluidic device processing system, can solve the problems of micro-fluidic chip line width limitation, time-consuming and expensive, complicated manufacturing method, etc., to improve aspect ratio, reduce Width, the effect of improving copy accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

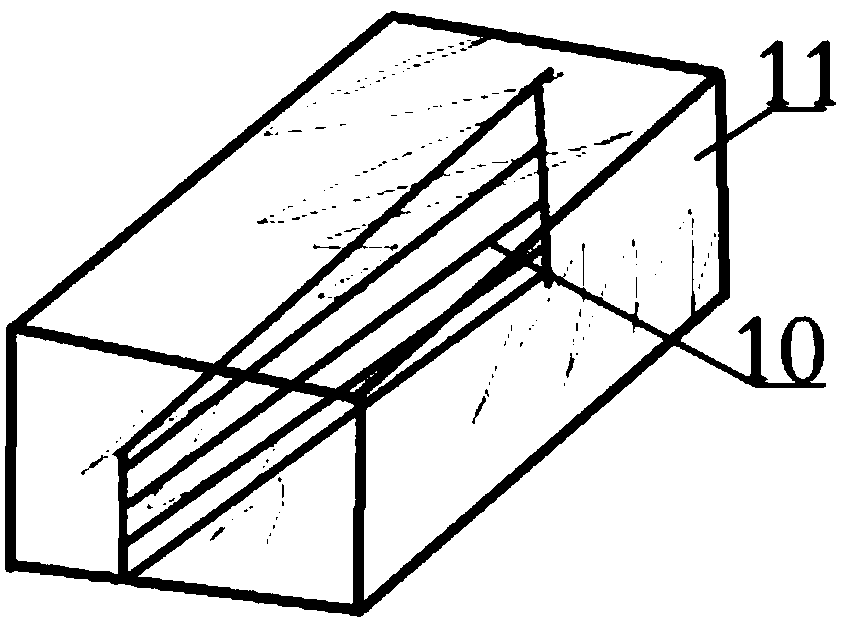

[0023] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

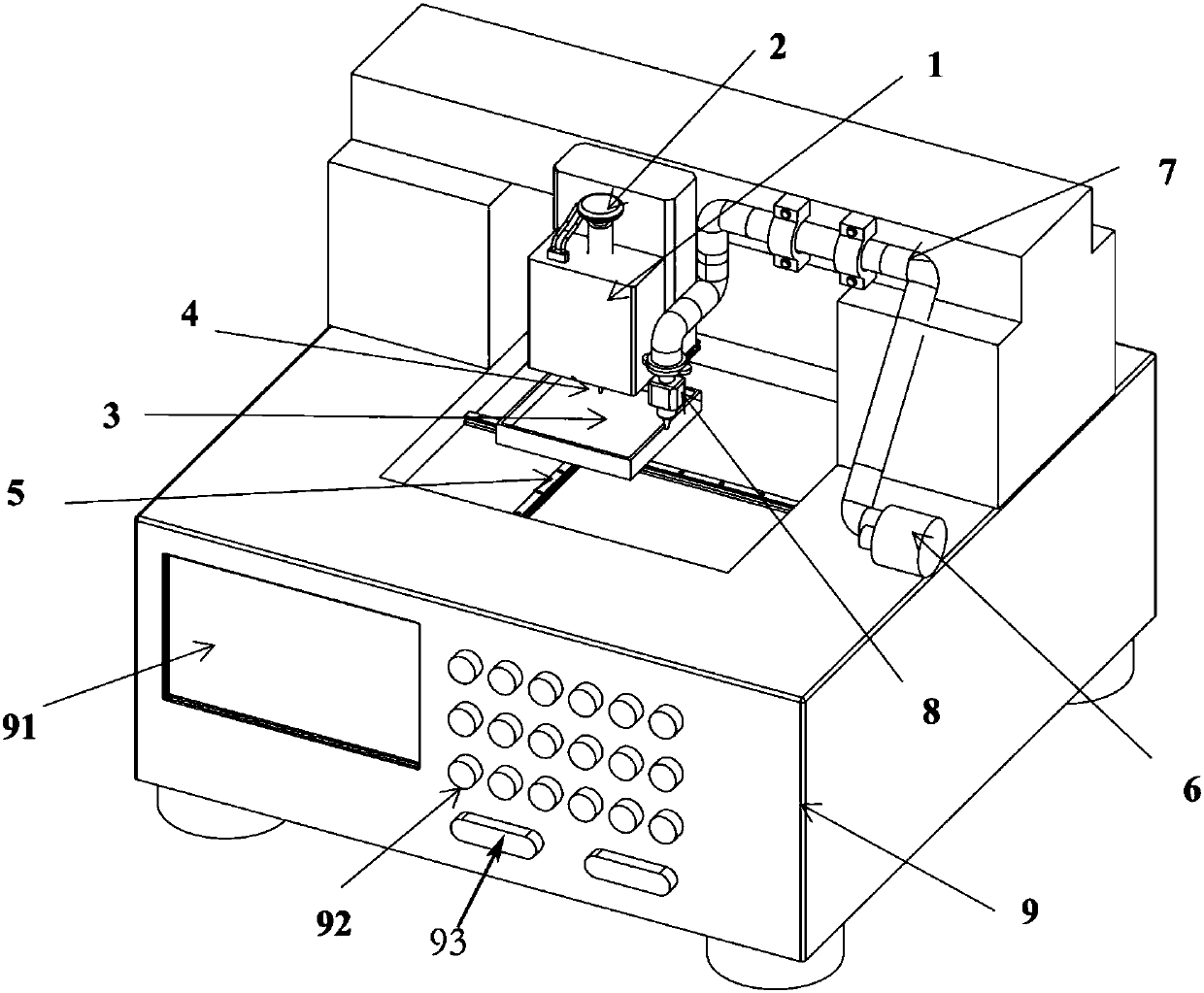

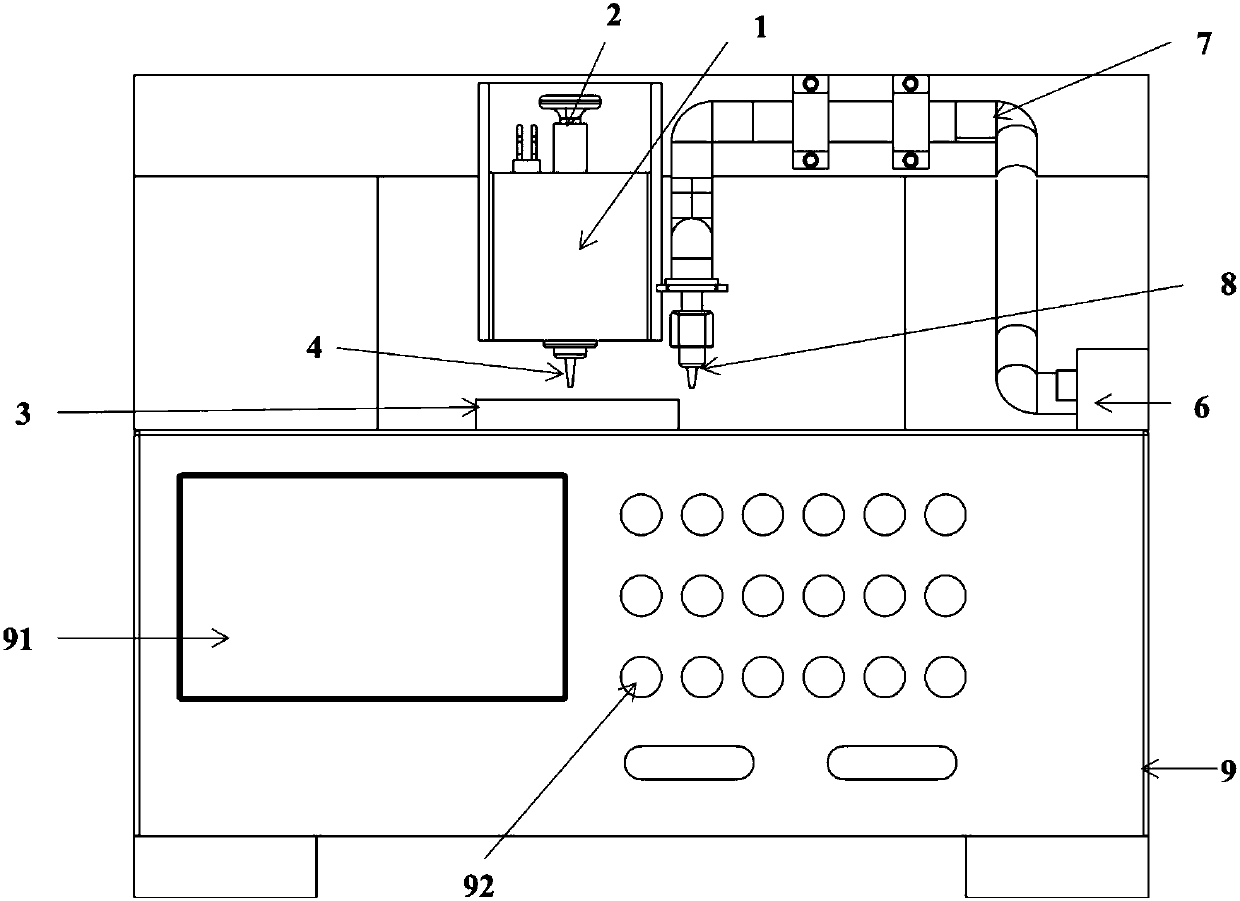

[0024] Such as figure 1 , figure 2 As shown, a processing system for fabricating microfluidic chips based on the melt direct writing process, including a melt direct writing deposition device, a curing agent liquid addition device and a control device, wherein,

[0025] Described control device comprises control box 9, is provided with microprocessor in the described control box 9, is provided with display screen 91, acquisition switch 93 and function key 92 on the casing of described control box 9, and described function key 92 and The signal input end of the microprocessor is connected, and the display screen 91 is connected with the signal output end of the microprocessor (FPGA processor).

[0026] The melt direct writing deposition device is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com