Method for manufacturing larger-area anti-adsorption surface with emulational shark skin appearance

A production method, shark skin technology, applied in the field of bionics manufacturing, can solve the problems of unsuitable practical application, complex process, high cost, etc., and achieve the effect of good protection, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

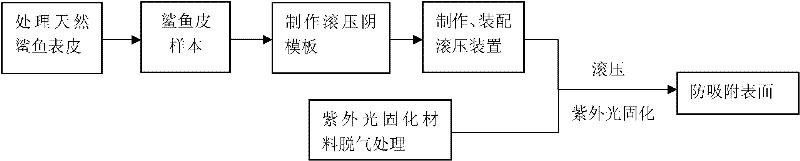

[0043] Such as figure 1 , the present invention has a large-area production method of an anti-adsorption surface with a realistic shark skin appearance, and the specific steps of the method are as follows:

[0044] Step 1: Prepare rolling negative template device

[0045] (A) cut off the shark skin 200 * 100mm, rinse with clear water and deionized water 3-5 times respectively, and finish the cleaning of the shark skin;

[0046] (B) Soak the cleaned shark skin completely in 2.5% glutaraldehyde solution, place it in a constant temperature environment at 4°C for 7 hours, and complete the fixation of the shark skin;

[0047] (C) Rinse the fixed shark skin with 4% phosphate buffer solution for 10 minutes, then rinse it with water and deionized water for 5 times, then soak it in 50% ethanol for 15 minutes, 75% ethanol for 15 minutes, and 95% etha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com