Roll-type hologram paper manufacturing process, hologram paper and system

A production process and hologram technology, which is applied in the directions of synthetic resin layered products, layered products, chemical instruments and methods, etc., to achieve the effect of good effect, reduced production cost and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

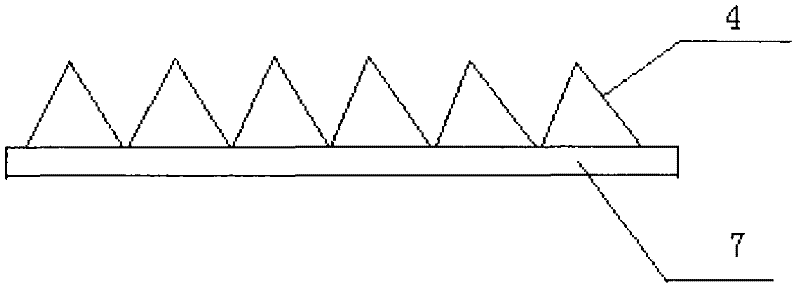

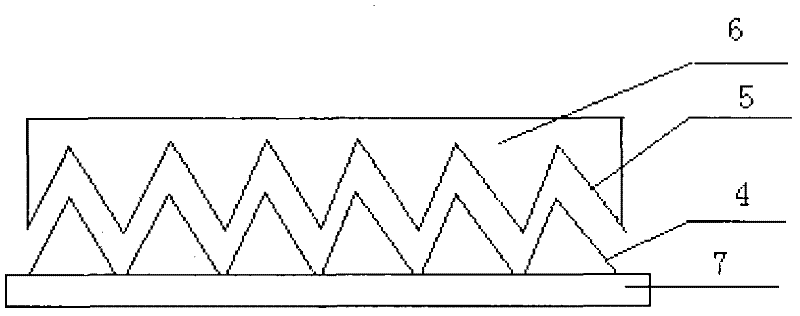

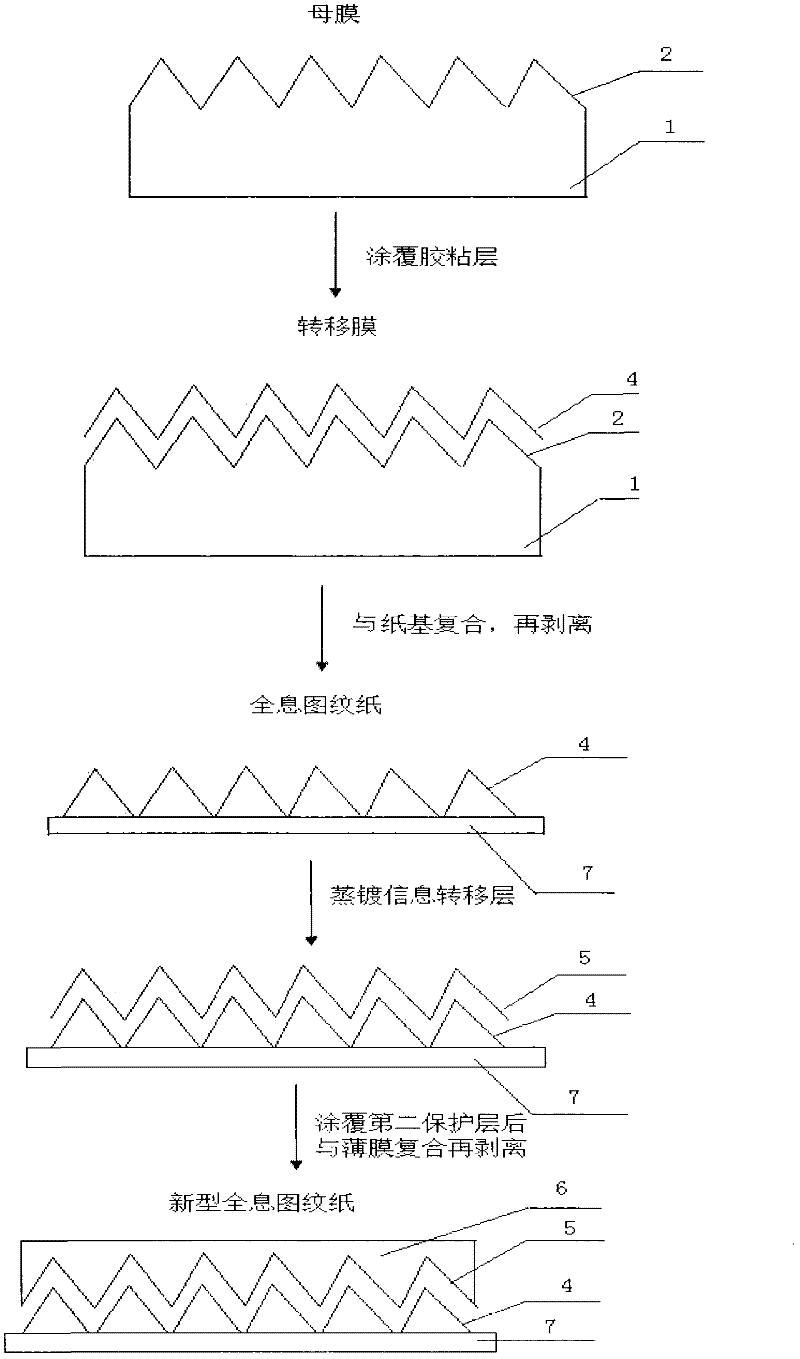

Image

Examples

Embodiment 1

[0049] UV resin layer composite process: UV resin dry coating amount to 0.5 grams, operating speed 20 m / min; information transfer layer evaporation thickness 50 angstroms, evaporation process: vacuum degree 10 -2 Millibar, speed 60m / min; acrylic resin is applied with a coating machine to a wet weight of 1 g / m 2 , 80 ℃ drying, drying time 10 seconds, operating speed 20m / min.

Embodiment 2

[0051] UV resin layer composite process: UV resin dry coating amount to 20 grams, operating speed 100 m / min information transfer layer evaporation thickness 500 angstroms, evaporation process: vacuum degree 10 -3 Millibar, speed 500m / min;; Acrylic resin is coated with a coating machine to a moisture content of 10 g / m2, dried at 150°C, drying time is 30 seconds, and the operating speed is 100m / min.

Embodiment 3

[0053] UV resin layer composite process: UV resin dry coating amount to 50 grams, operating speed 150 m / min; information transfer layer evaporation thickness 1000 angstroms, evaporation process: vacuum degree 10 -3 Millibar, speed 1000m / min; acrylic resin is applied with a coating machine to a wet weight of 20 g / m 2 , 200 ℃ drying, drying time 60 seconds, operating speed 150m / min.

[0054] The second group of embodiments (4-6)

[0055] The difference from the first group of embodiments is that the information transfer layer is made of metal aluminum; the second protective layer is made of polyurethane resin; the holographic pattern paper structure: paper base, UV resin layer, aluminum layer, and polyurethane resin layer.

[0056] The third group of embodiments (7-9)

[0057] The difference from the first group of embodiments is that the information transfer layer is made of silicon oxide; the second protective layer is made of epoxy resin; the holographic pattern paper struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com