Manufacturing method of flexible thermo-electric device and manufactured flexible thermo-electric device

A thermoelectric device and device technology, applied in the field of thermoelectric power generation devices, can solve the problems of poor controllability, non-flexible devices, long material preparation cycle, etc., and achieve the effects of releasing thermal stress, broadening application occasions, and bending at a large angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to specific embodiments and accompanying drawings. However, those skilled in the art know that the present invention is not limited to the accompanying drawings and the following embodiments.

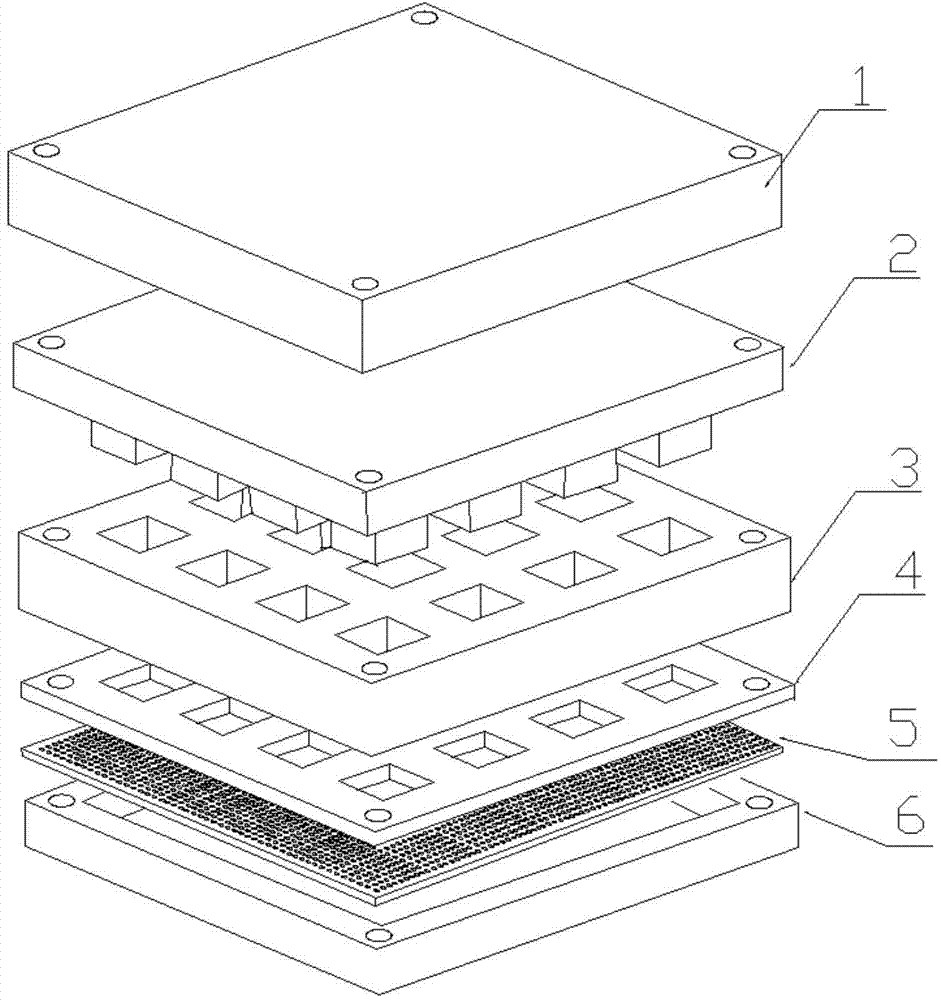

[0028] like figure 1 , 2 , 3, 4, and 5, the preparation method of the flexible thermoelectric device proposed by the present invention includes the following steps:

[0029] (1) According to the application requirements, the size of P-N type semiconductor particles is 4.5×4.5×2.5 (mm), and the thermoelectric device with 49 pairs of P-N semiconductor particles is designed and cut.

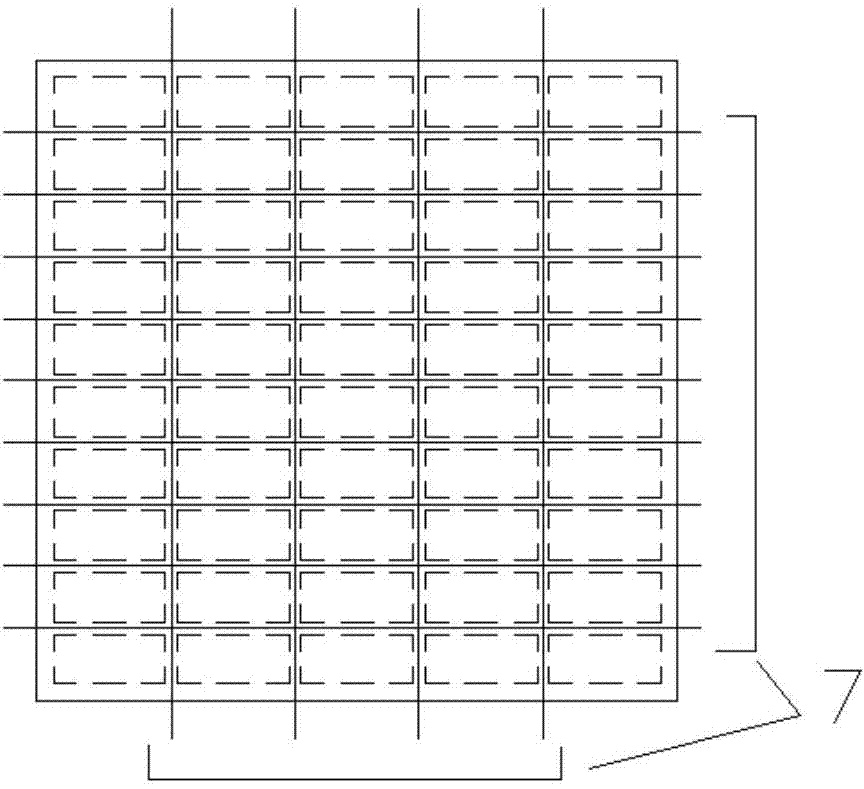

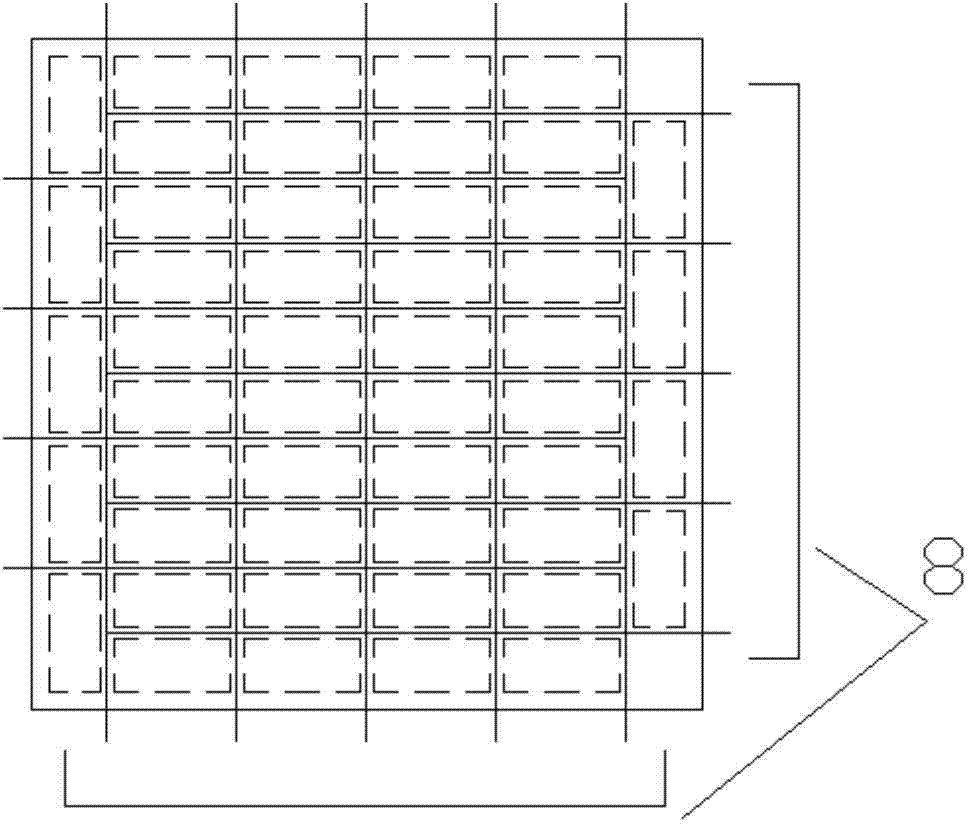

[0030] (2) The copper wire mesh 5 is flatly fixed on the lower substrate 6 of the mold, the mask 4 is covered, and the solder "scratch coating" operation on the A side of the device is performed.

[0031] (3) Remove the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com