A Vertical Rectangular Cooling Furnace for Sintered Ore

A cooling furnace and sintering ore technology, applied in the field of iron and steel metallurgy sintering, can solve the problems of flue gas temperature recovered from the top of red ore furnace, low efficiency of waste heat recovery and utilization, poor cooling effect of sintering ore, etc. The service life and the effect of improving the wind suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

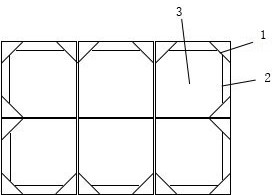

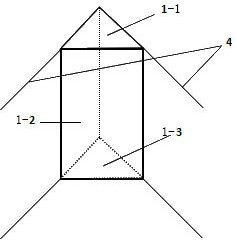

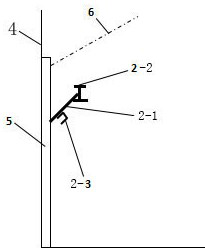

[0022] This example is aimed at the technical transformation of a sinter vertical rectangular cooling furnace in a steel plant. According to the measured data of the wind speed when the furnace is full of material before the transformation, 1) the corner (triangular) area (area of 0.6m2) inside the furnace 2 ~0.7m 2 ) The wind speed is as high as 10m / s or more, so the corner wind suppression device is installed in this area; 2) The wind speed in the surrounding wall area of the furnace (except the corner (triangular) area) reaches 5m / s~10m / s, and the width of this area ( The horizontal projection width to the inner side of the furnace) is 500m~600mm, and the edge effect is obvious, and the side wall wind suppression and diversion device is installed in this area.

[0023] The sinter vertical rectangular cooling furnace of this embodiment is as Figure 1-4 As shown, the corner triangular area in the cooling furnace 3 is provided with a corner wind suppression device 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com