Material distributing and defoaming device of evaporator

An evaporator and dispersing device technology, applied in the field of evaporation and separation equipment, can solve problems such as limitations, and achieve the effects of suppressing escape, avoiding foam, and reducing product loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

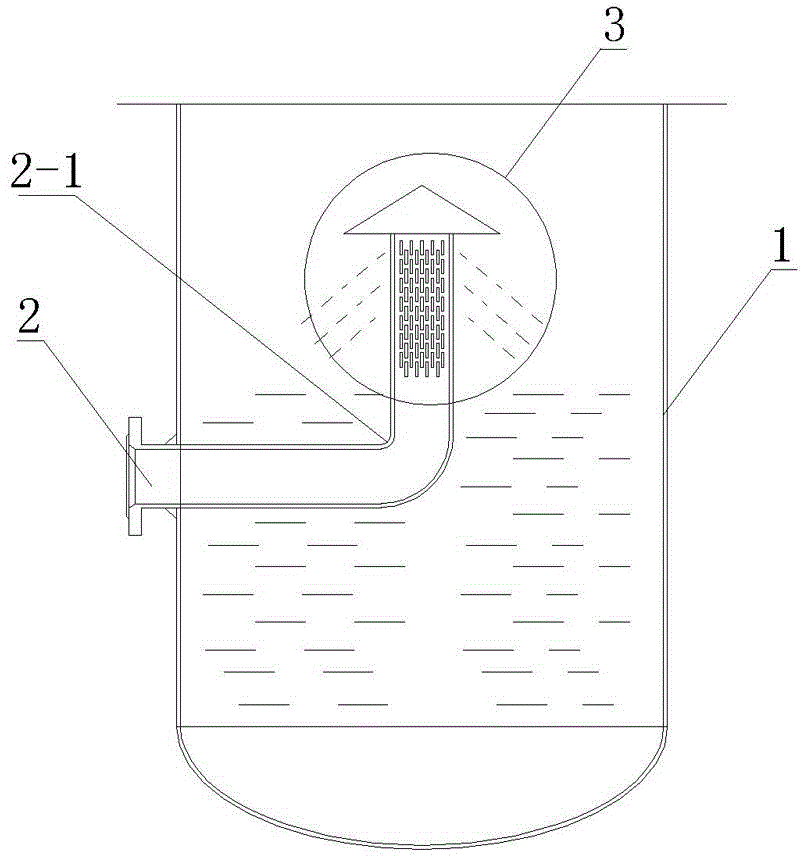

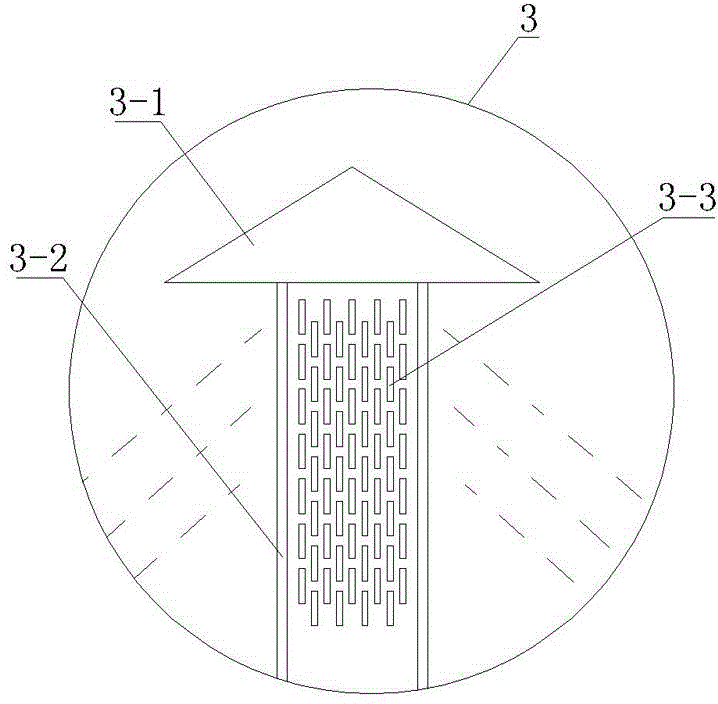

[0017] Embodiment 1: The structure of the evaporator material distribution and defoaming device provided by the present invention is as follows figure 2 and image 3 As shown, it includes a feed pipe 2 pierced on the wall 1 of the evaporator. The feed pipe 2 has an elbow 2-1 on the center line of the evaporator, and the elbow 2-1 is connected with a vertically arranged medium dispersion device. 3 are connected, and the medium dispersing device 3 is fixedly connected by an umbrella-shaped top cover 3-1 and a tubular side wall 3-2, wherein the diameter of the umbrella-shaped top cover 3-1 is 2 times the diameter of the top of the tubular side wall 3-2 times, the rectangular spray holes 3-3 of 4mm*30mm are arranged on the tubular side wall 3-2, wherein the horizontal distance between adjacent spray holes 3-3 in each row of spray holes is equal, and the adjacent two rows of spray holes The shower holes 3-3 are mutually staggered, and the long side of the rectangle is parallel to...

Embodiment 2

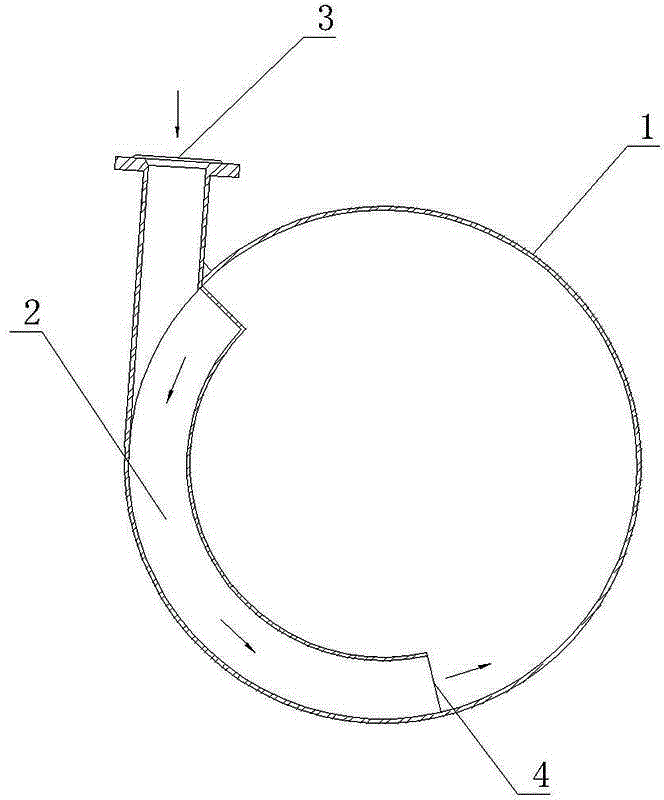

[0019] Embodiment 2: The structure of the evaporator material distribution and defoaming device provided by the present invention is as follows Figure 4 and Figure 5 As shown, the structure is basically the same as that of Example 1, the main difference is that the structure of the medium dispersion device 4 is improved, and also includes the feed pipe 2 pierced on the wall 1 of the evaporator, and the center line of the feed pipe 2 in the evaporator There is an upward right-angle elbow 2-1, and the elbow 2-1 communicates with the vertically arranged medium dispersion device 4. The medium dispersion device 4 is fixedly connected by an umbrella-shaped top cover 4-1 and a tubular side wall 4-2. , wherein the diameter of the umbrella-shaped top cover 4-1 is three times the diameter of the top of the tubular side wall 4-2, the tubular side wall 4-2 is in the shape of a circular platform, the height of the circular platform is 600mm, and the included angle between the busbar and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com