Preparation method of oxidized starch

A technology of oxidized starch and native starch, applied in the field of modified starch, can solve the problems of poor processing performance of oxidized starch, and achieve the effects of good thickening effect, good stability and simplified process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

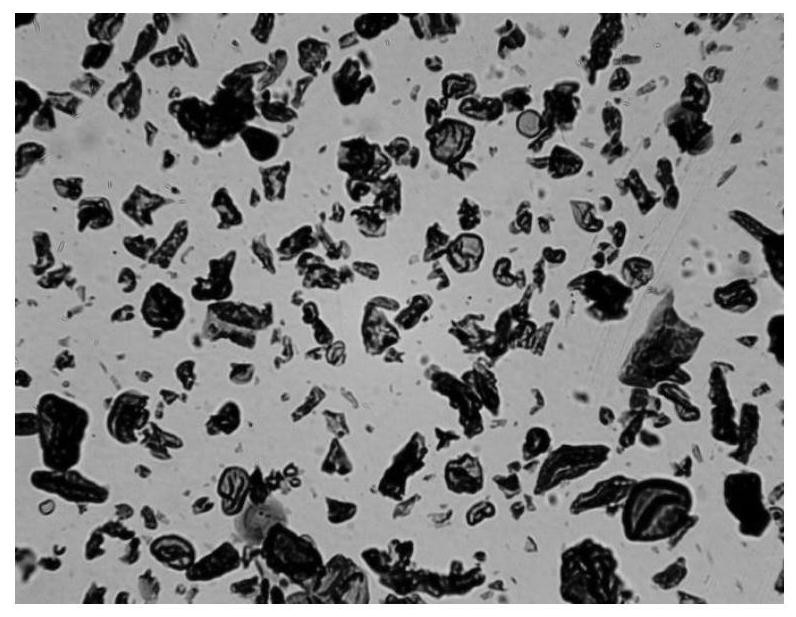

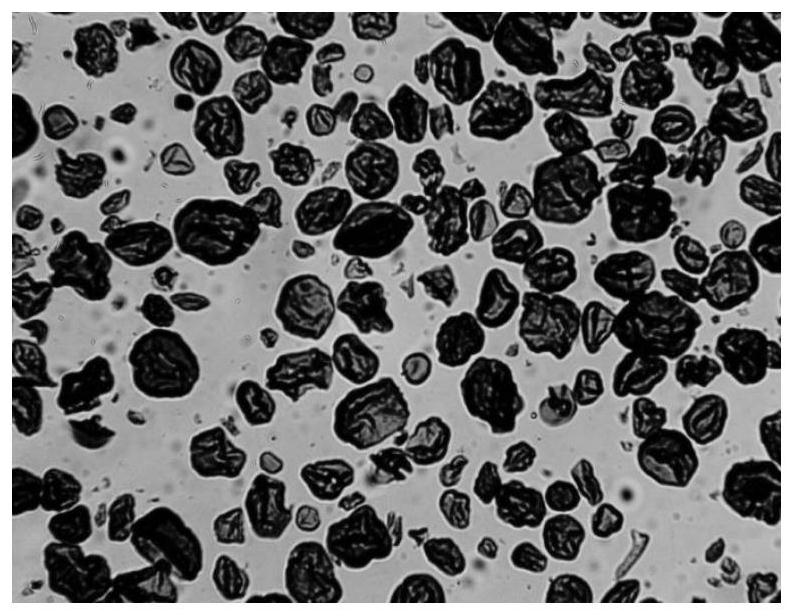

Image

Examples

preparation example Construction

[0029] The invention provides a kind of preparation method of oxidized starch, comprises the steps:

[0030] Mix raw starch and water to prepare starch milk;

[0031] Adjust the pH of starch milk to 5.5-7.0, add protease to carry out enzymatic hydrolysis reaction, the temperature of enzymatic hydrolysis reaction is 30°C-45°C;

[0032] After the enzymatic hydrolysis reaction is finished, an oxidizing agent is added to the obtained reactant to carry out oxidation reaction to prepare oxidized starch.

[0033] The present invention systematically studies the traditional preparation process of oxidized starch and finds that the reason why the traditional preparation process is prone to produce a large amount of foam in the process of preparing oxidized starch is that: since the original starch is natural starch, there are usually protein impurities, protein A large number of foams will appear during the oxidation process of impurities, which will have a more obvious impact on the ...

Embodiment 1

[0063] The present embodiment provides a kind of preparation method of oxidized starch, and the steps are as follows:

[0064] (1) Take 1kg waxy corn starch, add water to prepare starch milk, the mass concentration of waxy corn starch in the starch milk is 35%;

[0065] (2) Warm up the starch milk to 30°C, add 3.0% aqueous sodium hydroxide solution to adjust the pH to 6.6, add 0.05 g of protease, stir for 30 minutes, and carry out enzymatic hydrolysis;

[0066] (3) Adding mass concentration in step (2) enzymolysis reaction garnate is 3.0% sodium hydroxide aqueous solution, adjusts pH to 8.5, drips the periodic acid aqueous solution (mass concentration) after the refrigeration of 0.6% waxy corn starch quality 10%), the dropping time is 40min, then an appropriate amount of 3.0% sodium hydroxide aqueous solution is added to keep the pH at 8.5, and the reaction is carried out at 30°C for 2h;

[0067] (4) Neutralize, wash, dehydrate, dry, pack to obtain the finished product and de...

Embodiment 2

[0069] The present embodiment provides a kind of preparation method of oxidized starch, and the steps are as follows:

[0070] (1) Take 1kg waxy corn starch, add water to prepare starch milk, the mass concentration of waxy corn starch in the starch milk is 35%;

[0071] (2) Warm up the starch milk to 35°C, add 3.0% aqueous sodium hydroxide solution to adjust the pH to 6.6, add 0.05 g of protease, stir for 30 minutes, and carry out enzymatic hydrolysis;

[0072] (3) Adding mass concentration in step (2) enzymolysis reaction garnate is 3.0% sodium hydroxide aqueous solution, adjusts pH to 8.5, drips the periodic acid aqueous solution (mass concentration) after the refrigeration of 0.6% waxy corn starch quality 10%), the dropping time was 40min, and then an appropriate amount of 3.0% sodium hydroxide aqueous solution was added to maintain the pH at 8.5, and the reaction was carried out at 35°C for 2h;

[0073] (4) Neutralize, wash, dehydrate, dry, pack to obtain the finished pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com