VLCC cargo oil tank segmentation and gantry carrying process

A cargo oil tank and process technology, applied to ships and other directions, can solve the problems of prolonging the docking period, increasing the working hours, affecting the ship's docking cycle, etc., and achieving the effect of shortening the cycle, saving the operation time, and reducing the difficulty of operation and construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

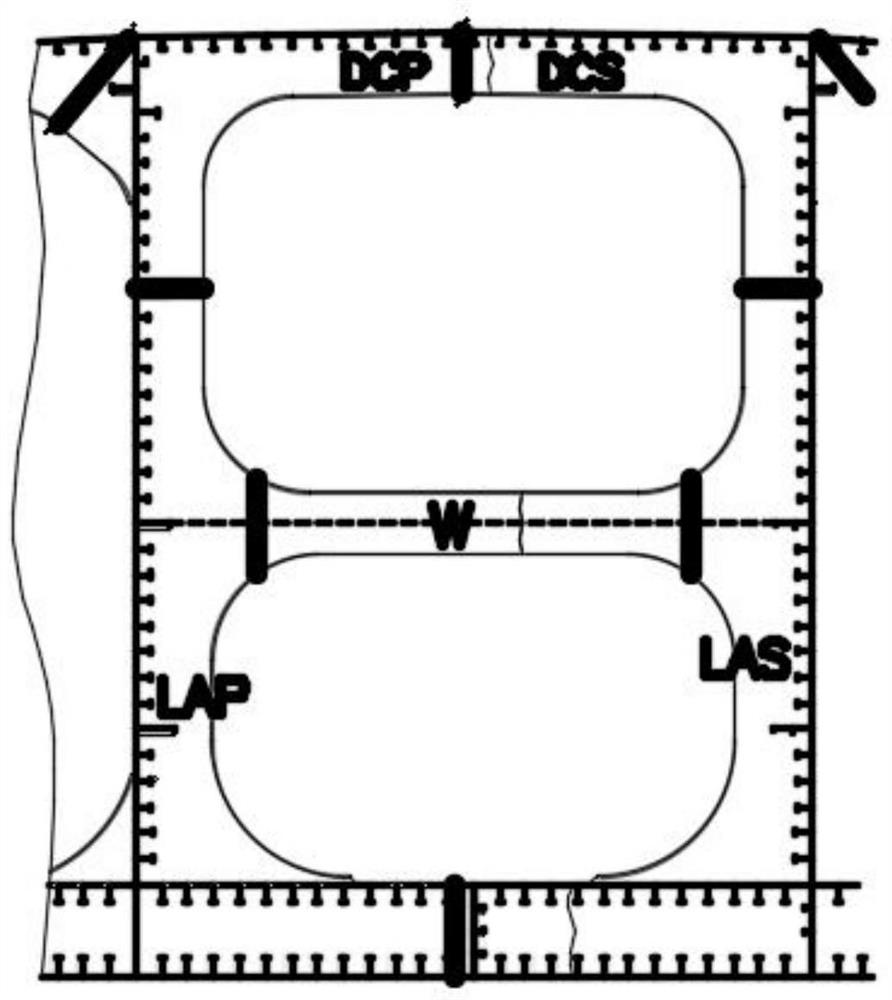

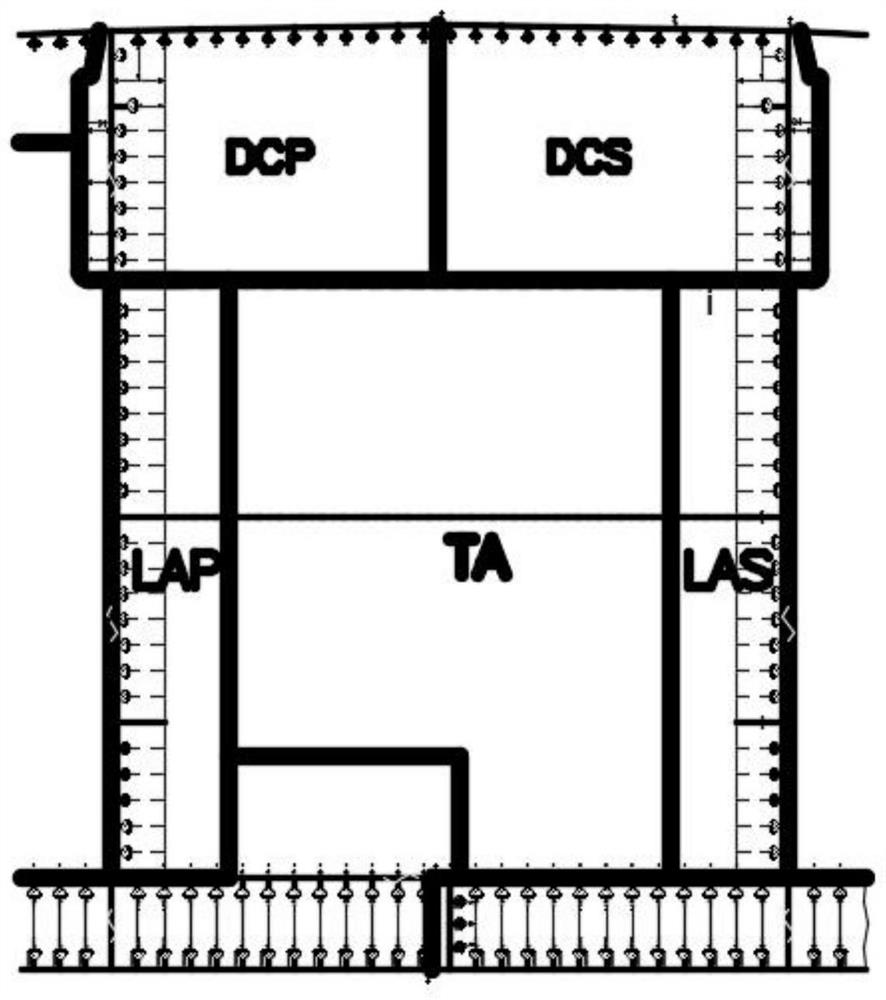

[0037] Please refer to the attached figure 1 , 2 , of which, attached figure 1 , 2 The segmentation process of the cargo oil tank in the VLCC provided by the embodiment of the present application is respectively shown, and the cargo oil tank in the VLCC is divided into several groups of segments along the length direction:

[0038] Segments include: upper deck, longitudinal bulkheads, intermediate structural segments:

[0039] Divide the upper deck into two sections DCS and DCP along the plane of symmetry;

[0040] Divide the longitudinal bulkhead into two segments, LAP and LAS, along the plane of symmetry;

[0041] The intermediate structural section is located between the two sections of the longitudinal bulkhead.

[0042] formed as figure 1 DCS, DCP, LAP, LAS and beam structure in the figure 1 Indicated by the letter W) or formed as figure 2 DCS, DCP, LAP, LAS and tight transverse bulkheads in the figure 2 Indicated by the letter TA).

Embodiment 2

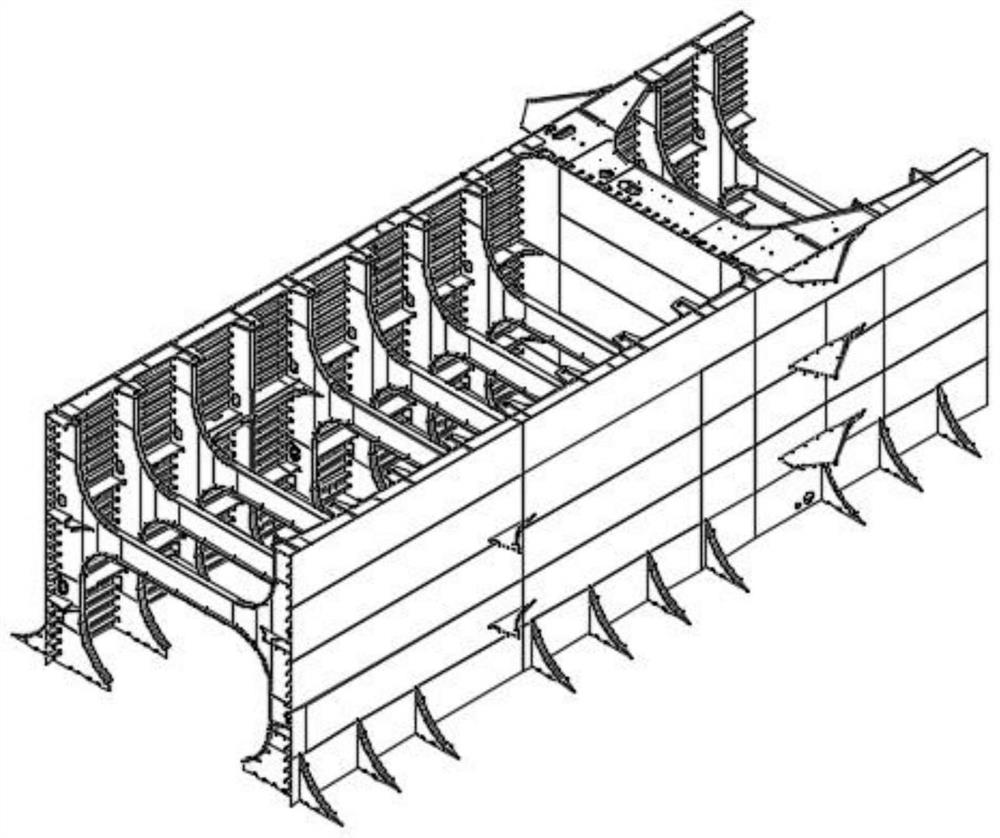

[0044] combined with Figure 1-4 , the present embodiment provides a cargo oil hatch type loading process in VLCC, which is carried out in sections as in Embodiment 1: the loading process includes the following steps:

[0045] S1. Pre-folding:

[0046] Door-to-door fixed offer P.E:

[0047] Each segment of DCS and each segment of DCP are individually P.E with the deck as BASE to form the total DCS segment and the total DCP segment:

[0048] Then turn both the DCS total section and the DCP total section 180°, and then perform P.E to get the door-to-door model;

[0049] Bottom-type fixed offer P.E:

[0050] Perform P.E on each section of LAP with the bulkhead as BASE to form the total section of LAP;

[0051] Turn over the total section of LAP by 90° and perform P.E with the intermediate structure section to form intermediate one;

[0052] Each segment of the LAS is P.E with the bulkhead as BASE to form the total LAS segment, and then the total LAS segment is turned 90° and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com