Digital rock core acoustic characteristic analysis method at different temperatures

A digital rock core and analysis method technology, applied in the field of rock physics, can solve problems such as differences in the physical properties of rock cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

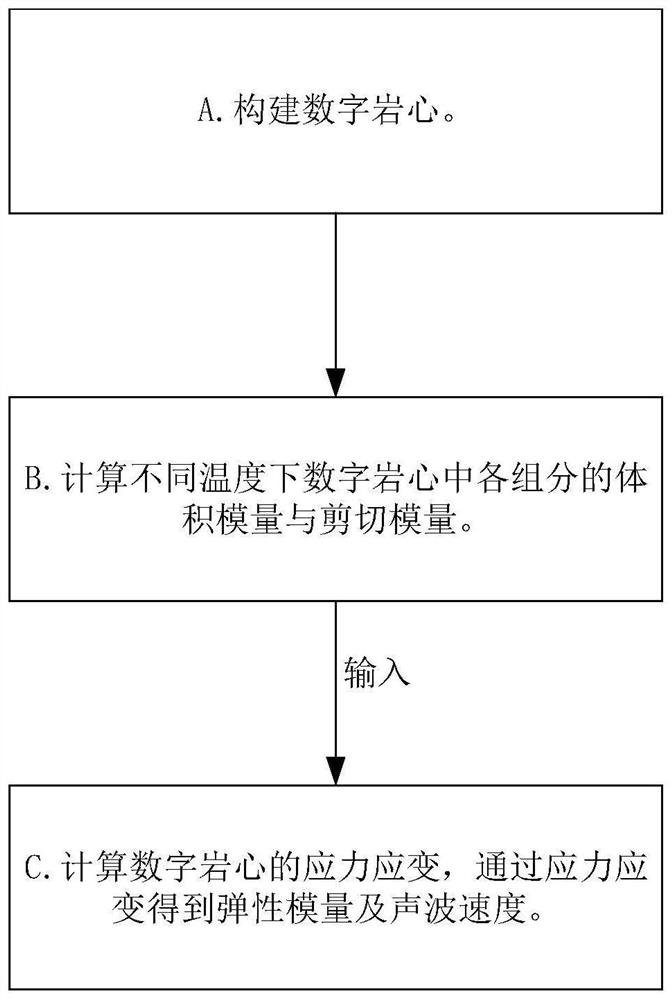

[0038] Embodiment 1, see attached figure 1 , the method for analyzing the acoustic characteristics of digital rock cores at different temperatures, comprising the following steps:

[0039] A. Construction of multi-component 3D digital cores.

[0040] A1. X-CT scanning equipment is used to scan the core to obtain a tomographic CT image, and reconstruct it to obtain a three-dimensional grayscale digital core.

[0041] A2. Combining QEMSCAN technology to process the three-dimensional grayscale digital core to construct a multi-component (multi-mineral, pore) digital core. The specific methods for processing the three-dimensional grayscale digital core include: representative core analysis, filtering, multi-threshold segmentation, etc.

[0042] B. Calculate the bulk modulus and shear modulus of each component in the digital core at different temperatures.

[0043] In this example, starting from the definition of Anderson-Gruneisen parameters and thermoelastic parameters, the re...

Embodiment 2

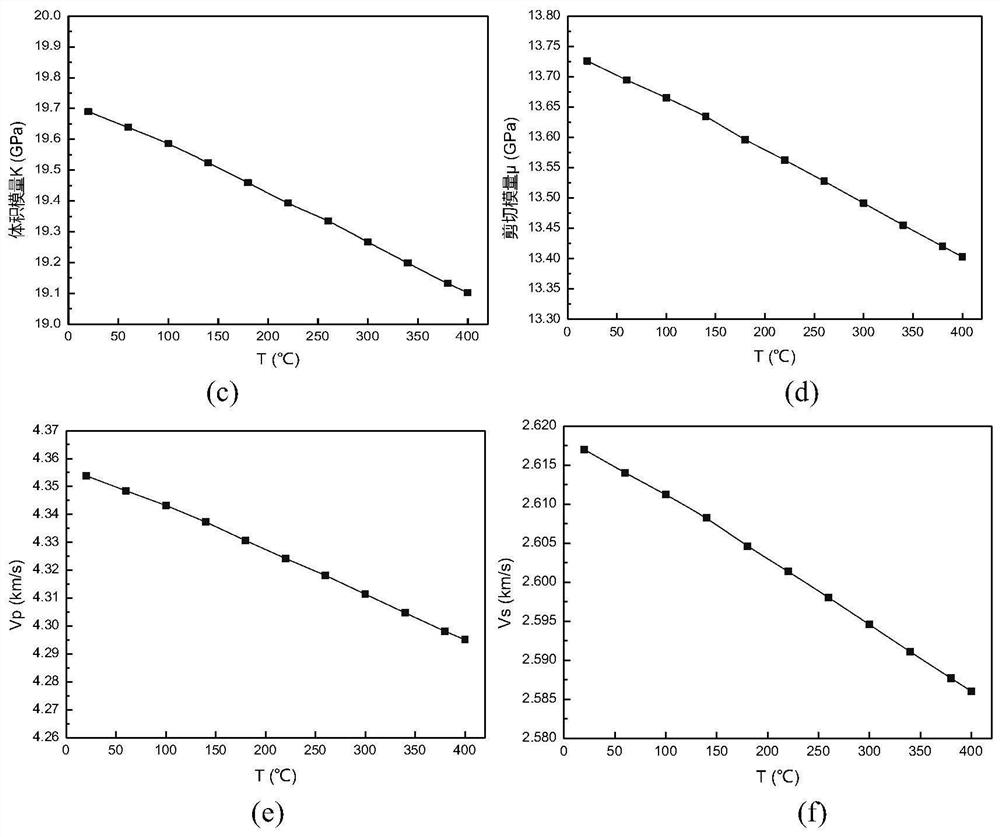

[0066] Example 2, on the basis of Example 1, the shale is simulated. During the simulation, the temperature is set at 10°C-400°C, and the simulation is performed every 50°C.

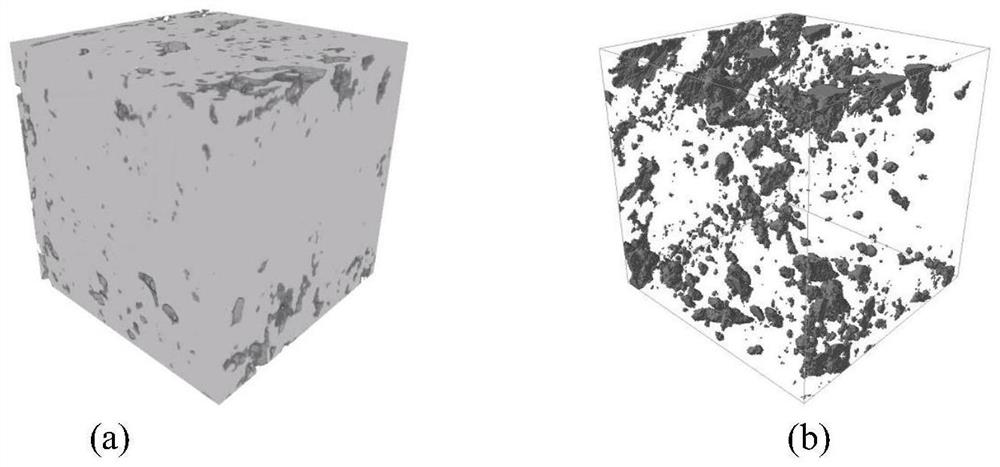

[0067] Such as figure 2 as shown, figure 2 a is a multi-component 3D digital core of shale constructed by X-CT scanning technology combined with QemScan mineral composition testing experiment, which contains pores, kerogen, clay, quartz and iron ore, figure 2 b is the pore space of the shale digital core; for example image 3 As shown in c-f, with the increase of temperature, the bulk modulus, shear modulus and P-s wave velocity will all decrease, but the decrease is not large.

[0068] In this example, shale is taken as an example to carry out numerical simulation of acoustic characteristics at different temperatures. In fact, for any other lithology including hot dry rock, the method proposed by the present invention is feasible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com