Virtual simulation method for judging bolt breakage under collision working condition

A virtual simulation and bolt technology, which is applied in the field of virtual simulation for judging bolt fracture under collision conditions, can solve problems such as the effect that cannot be used to predict the risk of bolt fracture, and achieves improved processing speed, accurate mechanical response, and improved efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

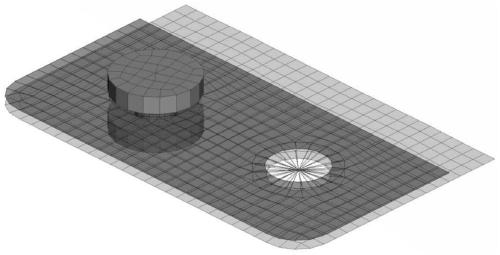

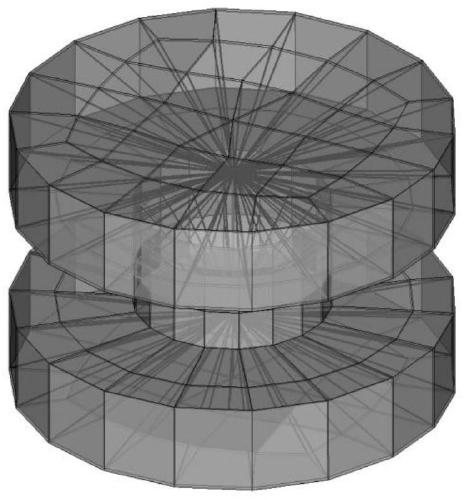

[0039] Below, the present invention will be further described by the embodiment of the battery pack mounting bolt on the electric vehicle in conjunction with the accompanying drawings:

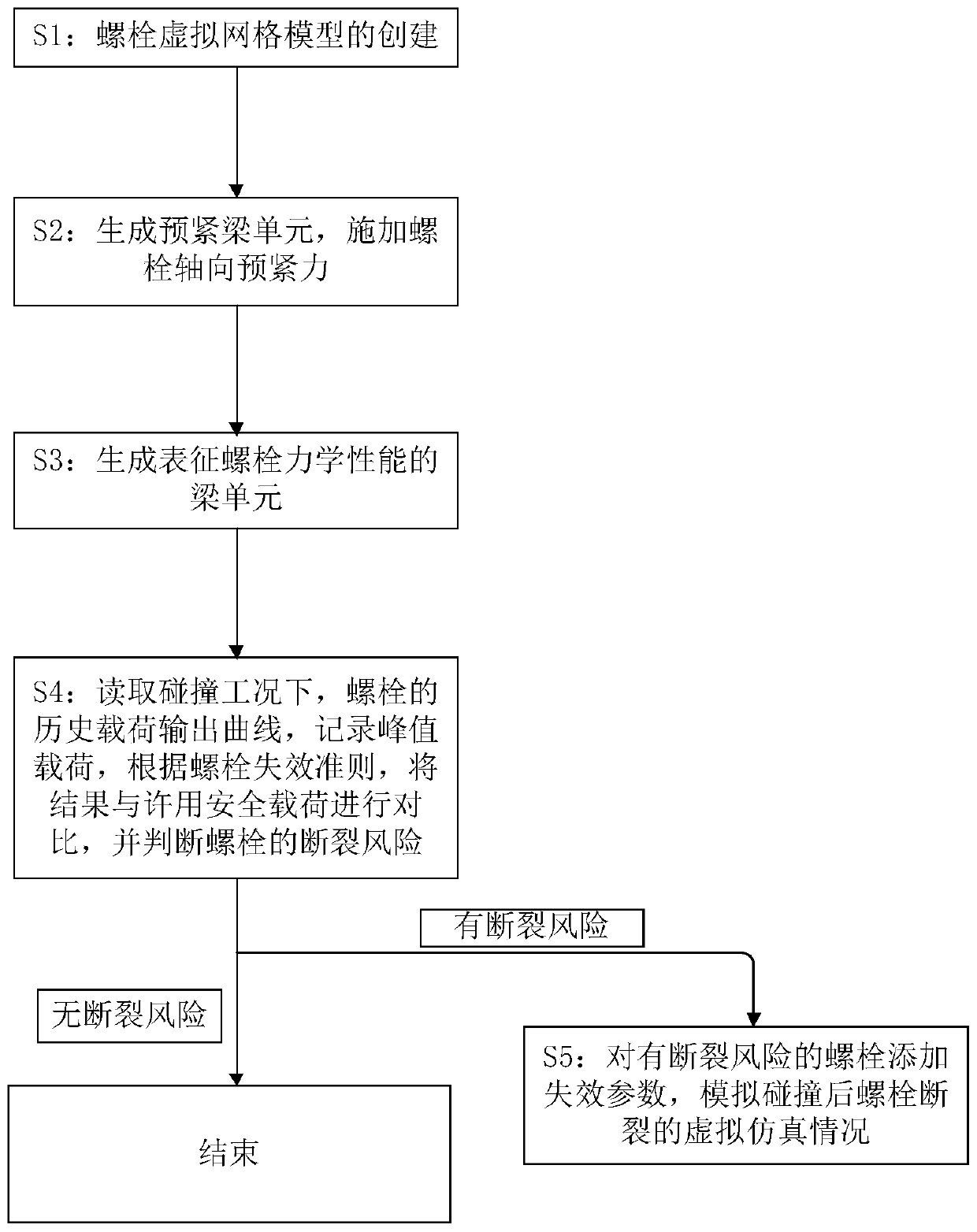

[0040] Such as Figure 1-Figure 14 As shown, a virtual simulation method for judging bolt fracture under collision conditions, the specific steps are as follows:

[0041] S1: Create a bolt virtual mesh model. In the finite element pre-processing software, according to the geometrical outline size parameters of the input bolts, create a bolt virtual mesh model of a pair of screws and nuts in batches. Since the geometric dimensions of the nut and the screw are relatively The size of the normal grid division is small, so as not to affect the calculation time step of the overall model, the bolt virtual grid model is assigned to the rigid body material.

[0042] Among them, the parameters of the geometric outer contour size include fixed parameters and variable parameters, and the variable paramet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com