Trisection grooving prefabrication method for disc, blade and shaft integrated turbine rotor with ultrahigh rotation speed

A technology of turbine rotor and analysis method, which is applied in the field of aviation auxiliary power, can solve the problems of products and personnel threats around debris, and achieve the effects of optimizing starter performance, high application value, and reducing the number of tests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Taking a certain type of air turbine starter as an example, the containment capacity of the containment ring needs to be verified through accurate turbine rotor rupture speed, that is, the turbine rotor is broken at a specified speed by slotting, and the broken fragments hit the containment ring to verify The containment capacity of the containment ring. How to accurately obtain the rupture speed of the turbine rotor is the core of the containment test.

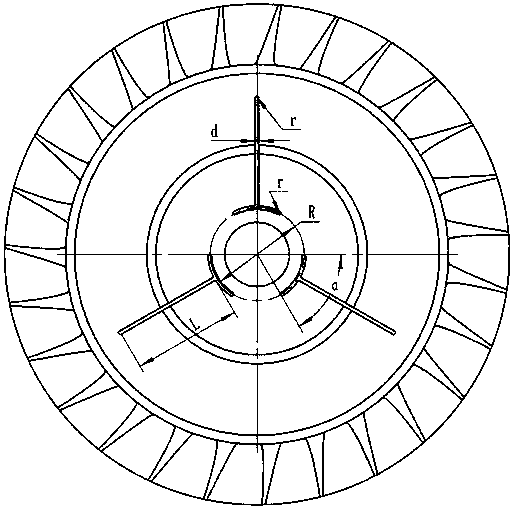

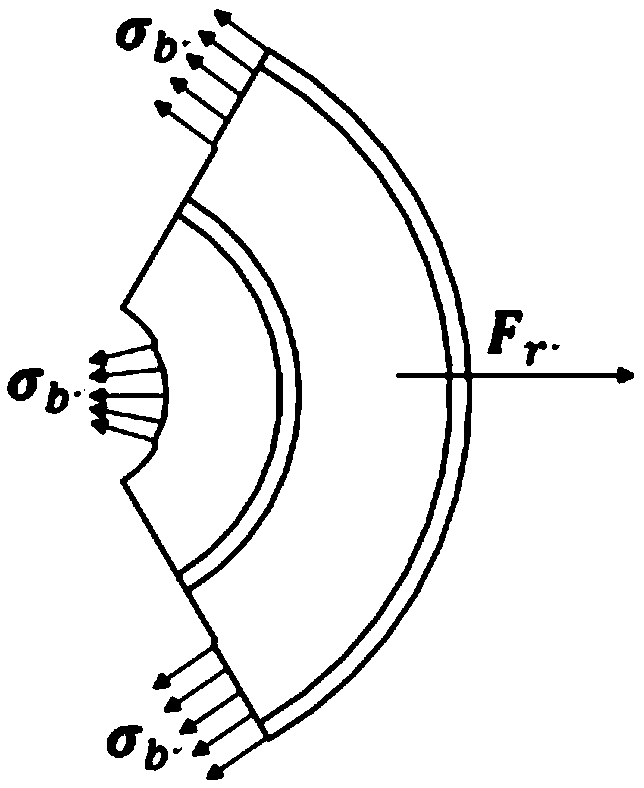

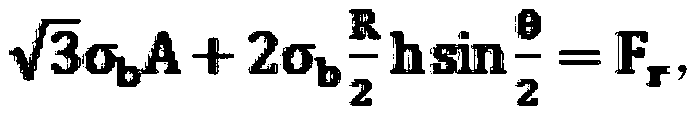

[0020] (1) Obtain the relevant mechanical performance parameters of the turbine rotor material through the material mechanical performance test, and provide data support for theoretical calculation and simulation modeling. According to the structural characteristics of the turbine rotor of this type of air turbine starter, the stress analysis of one-third of the turbine rotor is carried out, and the simplified average stress calculation method is used Determine the initial slotting position R=13 and the circumferenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com