Method for computing bending rigidity of disc and drum combination interface of rotor of aero-engine

An aero-engine, bending stiffness technology, applied in the direction of calculation, special data processing applications, instruments, etc., can solve problems such as time-consuming and expensive, unable to reflect the influence law of the interface stiffness of the disk-drum combination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

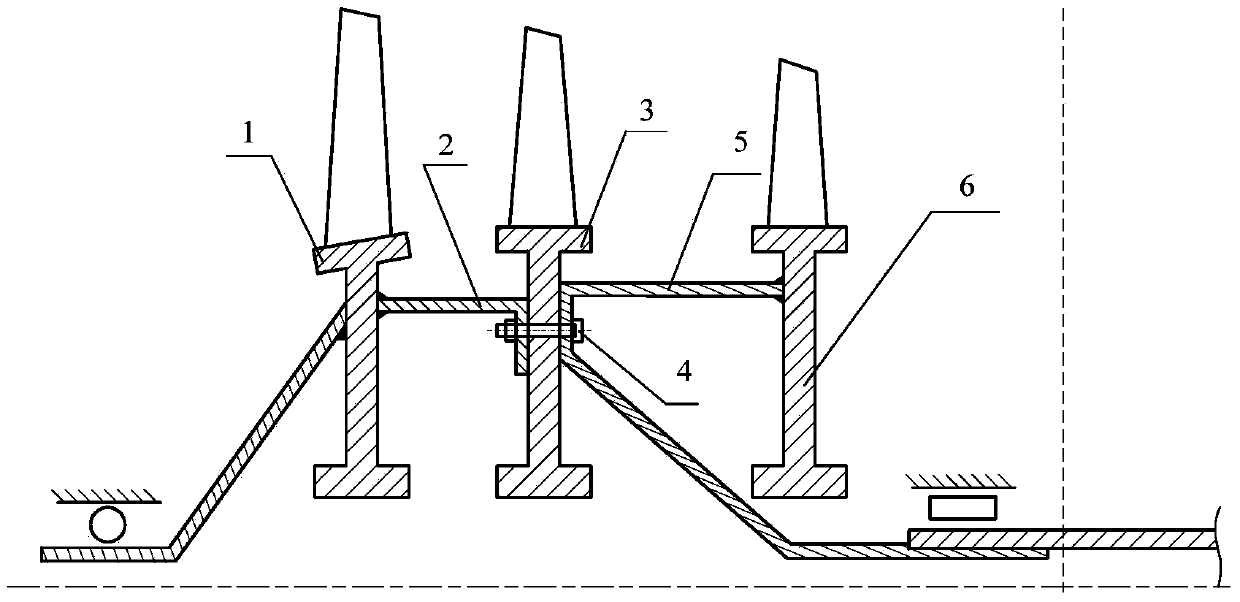

[0123] by Figure 5 The structural form of the combined structure of the drum shown in the finite element model is taken as an example to further illustrate the effectiveness of the method of the present invention. In this structure, the wheel disc is connected to the drums on the left and right sides by 30 bolts uniformly distributed along the circumference, and the structural parameters are listed in Table 1.

[0124] Table 1 The main parameters of a certain type of disc-drum combination structure

[0125]

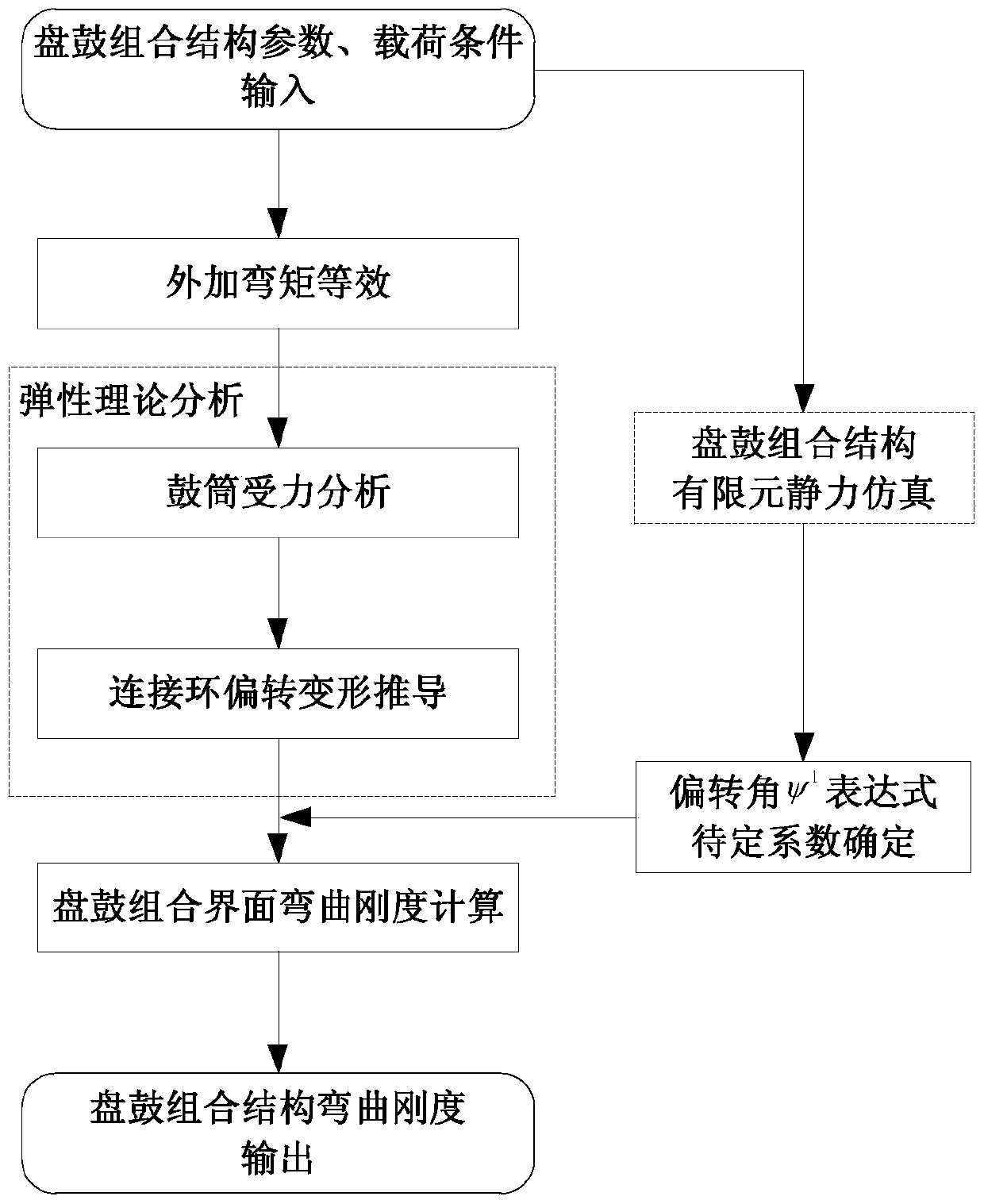

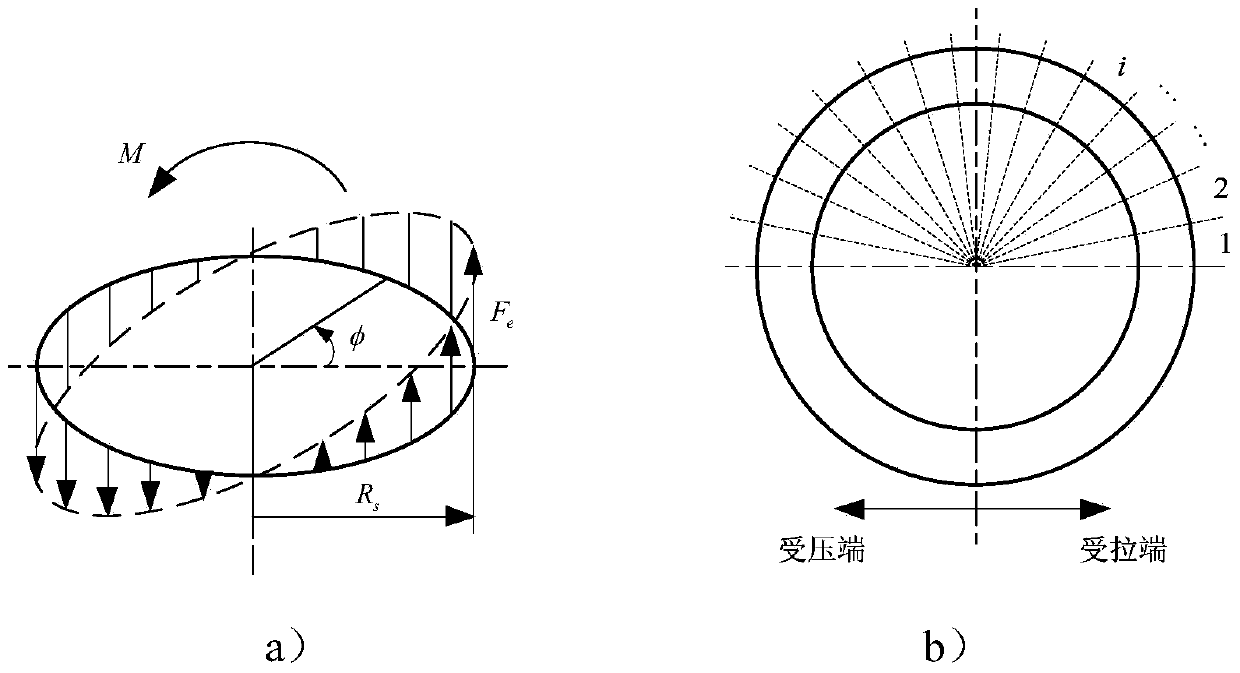

[0126] About the maximum deflection angle ψ of the drum connecting ring 1 The expression of and the bending stiffness K of the disc-drum combination interface m The expressions of the formulas listed in Step 1) Applied Bending Moment Equivalent, Step 2) Drum Force Analysis, Step 3) Derivation of Connecting Ring Deflection Deformation and Step 5) Calculation of Bending Stiffness of Drum Combination Interface can be directly obtained .

[0127] Here we focus on step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com