Online prediction method for remaining life of electromechanical equipment under situation of two-stage degradation

A technology of electromechanical equipment and prediction methods, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of inability to obtain more accurate predictions, unreasonable, etc., and achieve the effect of accurate online remaining life prediction results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

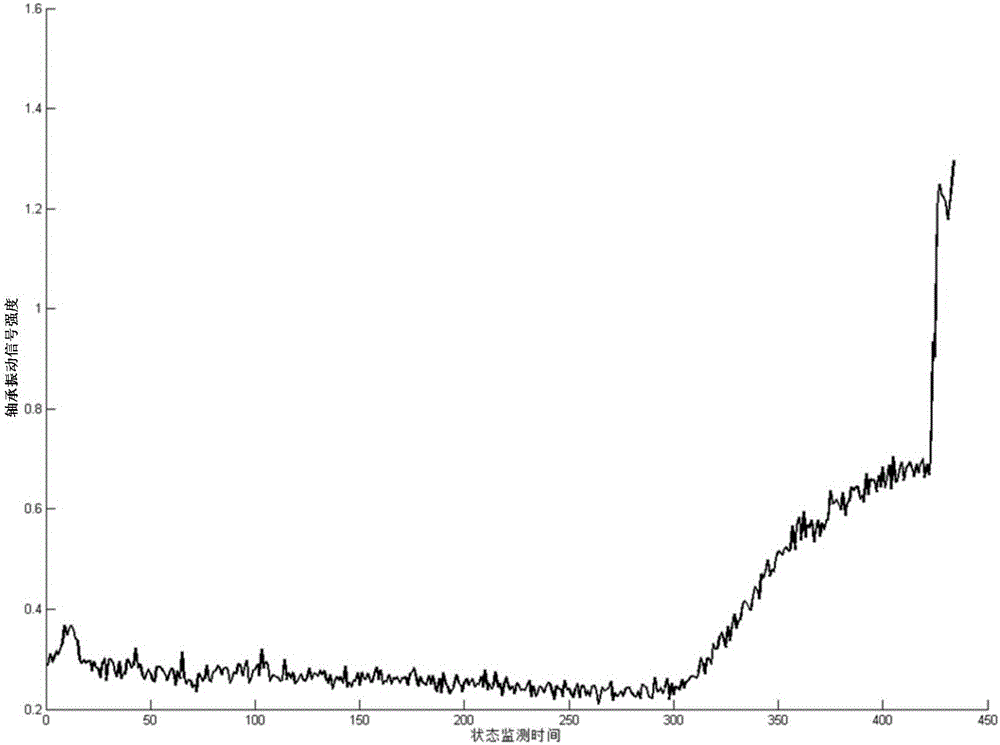

[0050]In the following example, a set of actual bearing degradation data from the PRONOSTIA experimental platform is used to illustrate the specific operation steps and the effect of the verification method.

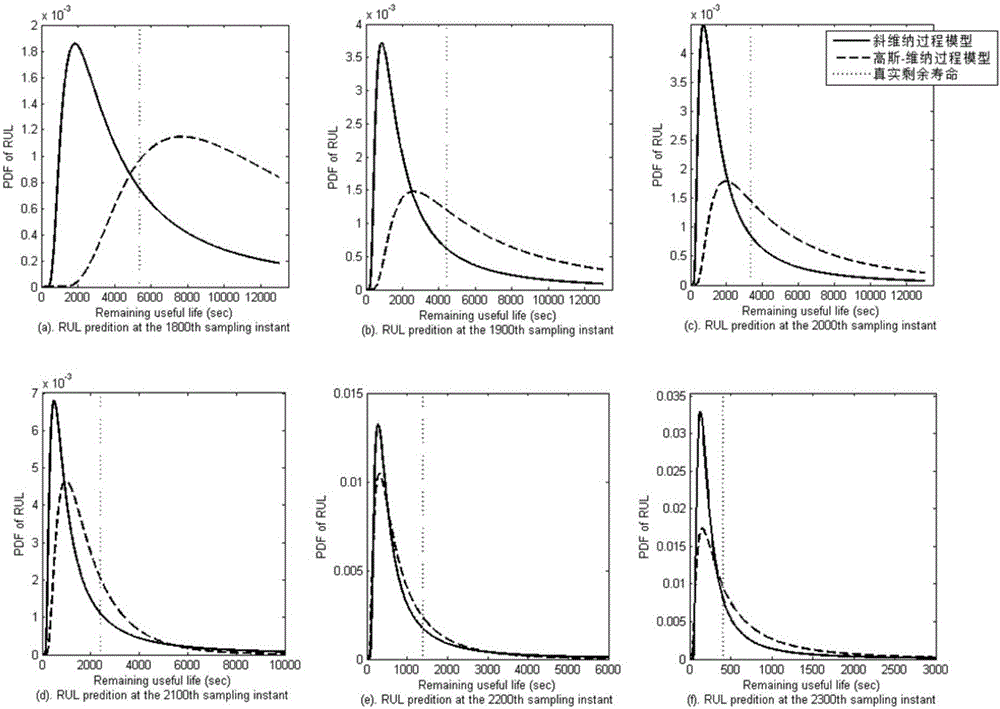

[0051] In the data collection of the degradation experiment, the experimenter collected 2560 vibration data at each sampling moment, and the sampling time interval was 10 seconds. At each sampling moment, this example calculates the root mean square value of 2560 vibration data as the feature value of each sampling moment, thus forming a new time series data for each bearing. The sampling interval of the RMS eigenvalue is 10 seconds. Since the model of the present invention is inspired by the adaptive Gauss-Wiener process model, the difference in performance between the two will be compared in this example.

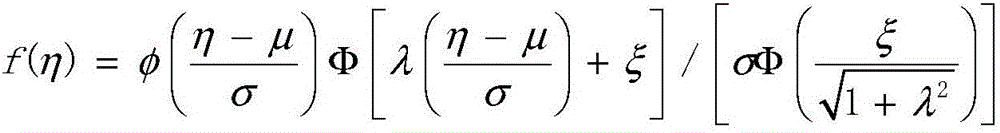

[0052] Step 1: Establish a perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com