Finite element analysis method for composite self-thermal insulation wall

An analysis method and finite element technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as blank specifications, difficult control of construction quality, and obstacles to the development and application of new composite self-insulating blocks. Achieve the effect of improving test quality and avoiding invalid tests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further explained below in conjunction with the drawings.

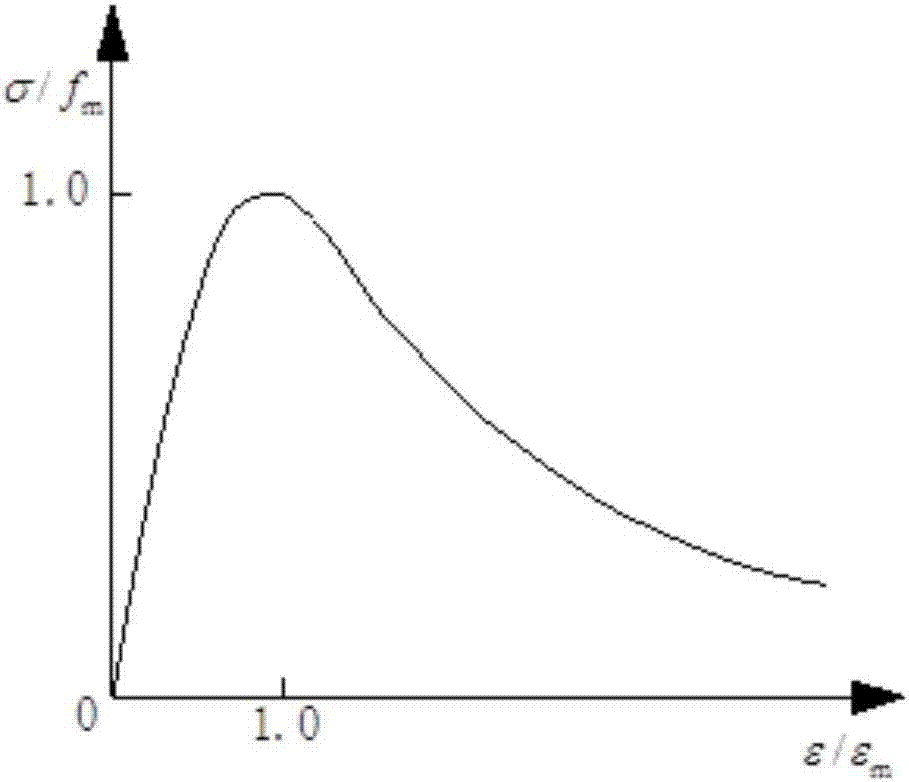

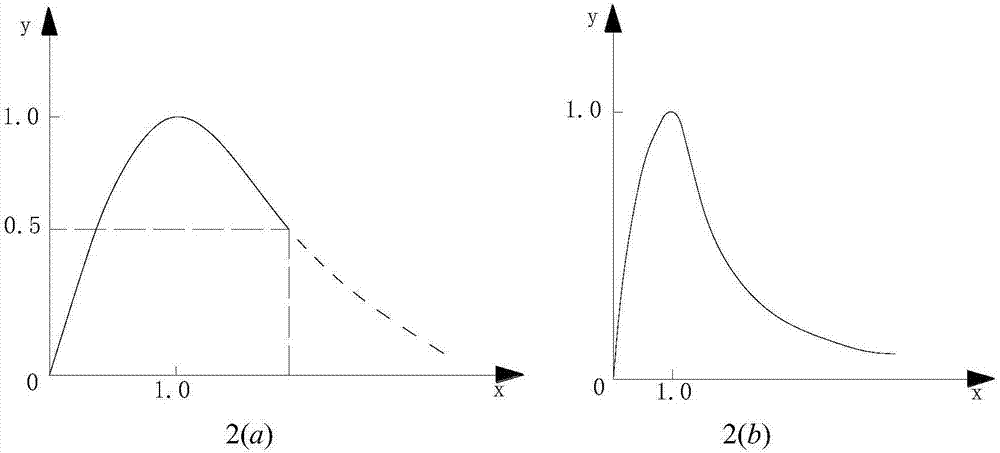

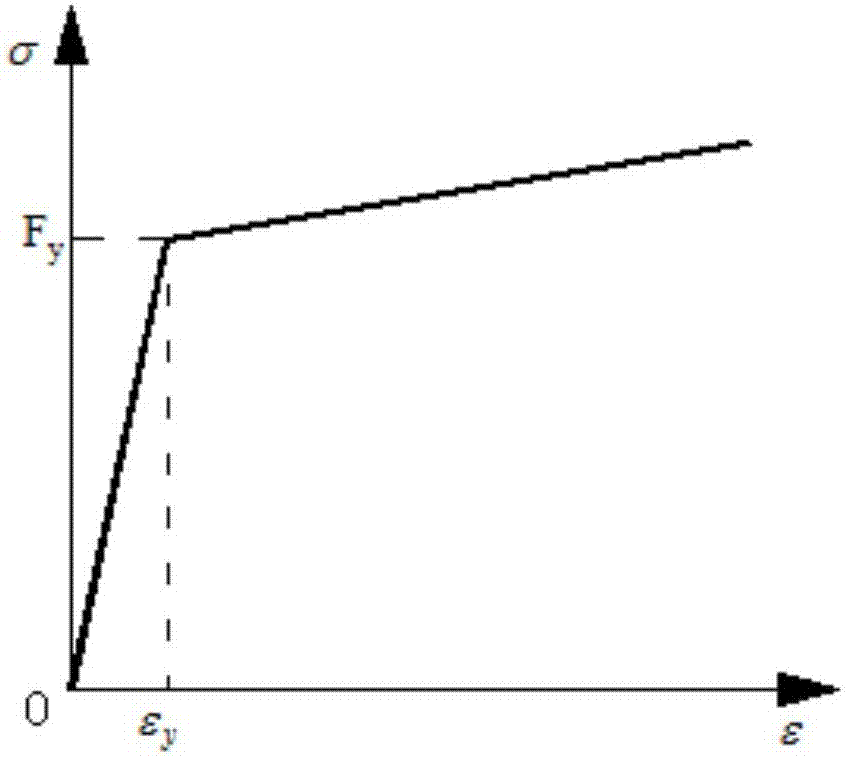

[0045] A finite element analysis method for composite self-insulating walls. The wall is made up of composite self-insulating blocks, concrete and steel bars. First, the continuity, isotropy, and uniformity assumptions are made on the wall. At the same time, the slip between the steel bar and the concrete in the wall is ignored; secondly, the wall is modeled by a monolithic model. After defining the masonry wall constitutive, concrete constitutive and steel bar constitutive, the concrete damage plastic model is selected for the wall Perform nonlinear finite element analysis on the volume. The method will be described in detail below.

[0046] 1. Assumptions

[0047] The force of masonry structure is more complicated, so it is necessary to make certain assumptions in the finite element simulation analysis of masonry structure. The assumptions adopted in this case are as follows:

[0048] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com